Self-assembly controllable preparation method of composite of metal nano particles and carbon materials

A technology of metal nanoparticles and metal particles, which is applied in the field of nanomaterials, can solve the problems of difficult combination of particle size and activity, high preparation cost, difficult removal of impurities, etc., and achieve good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0031] A self-assembled and controllable preparation method for metal nanoparticles and carbon material composites, comprising the following steps:

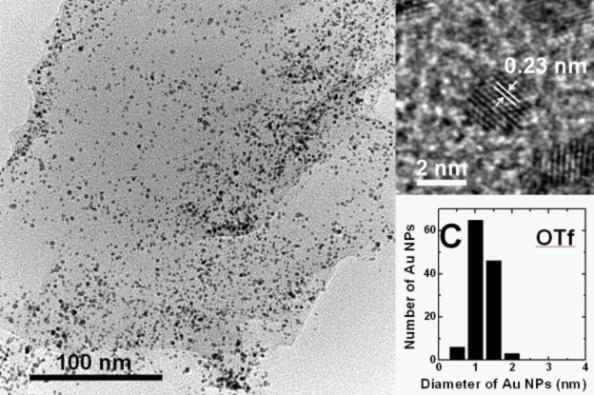

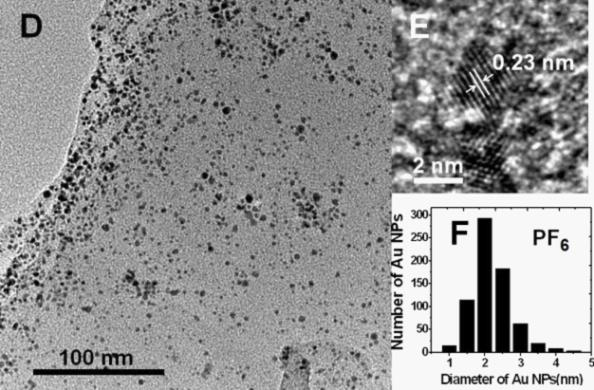

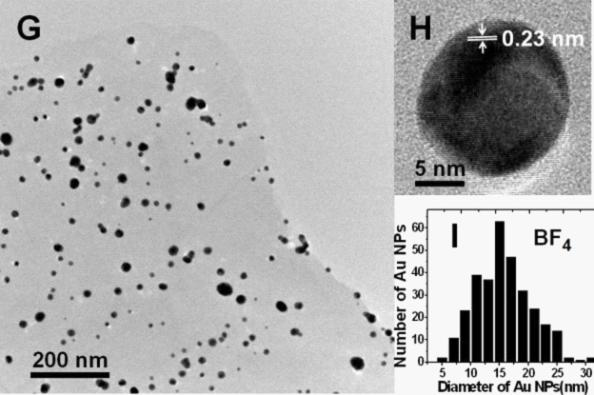

[0032] First, the carbon material carrier is fully dispersed into the ionic liquid solution by ultrasound to obtain the suspension of the ionic liquid; then the suspension is transferred to the container, and various kinds of For different metal targets, a mixed solution of ionic liquid-carbon material-metal particles is obtained at this time; finally, the ionic liquid is washed by high-speed centrifugation and organic solvents such as acetone or absolute ethanol, and the metal particles formed by self-assembly can be obtained. Nanocomposites of particle-carbon material supports.

[0033] Further, the carbon material carrier is one of graphene oxide, reduced graphene oxide, graphene, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com