Copper metal fiber with regular flaky finned structure and manufacturing method for same

A manufacturing method and copper metal technology, applied in the field of metal fiber manufacturing, can solve the problems of difficulty in meeting the mass production of metal fibers, high production cost, low bonding strength, etc., and achieve rich surface structure and morphology, efficient manufacturing process, The effect of improving sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

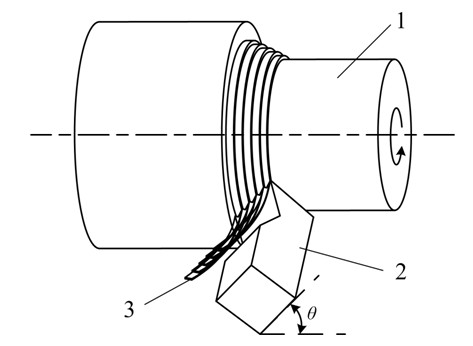

[0025] Such as figure 1 Shown is the schematic diagram of the principle of the cutting process of the present invention. A high beryllium copper round rod is selected as the raw material. First, the surface of the workpiece 1 is cleaned and degreased, and the oxide layer on the surface of the workpiece 1 is removed by using the cylindrical turning method, and then one end of the workpiece 1 is fixed. On the three-jaw chuck of the CA6140 lathe, use a tapered drill bit with a diameter of 10 mm to cut a tapered hole with a depth of about 8 mm at the center of the other end surface of the workpiece 1 . Replace the tapered drill bit with a tapered thimble, and press the tapered hole so that the workpiece 1 can rotate smoothly to reduce the impact of vibration;

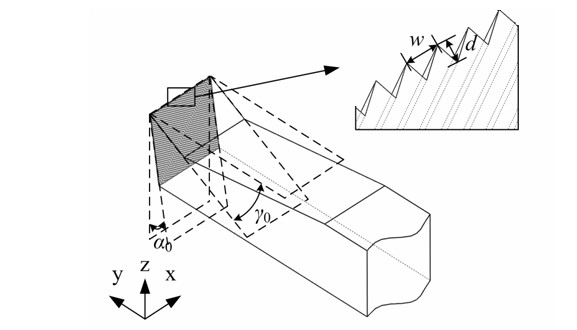

[0026] Such as figure 2 It is a schematic diagram of the geometric structure of the multi-tooth tool 2. The multi-tooth tool is a multi-tooth tool with a large edge angle. The multi-tooth tool 2 is installed on the lathe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com