Method for preparing aluminum oxide-based eutectic ceramic through laser powder feeding method

A technology of eutectic ceramics and alumina, which is applied in the field of laser rapid prototyping preparation of high-performance materials, can solve the problems of rare preparation technology and limited laser processing and forming technology, so as to facilitate the study of solidification theory, improve quality and performance, The effect of eliminating pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

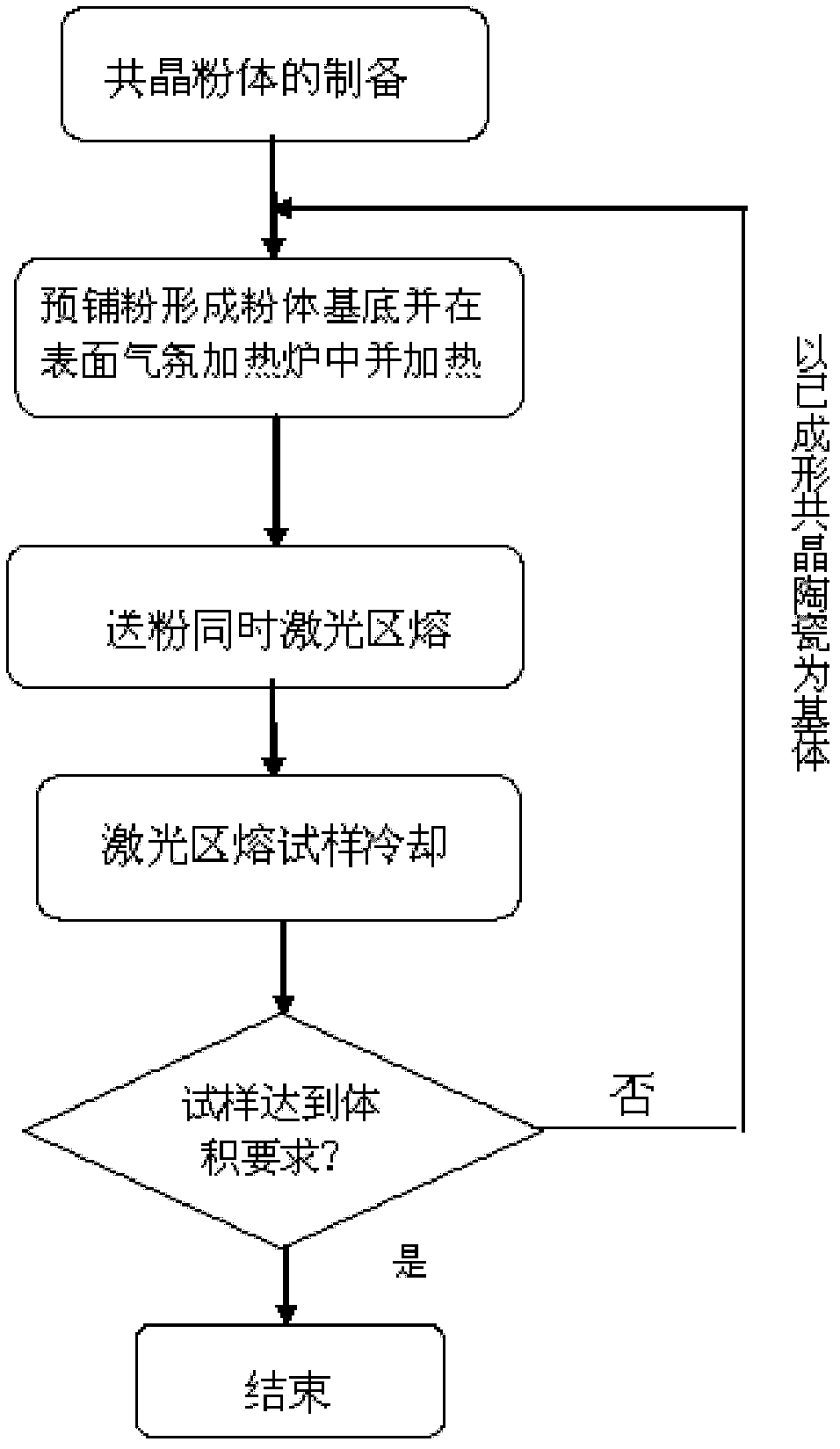

Method used

Image

Examples

Embodiment 1

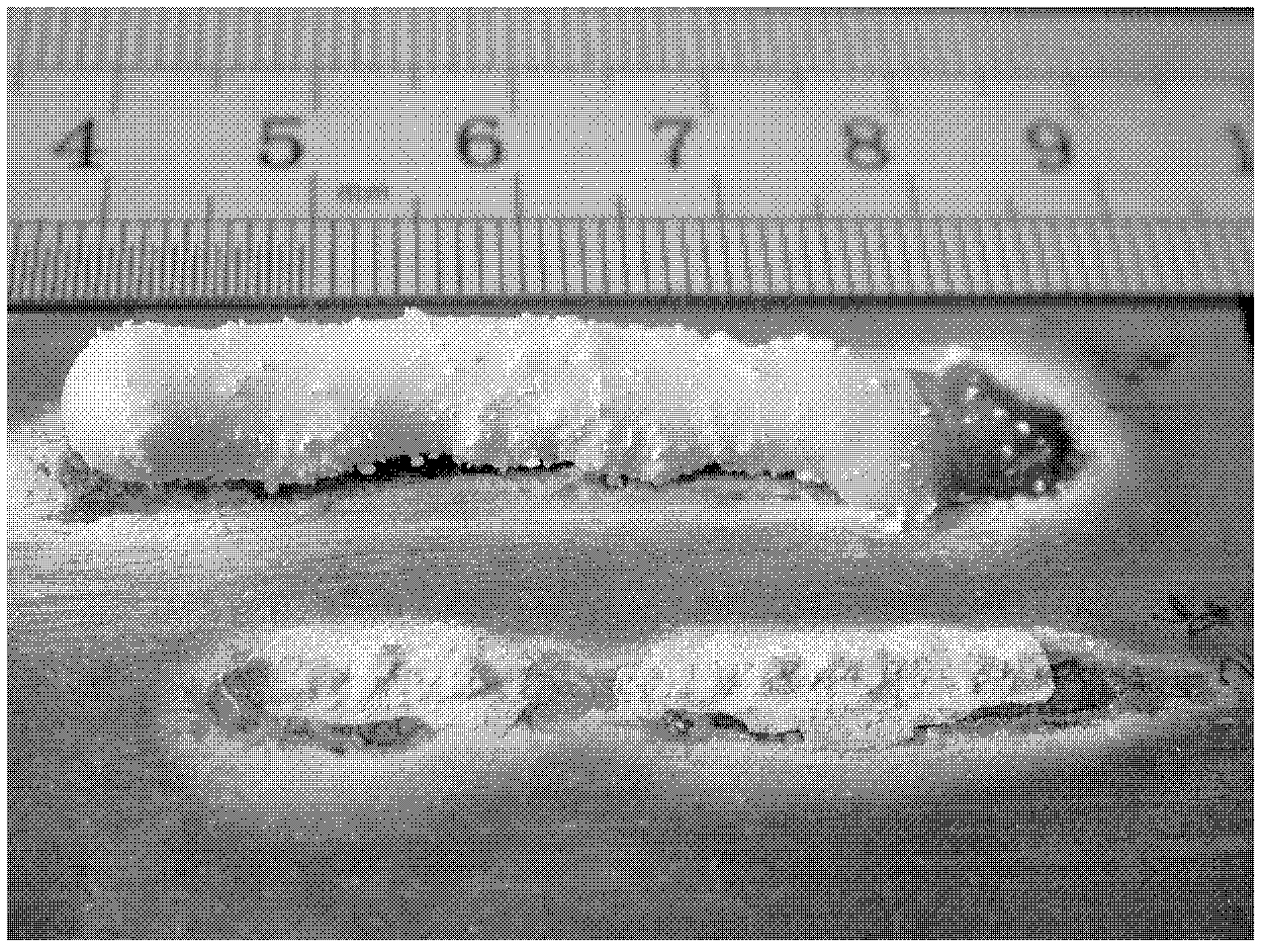

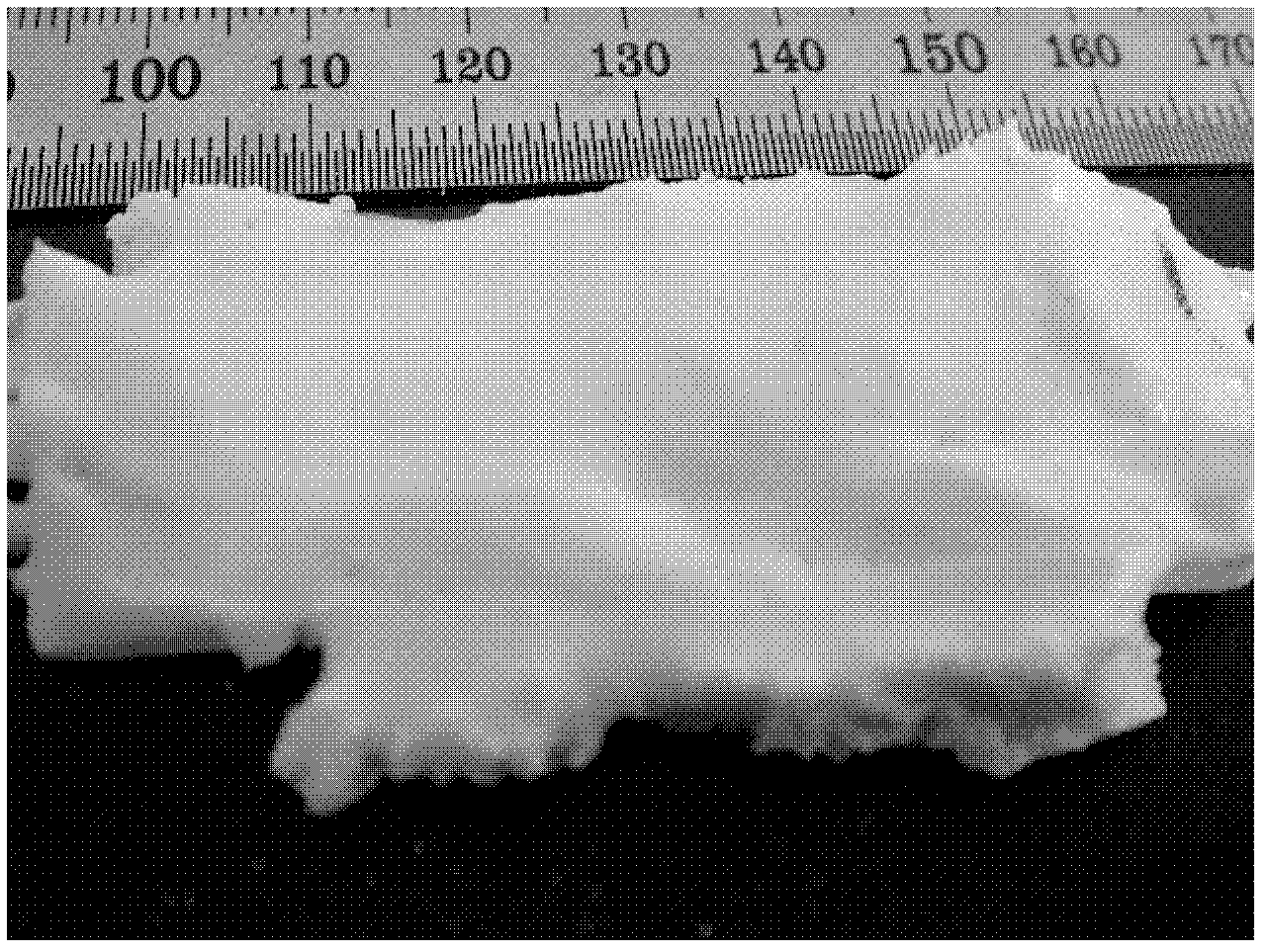

[0026] This embodiment is a method for preparing alumina-based eutectic ceramics by powder feeding method. This embodiment adopts this method to prepare Al 2 o 3 / YAG eutectic ceramics, the specific process includes the following steps:

[0027] Step 1, prepare Al 2 o 3 / YAG eutectic ceramic powder. with high purity Al 2 o 3 , Y 2 o 3 Powder as raw material, according to eutectic mole percentage Al 2 o 3 : Y 2 o 3 =81:19 Ratio weighing raw materials, adding PVA binder in the weighed raw materials; the added PVA binder is 10% of the total amount of raw materials. The above-mentioned configured raw materials were placed in a PMQW type omnidirectional planetary ball mill and mixed for 4 hours. The speed of the ball mill is 100r / min. Mix the powder evenly to get the prepared Al 2 o 3 / YAG eutectic ceramic powder.

[0028] Step 2, heating in a surface atmosphere heating furnace. Spread the obtained part of the powder evenly on the metal substrate to form Al 2 o ...

Embodiment 2

[0032] This embodiment is a method for preparing alumina-based eutectic ceramics by powder feeding method. This embodiment adopts this method to prepare ternary eutectic ceramics, and its specific process includes the following steps:

[0033] Step 1, prepare Al 2 o 3 / YAG / YSZ eutectic ceramic powder. with high purity Al 2 o 3 , Y 2 o 3 , ZrO 2 Powder as raw material, according to eutectic mole percentage Al 2 o 3 : Y 2 o 3 : ZrO 2 =65.8: 15.6: 18.6 Ratio Weigh raw materials, add PVA binding agent in the weighed raw materials; The added PVA binding agent is 10% of raw material total amount. The above-mentioned configured raw materials were placed in a PMQW type omnidirectional planetary ball mill and mixed for 4 hours. The speed of the ball mill is 100r / min. Mix the powder evenly to get the prepared Al 2 o 3 / YAG / YSZ eutectic ceramic powder.

[0034] Step 2, heating in a surface atmosphere heating furnace. Spread the obtained part of the powder evenly on the ...

Embodiment 3

[0038] This embodiment is a method for preparing alumina-based eutectic ceramics by powder feeding method. This embodiment adopts this method to prepare Al 2 o 3 / GdAlO 3 (GAP) eutectic ceramics, the specific process includes the following steps:

[0039] Step 1, prepare Al 2 o 3 / GAP eutectic ceramic powder. with high purity Al 2 o 3 、Gd 2 o 3 Powder as raw material, according to eutectic mole percentage Al 2 o 3 :Gd 2 o 3 The ratio of =77:23 weighs the raw materials, and adds PVA binder in the weighed raw materials; the added PVA binder is 10% of the total amount of raw materials. The above-mentioned configured raw materials were placed in a PMQW type omnidirectional planetary ball mill and mixed for 4 hours. The speed of the ball mill is 100r / min. Mix the powder evenly to get the prepared Al 2 o 3 / GAP eutectic ceramic powder.

[0040] Step 2, heating in a surface atmosphere heating furnace. Spread the obtained part of the powder evenly on the metal subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com