Silicon solar battery front silver paste with wide high-temperature sintering window

A high-temperature sintering, silver paste technology, applied to conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problem of no proposed paste high-temperature sintering window performance, unreasonable temperature range setting, high-temperature sintering The problem of narrow window, etc., can increase the viscosity, reduce the ratio, and improve the conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

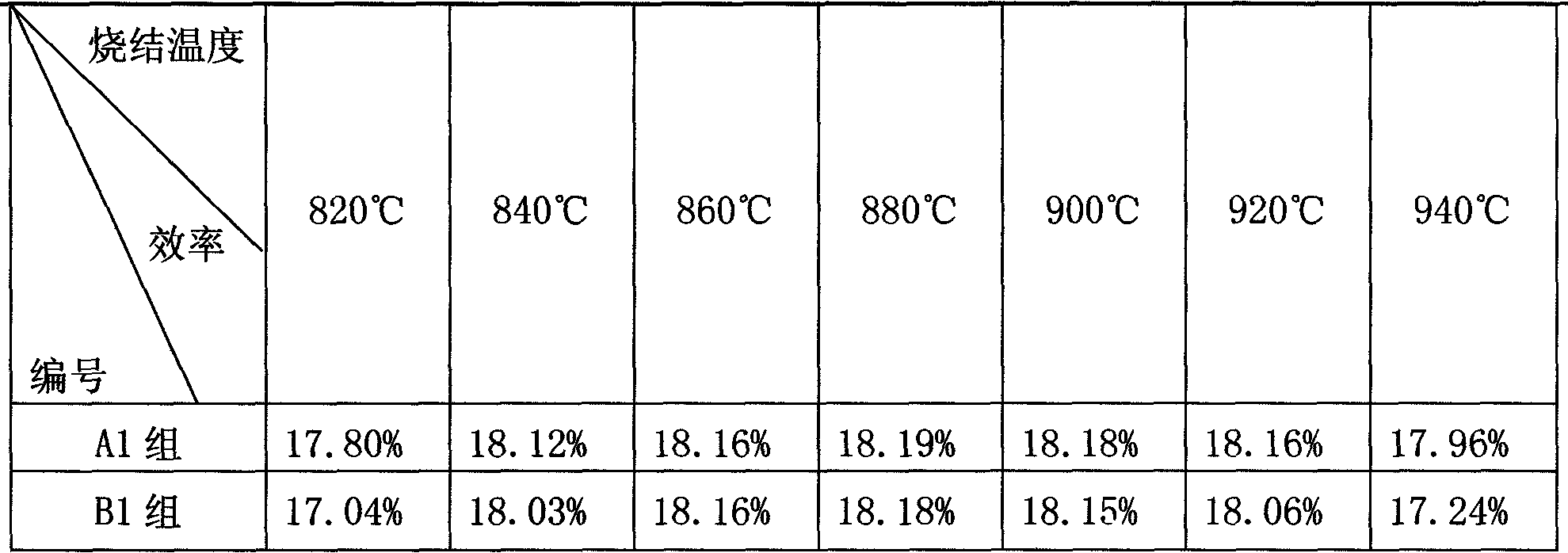

Embodiment 1

[0027] A kind of silicon solar cell front silver paste (preparation 100g) of wide high temperature sintering window, its production process is as follows:

[0028] Weigh 6g of silicon dioxide with an average particle size of 40nm, weigh 92g of glass powder with a particle size of 1-6μm and a softening point of 440°C, and weigh 0.5-3μm of Bi 2 o 3 2g of the mixed material was ball-milled for 3 hours and dried to obtain the inorganic mixed additive.

[0029] The organic resin is weighed at 1-10% of the raw material weight, the solvent is 5-15% of the raw material weight, and the organic modification additive is weighed at 1-5% of the raw material weight, and stirred and mixed to obtain an organic carrier.

[0030] Slurry preparation: weigh 8g of inorganic mixed additives, 82g of silver powder, and 10g of organic vehicle, stir and disperse evenly in a container, and then perform three-roll grinding to obtain a silver paste with a slurry fineness of less than 10 μm.

[0031] Use...

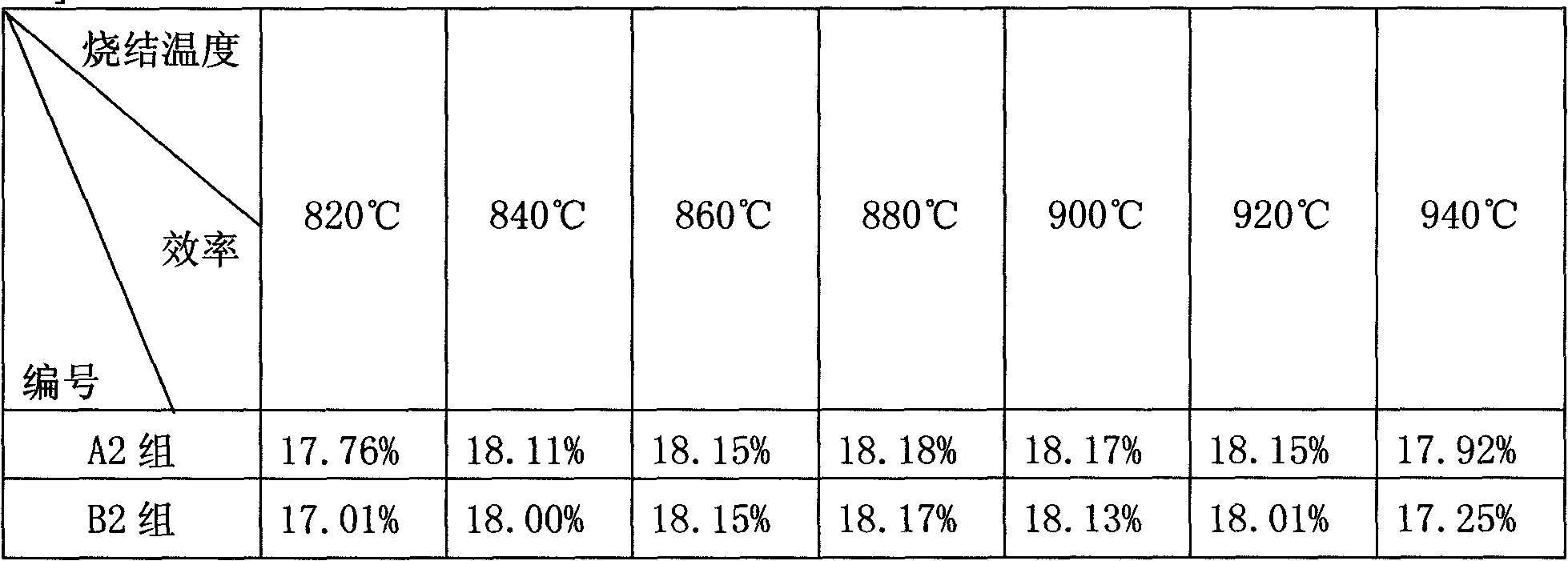

Embodiment 2

[0036] A kind of silicon solar cell front silver paste (preparation 100g) of wide high temperature sintering window, its production process is as follows:

[0037] Weigh 12g of silicon dioxide with an average particle size of 80nm, weigh 85g of glass frit with a particle size of 1-6μm and a softening point of 420°C, and weigh Bi with a particle size of 0.5-3μm. 2 o 33g of the mixed material was ball-milled for 3 hours and dried to obtain the inorganic mixed additive.

[0038] The organic resin is weighed at 1-10% of the raw material weight, the solvent is 5-15% of the raw material weight, and the organic modification additive is weighed at 1-5% of the raw material weight, and stirred and mixed to obtain an organic carrier.

[0039] Slurry preparation: Weigh 5g of inorganic mixed additives, 85g of silver powder, and 10g of organic vehicle, stir and disperse evenly in a container, and then perform three-roll grinding to obtain a silver paste with a slurry fineness of less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com