ZSM-11 molecular sieve with hierarchical porous structure and preparation method thereof

A ZSM-11, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problem that nano molecular sieve cannot achieve industrial application value, nano molecular sieve grain size is reduced, Problems such as poor thermal and hydrothermal stability, achieving good thermal and hydrothermal stability, reducing benzene content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Under stirring conditions, prepare the following two working solutions respectively:

[0045] Mixture I: 15g of silica sol (40% SiO 2 , 60%H 2 O, hereinafter the same), 0.97g tetrabutylammonium bromide (99%), 11.3g deionized add in the beaker and mix homogeneously;

[0046] Mixture II: a homogeneous solution prepared from 1.33g of aluminum sulfate, 1.50g of sodium hydroxide and 15g of deionized water;

[0047] Under constant stirring, slowly add mixture II to mixture I, continue to stir until uniform, and the mass ratio of the obtained reaction mixture is Na 2 O:Al 2 o 3 : SiO 2 :(TBA) 2 O:H 2 O=9.0:1.0:50:0.75:1000, transfer the obtained initial gel to a reaction kettle with a polytetrafluoroethylene lining, seal it and place it in a hydrothermal synthesis oven, and keep the temperature at 90°C for 24h, Then the temperature was raised to 150°C and the temperature was maintained for 24h. After the reaction kettle was cooled, the solid was separated from the mot...

Embodiment 2

[0050] Under stirring conditions, prepare the following two working solutions respectively:

[0051] Solution I: Add 15g silica sol, 3.23g tetrabutylammonium bromide, and 40.2g deionized into a beaker and mix well.

[0052] Solution II: a homogeneous solution prepared by 1.33g aluminum sulfate, 2.00g sodium hydroxide and 40g deionized water

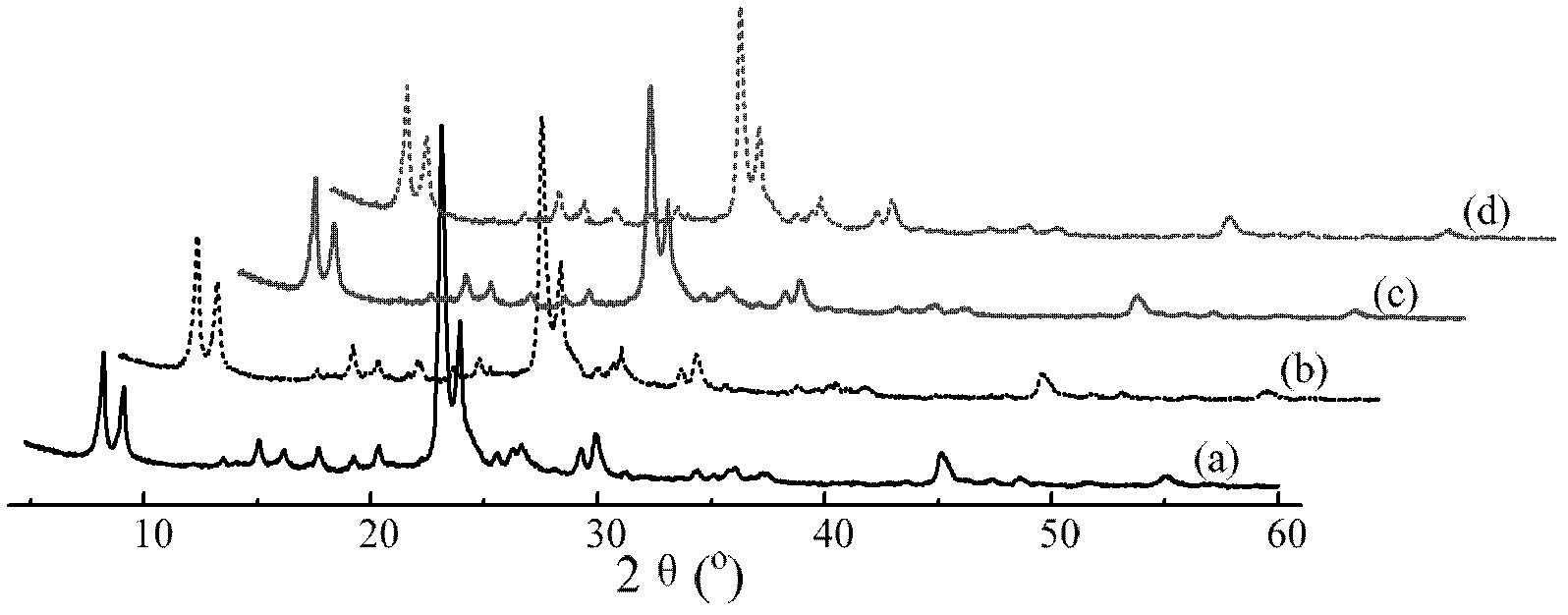

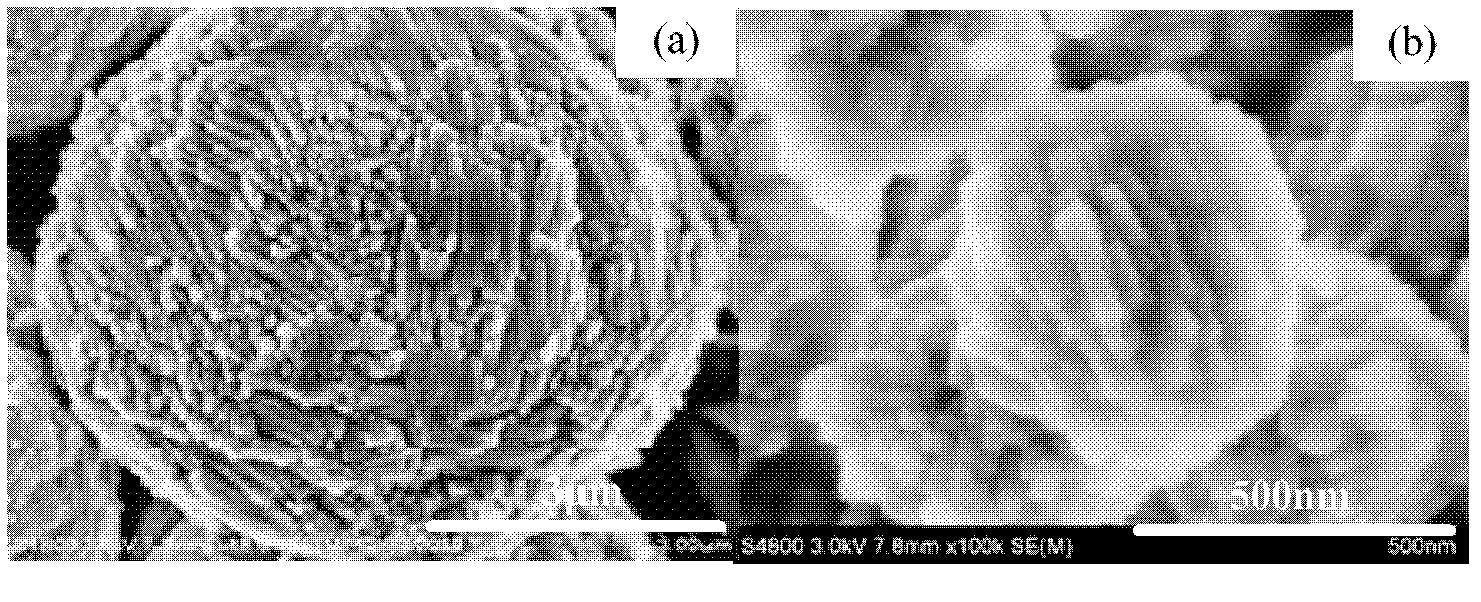

[0053] Under continuous stirring, slowly add solution II to solution I, and continue stirring until uniform. The molar ratio of the initial gel is Na 2 O:Al 2 o 3 : SiO 2 :(TBA) 2 O:H 2 O=12.0:1.0:50:2.5:2500. The crystallization conditions are the same as in Example 1. The final product powder is analyzed by X-ray diffraction, and the result is the same as figure 1 (a) are basically consistent, and its morphology measured by scanning electron microscopy is consistent with that of figure 2 (a) match.

Embodiment 3

[0055] The raw materials, composition and process flow of this example are the same as in Example 1, the difference is: after the raw materials are mixed evenly, they are transferred to a reaction kettle with a polytetrafluoroethylene lining, and after sealing, the temperature is kept at 90°C for 384h, and then the temperature is raised Continue constant temperature to 180°C for 8h. The product is ZSM-11 molecular sieve with a crystallinity of 98.39% and a particle size of 1.5 μm. The final product powder is analyzed by X-ray diffraction, and the result is the same as figure 1 (a) are basically consistent, and its morphology measured by scanning electron microscopy is consistent with that of figure 2 (a) match.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com