Method for preparing polypyrrole nanometer wire-graphene composite material

A technology of polypyrrole nanowires and composite materials, which is applied in the field of preparation of polypyrrole nanowires-graphene composite materials, can solve the problem of low electrical conductivity at the same time, and achieve the effects of short time, controllable operation process and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Prepare the electrolyte: weigh 3.08g disodium hydrogen phosphate and 0.08g lithium perchlorate, add 50ml deionized water, and prepare a mixed electrolyte containing 0.2M disodium hydrogen phosphate and 0.01M lithium perchlorate, Stir with a magnetic stirrer for 30 min. According to the ratio of pyrrole and graphene mass percentage of 90%:10%, weigh 0.5g (0.075M) pyrrole monomer and add it to the electrolyte, and stir it magnetically for 10min.

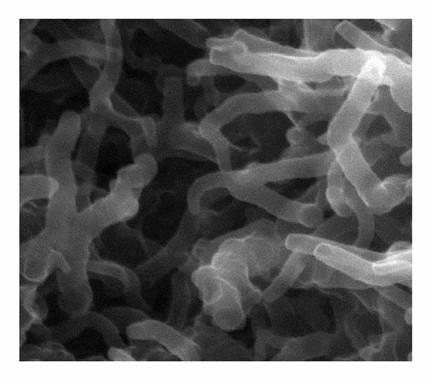

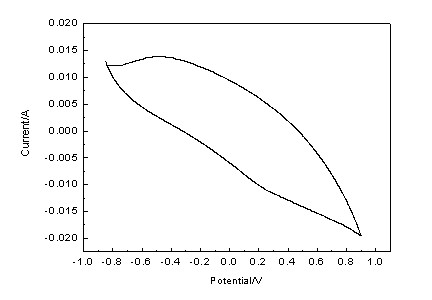

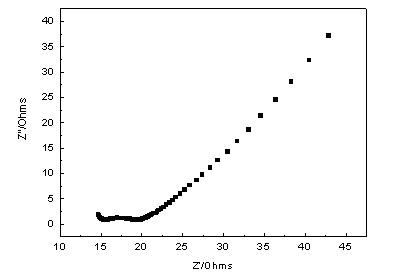

[0034] (2) Preparation of polypyrrole nanowire / graphene composite material: 0.06 g of graphene was added to the above solution, ultrasonicated for 30 min and left to stand to obtain a uniformly dispersed mixed solution. The polymerization experiment was carried out in a three-electrode system controlled by an electrochemical workstation, with a nickel sheet as the working electrode, a platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. Using the constant potential method, t...

Embodiment 2

[0038] (1) Prepare the electrolyte: weigh 3.08g disodium hydrogen phosphate and 0.08g lithium perchlorate, add 50ml deionized water to prepare a mixed electrolyte containing 0.2M disodium hydrogen phosphate and 0.01M lithium perchlorate, Stir with a magnetic stirrer for 30 min. According to the ratio of pyrrole and graphene mass percentage of 60%: 40%, weigh 0.5g (0.075M) pyrrole monomer into the electrolyte solution, and stir magnetically for 10min.

[0039] (2) Preparation of polypyrrole nanowire / graphene composite material: 0.34 g of graphene was added to the above solution, ultrasonicated for 30 min, and left to stand to obtain a uniformly dispersed mixed solution. The polymerization experiment was carried out in a three-electrode system controlled by an electrochemical workstation, with a nickel sheet as the working electrode, a platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. Using the constant potential method, the ...

Embodiment 3

[0043] (1) Prepare the electrolyte: weigh 3.08g disodium hydrogen phosphate and 0.08g lithium perchlorate, add 50ml deionized water to prepare a mixed electrolyte containing 0.2M disodium hydrogen phosphate and 0.01M lithium perchlorate, Stir with a magnetic stirrer for 30 min. According to the ratio of pyrrole and graphene mass percentage of 80%:20%, add 0.85g (0.125M) pyrrole monomer into the electrolyte, and magnetically stir for 10min.

[0044] (2) Preparation of polypyrrole nanowire / graphene composite material: 0.21 g of graphene was weighed and added to the above solution, ultrasonicated for 30 min and left to stand to obtain a uniformly dispersed mixed solution. The polymerization experiment was carried out in a three-electrode system controlled by an electrochemical workstation, with a nickel sheet as the working electrode, a platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. Using the constant potential method, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com