Method for uniformly and fast depositing thin film on surface of continuous fiber/strip

A continuous fiber and fiber filament technology is applied in the field of high-speed and uniform deposition of metal/compound films to achieve the effects of high-speed and high-uniform deposition of films, increased density, and low damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

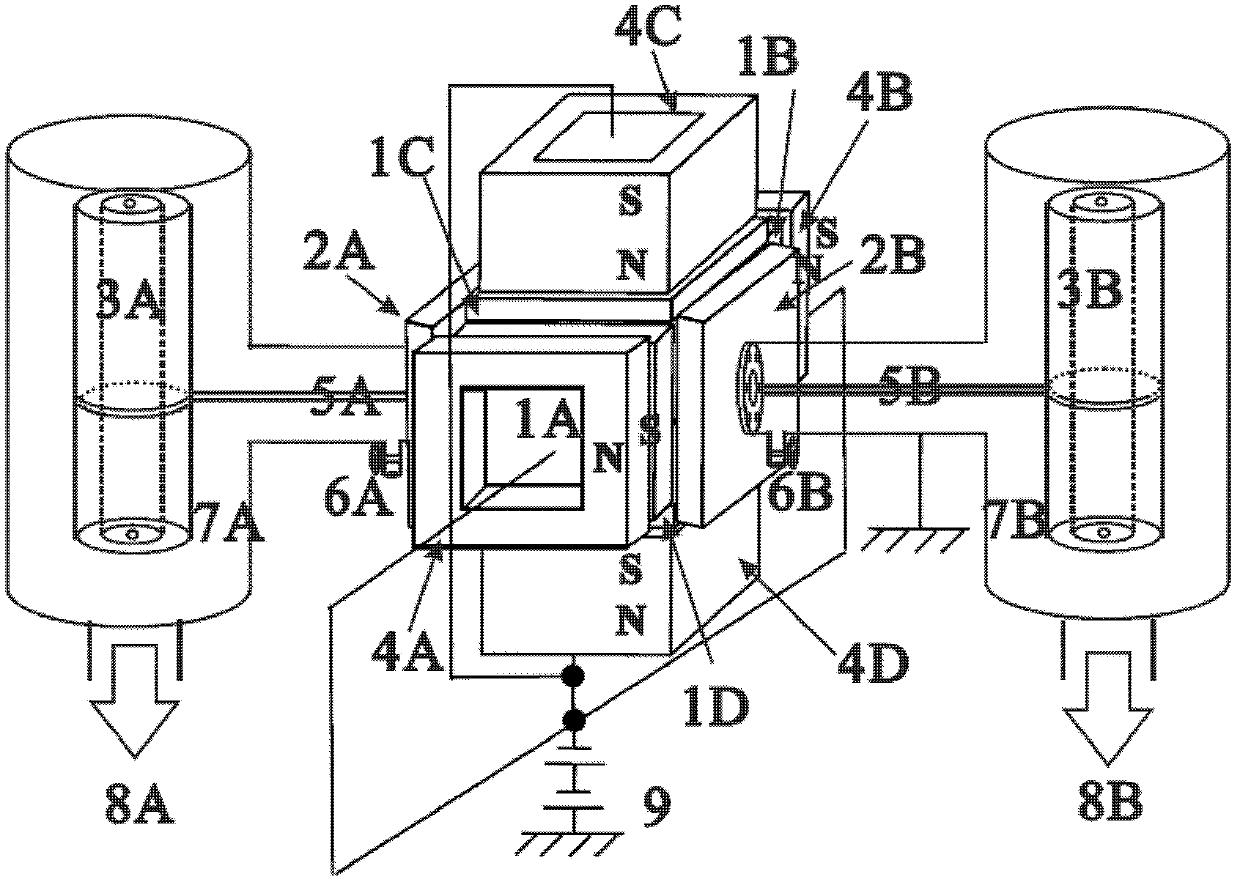

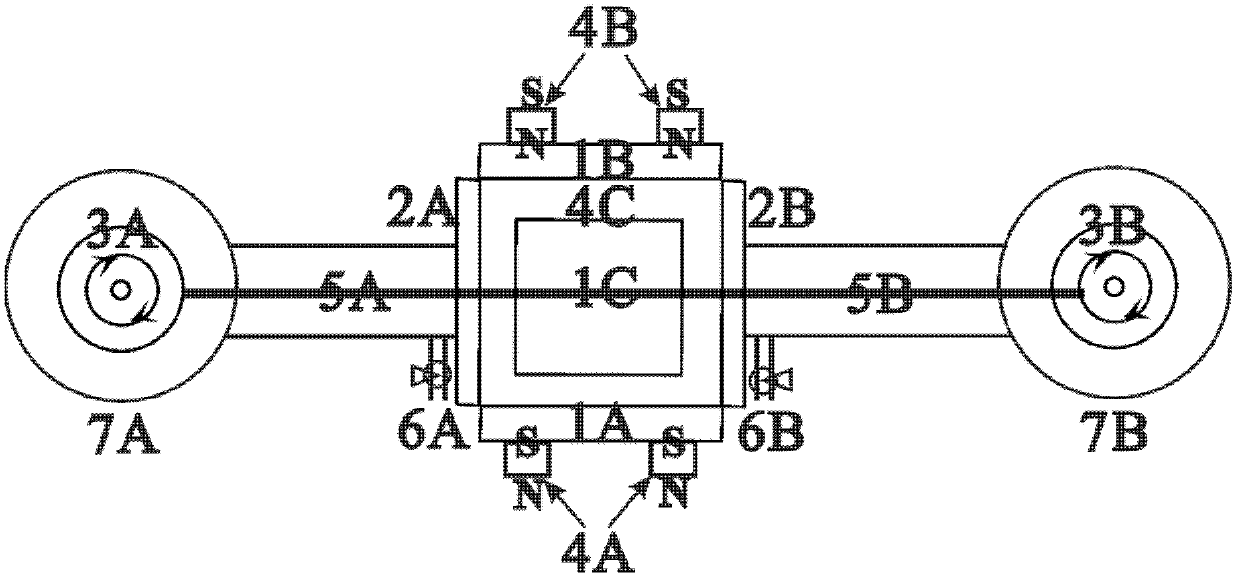

[0044] Such as Figure 1-2 As shown, the entire vacuum system of the device of the present invention mainly includes: the first group of targets (the first group of target A side 1A and the first group of target B side 1B), the second group of targets (the second group of target C side 1C and the second group of targets D surface 1D), shielding plates at both ends (shielding plate 2A and shielding plate 2B), tension-controllable winding workpiece turret (injection turret 3A and sample output turret 3B), magnet System (magnet system A part 4A, magnet system B part 4B, magnet system C part 4C and magnet system D part 4D), filaments / strips (fibers / strips at the inlet end 5A and filaments / strips at the outlet end belt 5B), sputter gas inlets (sputter gas inlet 6A and sputter gas inlet 6B), vacuum chambers (vacuum chamber 7A and vacuum chamber 7B), vacuum pumps (vacuum pump 8A and vacuum pump 8B ), magnetron sputtering DC / IF pulse power supply 9, etc., the specific structure is as...

Embodiment 2

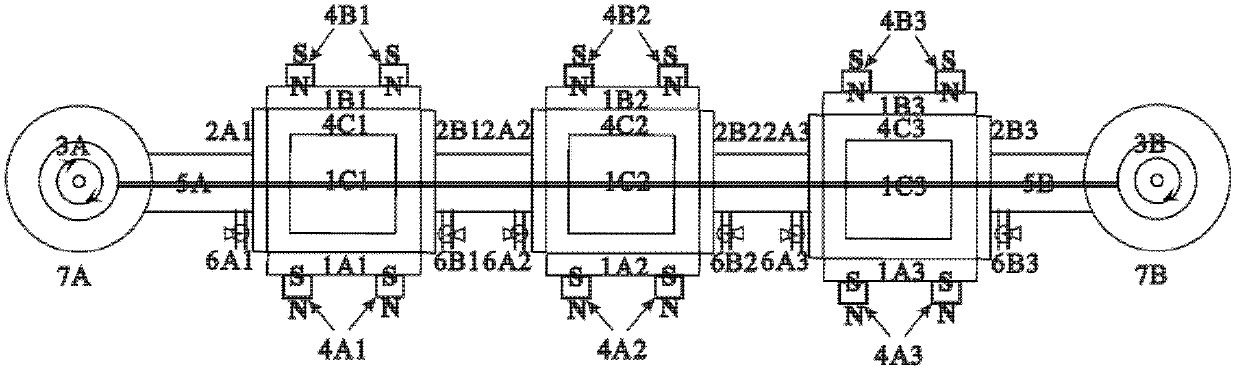

[0050] Such as image 3As shown, the device of the present invention can adopt a whole vacuum system composed of three (more) sealed cuboids / cubes and winding turret vacuum chambers, and the three sealed cuboids / cubes are connected to the winding turret in pairs, and the The turret 3A is connected to the left part of the first sealed cuboid / cube, the right part of the first sealed cuboid / cube is connected to the left part of the second sealed cuboid / cube, and the The right part is connected with the left part of the third sealed cuboid / cube, and the right part of the third sealed cuboid / cube is connected with the sampling turret 3B; the fiber filament / strip 5A at the injection end is wound on the sample turret 3A, the filament / strip 5B at the sample outlet is wound on the sample outlet turret 3B; the vacuum chambers 7A and 7B are connected to the sealed cuboid / cube, and the winding workpiece turret is located in it. In the first sealed cuboid / cube, the A surface 1A1 of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com