Double-surface polishing method for gallium antimonide wafer

A double-sided polishing, gallium antimonide technology, applied in surface polishing machine tools, grinding/polishing equipment, electrical components, etc., can solve the problems of reducing MESFET structure, reducing material resistivity uniformity and electron mobility, etc. Strong operability, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

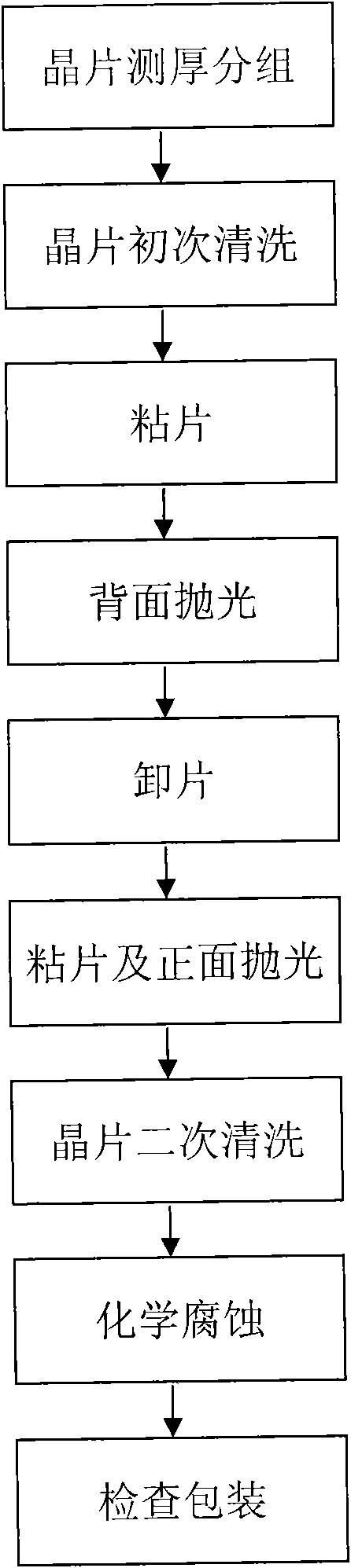

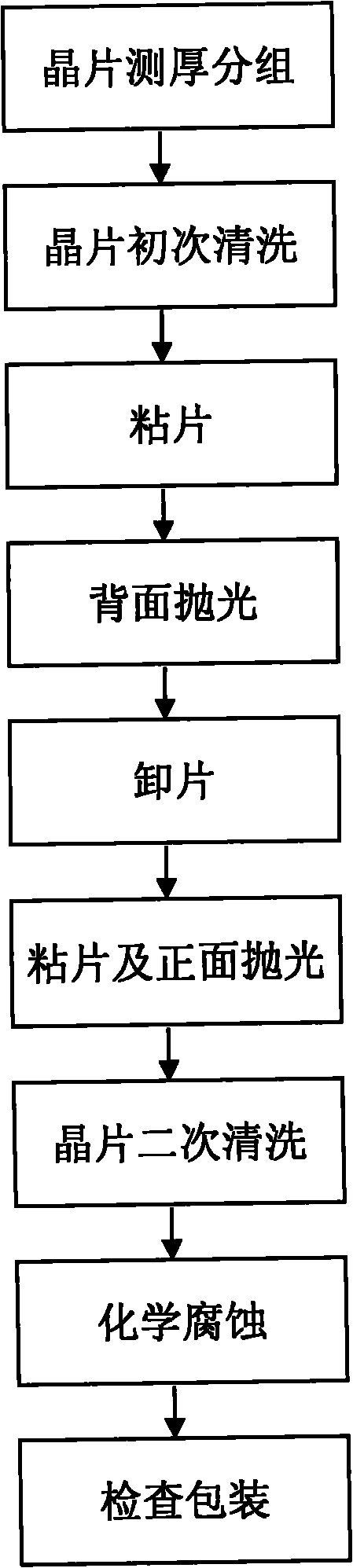

Method used

Image

Examples

Embodiment 1

[0028] 1. Wafer thickness measurement grouping: Qualified wafers are divided into grading lines with a thickness difference of 5 μm.

[0029] 2. Initial wafer cleaning: use pure water, H 2 o 2 and NH 4 OH was prepared into an etching solution with a volume ratio of 10:2:1, heated to 30°C, and the wafer was etched in the etching solution for 40 seconds. Rinse with pure water after corrosion, and then dry the water with filter paper.

[0030] 3. Bonding: Carry out front bonding when the surface temperature of the polishing disc is 30°C.

[0031] 4. Backside polishing: use pure water, polishing agent and sodium hypochlorite to prepare a polishing solution at a volume ratio of 90:4:2, set the temperature of the polishing solution at 20°C, set the polishing pressure at 15psi, and the polishing time for 20 minutes. The liquid flow rate was 70 ml / min for backside polishing.

[0032] 5. Unloading: heat the polishing disc to melt the wax layer around the wafer for unloading.

[0...

Embodiment 2

[0038] 1. Wafer thickness measurement and grouping: the qualified wafers are divided into grading lines with a thickness difference of 5-10 μm.

[0039] 2. Initial wafer cleaning: use pure water, H 2 o 2 and NH 4 OH was prepared into an etching solution with a volume ratio of 20:1:5, heated to 40°C, and the wafer was etched in the etching solution for 30 seconds. Rinse with pure water after corrosion, and then dry the water with filter paper.

[0040] 3. Bonding: Carry out front bonding when the surface temperature of the polishing disc is 40°C.

[0041] 4. Back polishing: use pure water, polishing agent and sodium hypochlorite to prepare a polishing liquid in a volume ratio of 70:5:5, set the temperature of the polishing liquid at 45°C, set the polishing pressure at 5 psi, and the polishing time for 30 minutes. The liquid flow rate was 50 ml / min for backside polishing.

[0042] 5. Unloading: Heat the polishing disc to melt the wax layer at the bottom of the wafer for unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com