Preparation method for transmission electron microscope (TEM) specimen of cadmium zinc tellurium (CdZnTe) and metal interface

An electron microscope and metal interface technology, applied in the preparation of test samples, etc., can solve the problems of sample fragmentation and high rejection rate, and achieve the effect of preventing sample fragmentation, improving the success rate and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

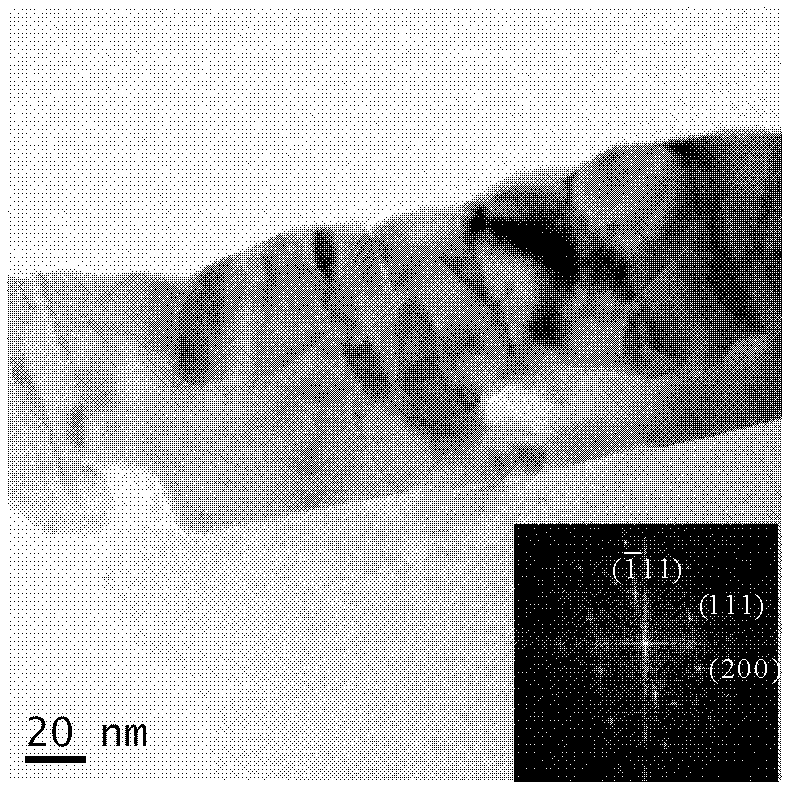

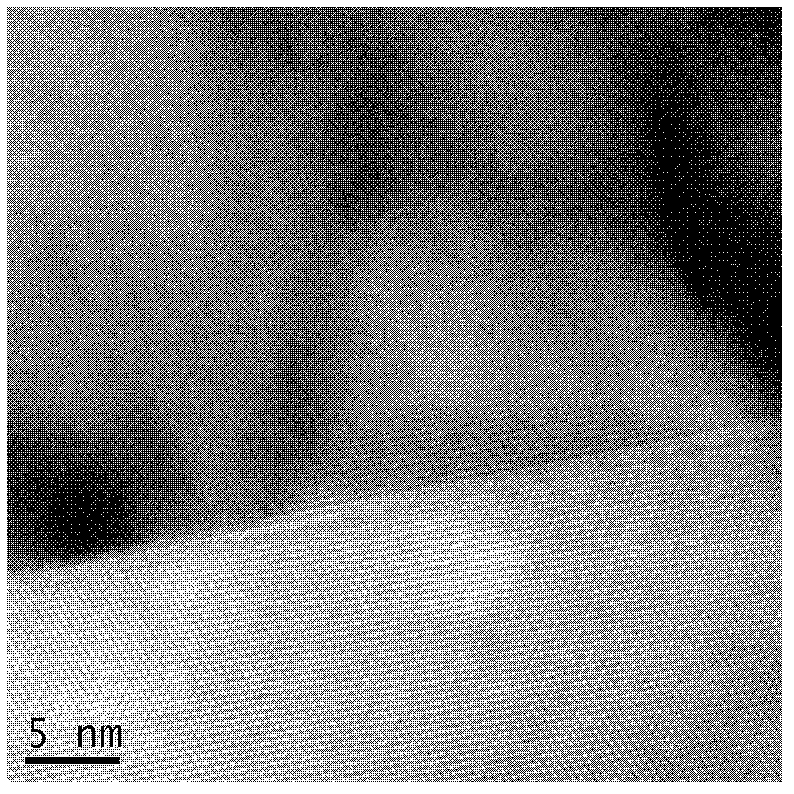

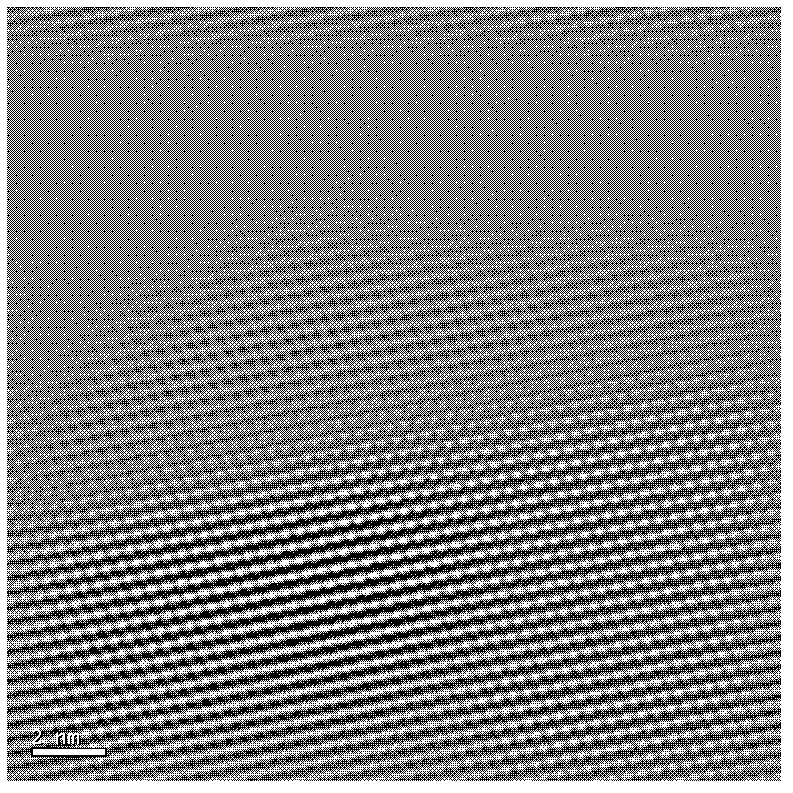

Image

Examples

Embodiment 1

[0018] Embodiment 1: In the first step, the CdZnTe crystal is wire-cut, and the cut wafers have a size of 3mm×5mm×0.7mm, a total of 3 pieces, and the wafers are cleaned and mechanically polished to obtain 3 CdZnTe wafers to be used.

[0019] The second step is to prepare Au electrodes in the ZHD-300 resistance evaporation coating machine. One of the samples is a double-sided coated electrode, and the rest of the samples are single-sided coated with an electrode thickness of 100nm. at 200°C for 5 minutes.

[0020] In the third step, the three wafers are bonded in such a way that the Au electrode layers are facing each other. The adhesive is Gatan G-1 glue, and the mixing ratio of soft and hard glue is 10:1. Bake on hot plate for 15 hours.

[0021] The fourth step is to use 2000# sandpaper to manually thin the sample to 100 μm. The thinning direction is along the normal direction of the bonding gap. network.

[0022] In the fifth step, use a manual grinder and 5000# sandpaper...

Embodiment 2

[0024] Embodiment 2: the first step, wire cutting is carried out to CdZnTe crystal, the wafer size that cuts out is 3mm * 5mm * 0.7mm, totally 5 pieces, wafer is cleaned, mechanically polished, in 2%Br-MeOH, wafer is carried out Corrosion to obtain 5 CdZnTe wafers to be used.

[0025] The second step is to prepare Au electrodes in the ZHD-300 resistance evaporation coating machine. One of the samples is a double-sided coated electrode, and the rest of the samples are single-sided coated with an electrode thickness of 100nm. at 200°C for 5 minutes.

[0026] In the third step, the three wafers are bonded in such a way that the Au electrode layers are facing each other. The adhesive is Gatan G-1 glue, and the mixing ratio of soft and hard glue is 10:1. Bake on hot plate for 20 hours.

[0027] The fourth step is to manually thin the sample to 100 μm with 3000# sandpaper, and the thinning direction is along the normal direction of the bonding gap. network.

[0028] In the fifth...

Embodiment 3

[0030] Embodiment 3: the first step, carry out wire cutting to CdZnTe crystal, the wafer size that cuts out is 3mm * 5mm * 0.7mm, totally 5 pieces, the wafer is cleaned, mechanically polished, in 2% Br-MeOH, wafer is carried out Corrosion to obtain 5 CdZnTe wafers to be used.

[0031] The second step is to prepare Al electrodes in a ZHD-300 resistance evaporation coating machine. One of the samples is a double-sided coated electrode, and the rest of the samples are single-sided coated with an electrode thickness of 100nm, and then undergo rapid annealing under a nitrogen atmosphere. at 200°C for 5 minutes.

[0032] In the third step, the three wafers are bonded in such a way that the Al electrode layers are facing each other. The adhesive is Gatan G-1 glue, and the mixing ratio of soft and hard glue is 10:1. After the bonding is completed, the sample is tightened with a clamp. Bake on hot plate for 20 hours.

[0033] The fourth step is to manually thin the sample to 100 μm w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com