Tulobuterol patch and preparation method thereof

A technology of tulobuterol and patch, applied in the field of tulobuterol patch and preparation thereof, can solve the problems of not being suitable for nighttime asthma prevention and treatment, unable to play a long-term treatment, insufficient drug release in the later period, etc. Moderate viscosity, good solubility, simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

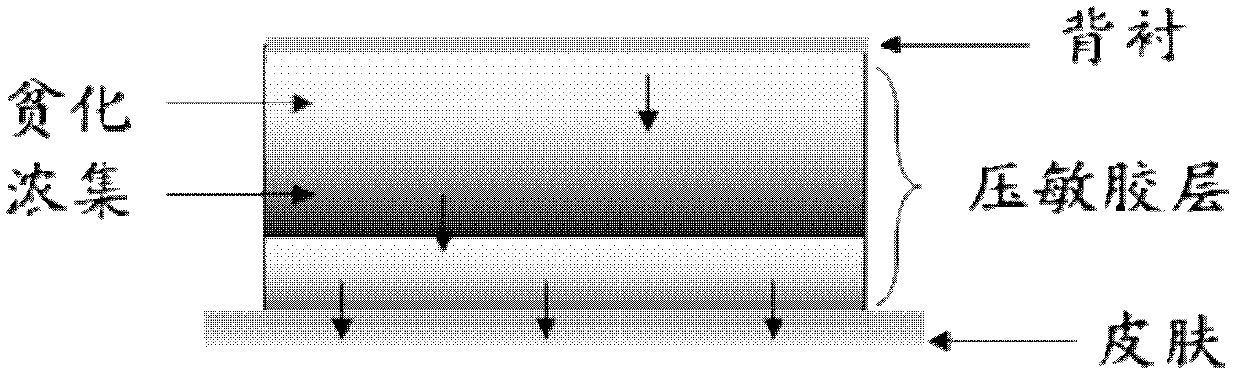

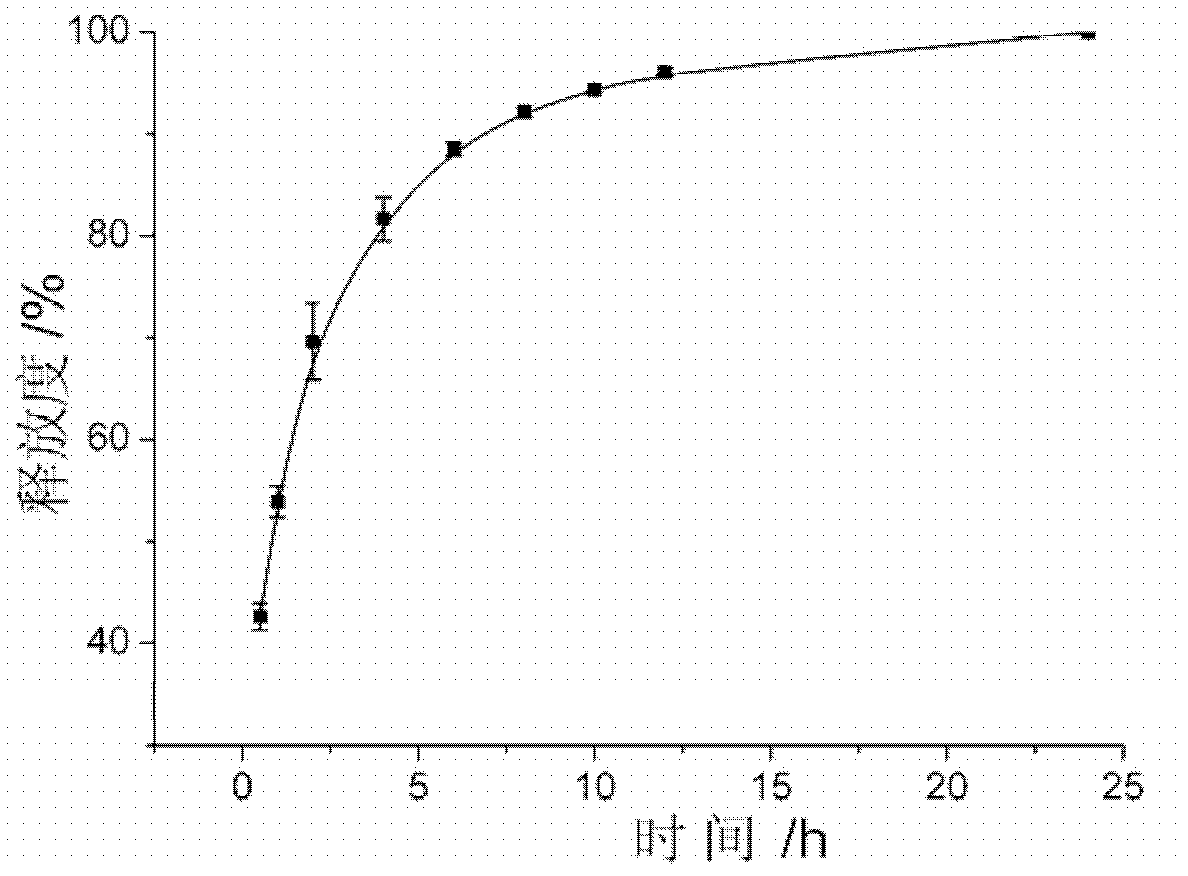

[0031] Embodiment 1, preparation tulobuterol controlled-release patch

[0032] Weigh high molecular weight polyisobutylene B50 (1.5g, Daelim, South Korea), low molecular weight polyisobutylene PB1300 (1g, Daelim, South Korea) and plasticizer naphthene oil NAPHSOL200 (1ml) of the prescription amount, in a 150ml round bottom flask, add n-hexane An appropriate amount of alkanes (accounting for about 50% of the solute mass) was heated at 50°C under reflux and stirred for 5 hours to form a uniform viscous semi-solid fluid. Then add an appropriate amount of tulobuterol, stir evenly, and make 8.4 mg / ml uniformly mixed drug-containing colloid. The patch was prepared according to the volume ratio of the drug-containing colloid coated by the inner and outer coatings of 2:1, wherein the inner layer was close to the backing (EH-1203, Kedebao Feather Nonwovens (Suzhou) Co., Ltd.), and the outer layer was close to the covering Film (anti-adhesive layer), first on the backing layer (4.5*11....

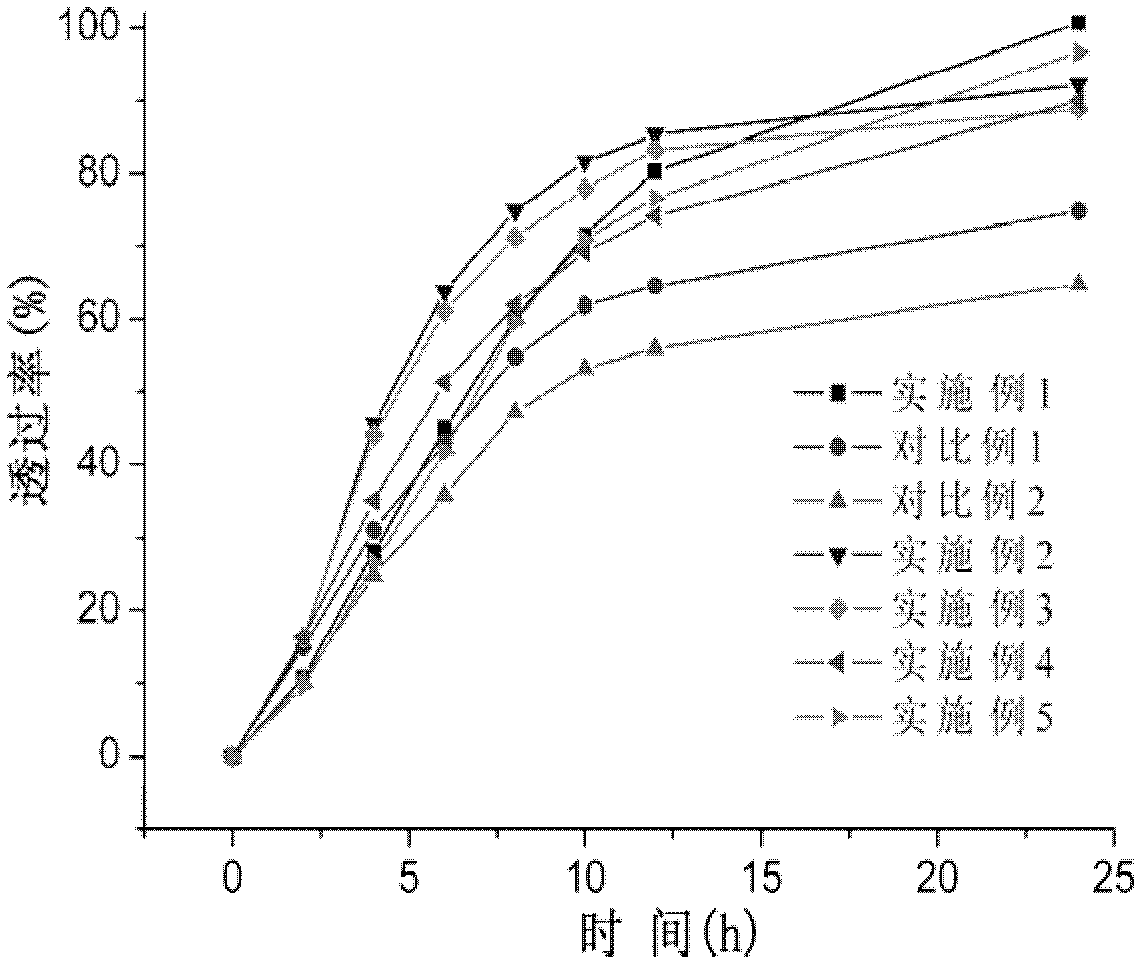

Embodiment 2

[0038]In the two-layer coating method, the volume ratio of the drug-containing colloid coated by the inner layer (close to the backing) and the outer layer (close to the cover film) is changed to 1: 3 to prepare a patch (the total drug-containing colloid amount of the coating is simultaneously an example 1), all the other are prepared according to the method in Example 1. The drug content of the obtained tulobuterol sustained-release patch is 1mg / 5.06cm 2 .

Embodiment 3

[0040] In the two-layer coating method, the volume ratio of the drug-containing colloid coated by the inner layer (close to the backing) and the outer layer (close to the cover film) is changed to 3: 1 to prepare a patch (the total drug-containing colloid amount of the coating is simultaneously an example 1), all the other are prepared according to the method in Example 1. The drug content of the obtained tulobuterol sustained-release patch is 1mg / 5.06cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com