Stainless steel and zirconium oxide ceramic compound part and manufacturing method thereof

A technology of zirconia ceramics and manufacturing methods, which is applied in the direction of chemical instruments and methods, ceramic layered products, coatings, etc., and can solve the problems of reducing thermal stress, poor bonding force, and limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

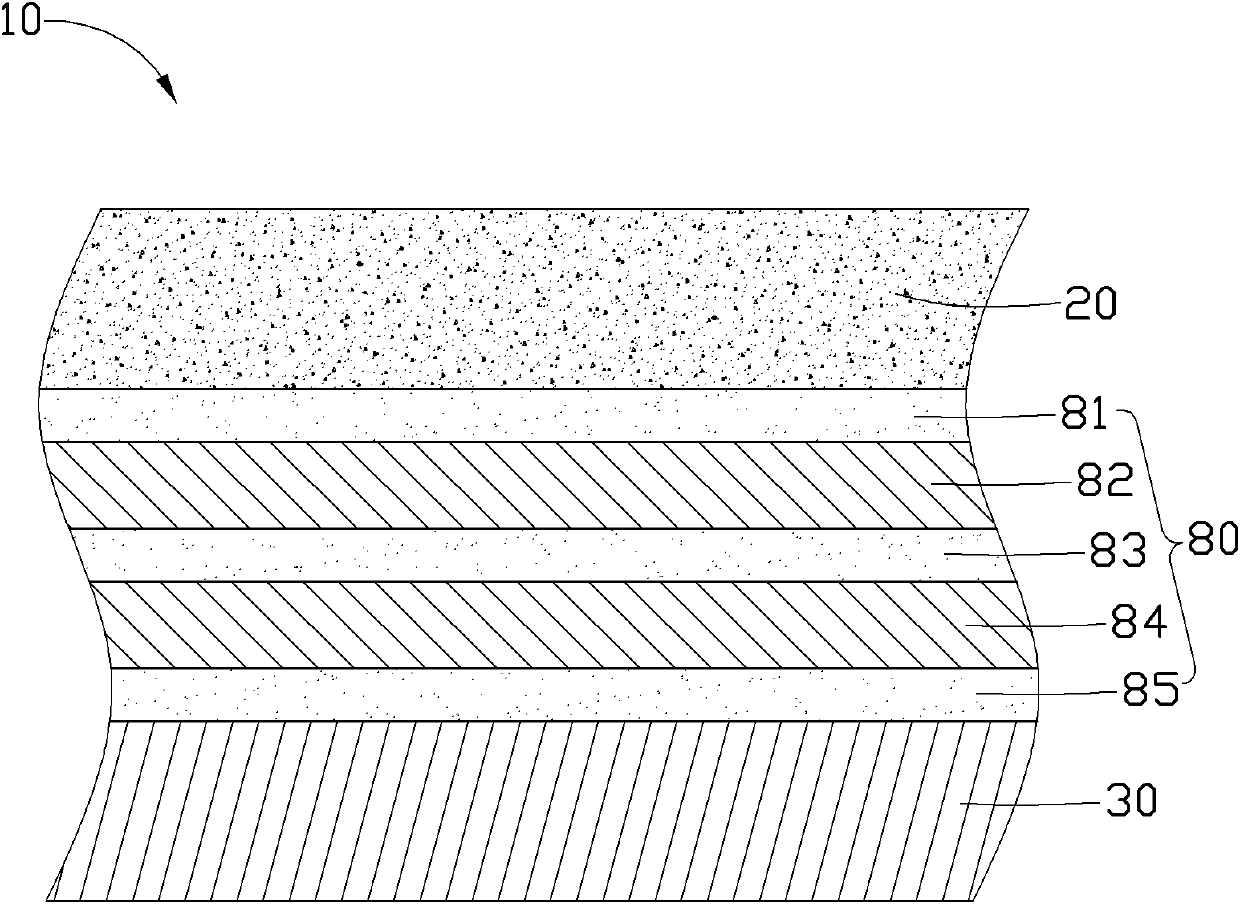

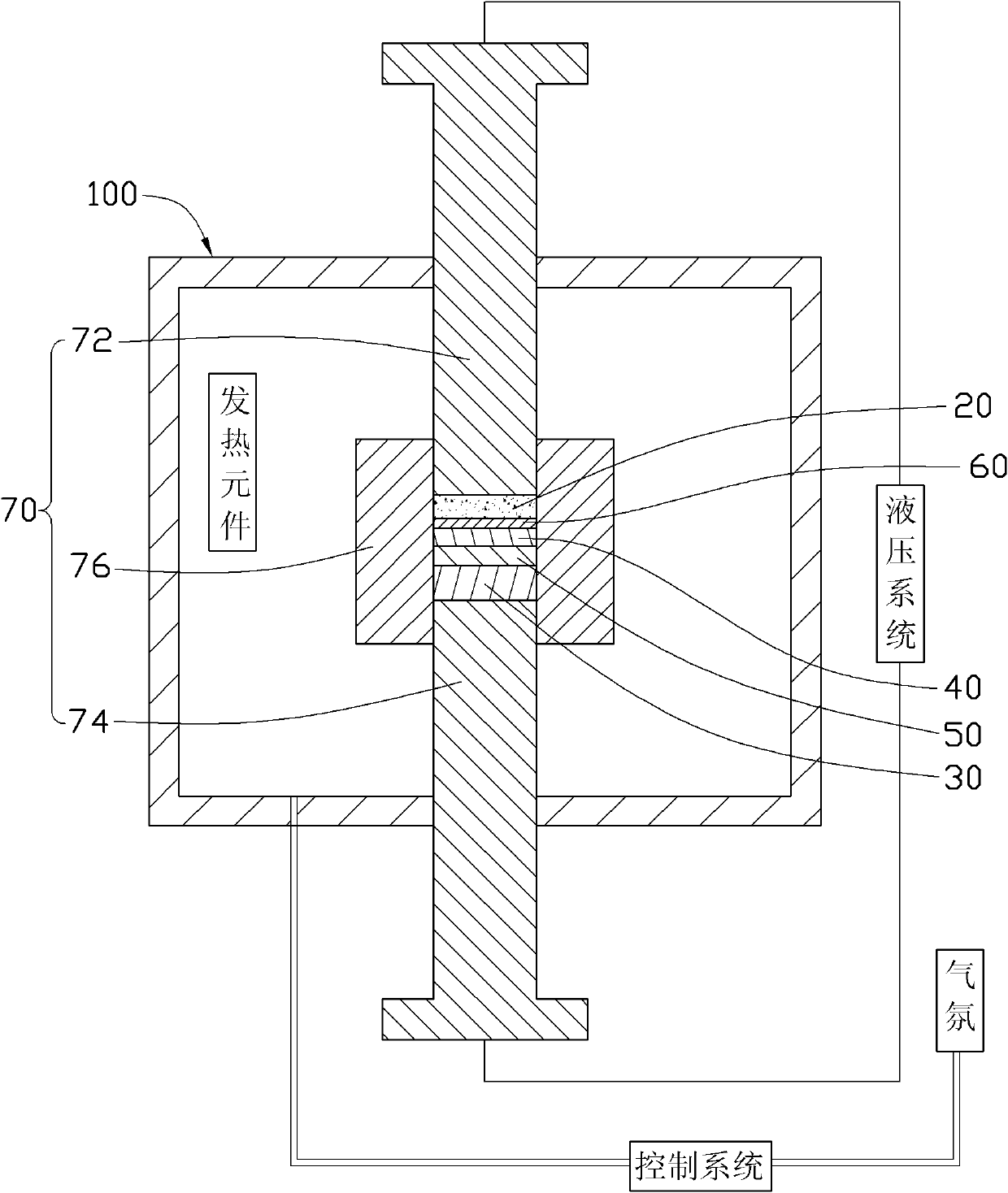

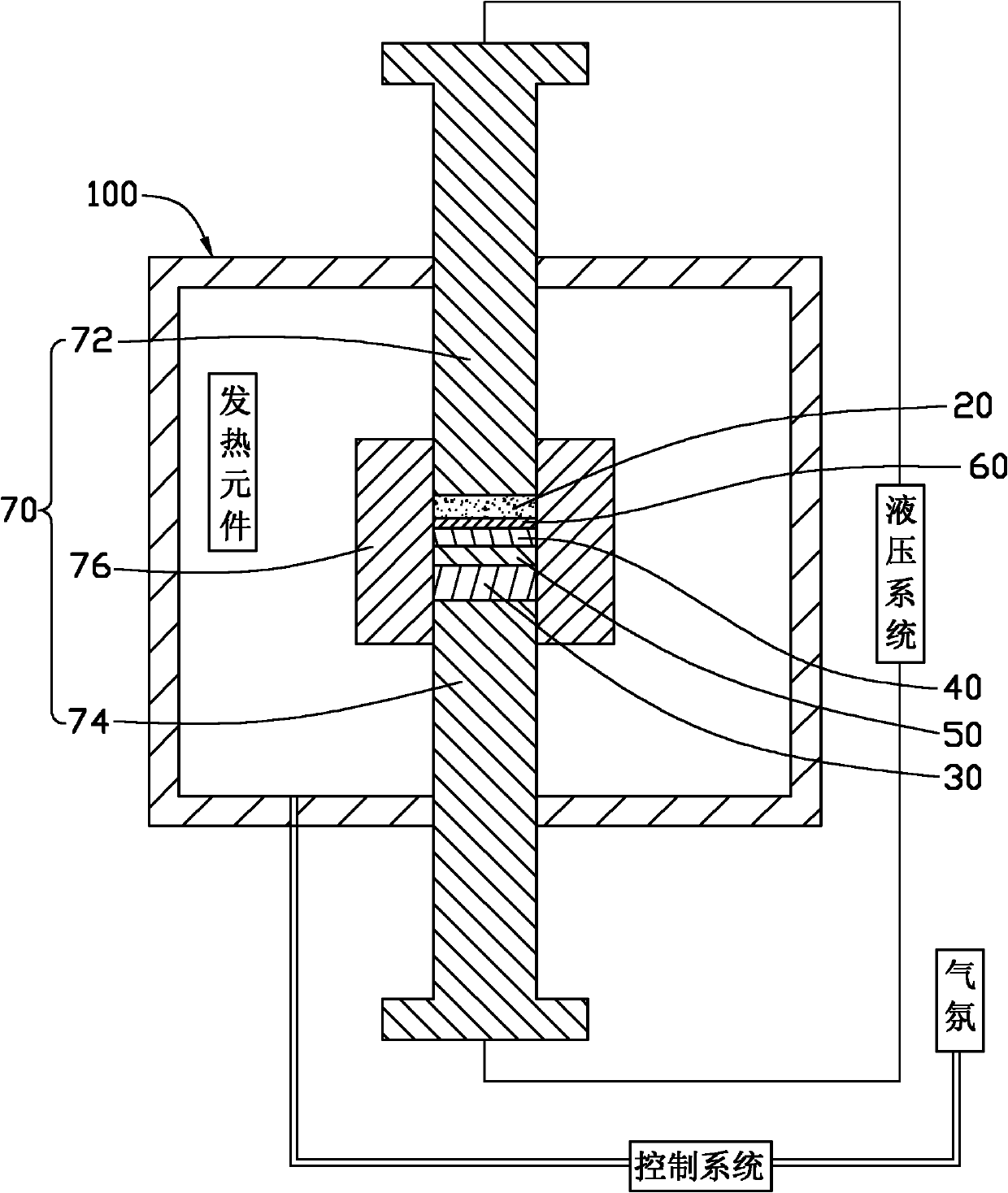

[0034] figure 1 Shown is a stainless steel and zirconia ceramic composite part 10, including the zirconia ceramic part 20, the stainless steel part 30, and a connection layer 80 connecting the stainless steel part 30 and the zirconia ceramic part 20, in the manufacture of stainless steel and zirconia ceramic composite The part 10 also needs to deposit a nickel metal layer 60 on the surface of the zirconia ceramic part 20 . The connection layer 80 includes a first transition layer 81 , a molybdenum layer 82 , a second transition layer 83 , a nickel layer 84 and a third transition layer 85 .

[0035] The first transition layer 81 is located between the zirconia ceramic part 20 and the molybdenum layer 82 . The first transition layer 81 is mainly composed of nickel-molybdenum intermetallic compound, zirconium-nickel intermetallic compound, nickel-molybdenum solid solution, zirconium-nickel solid solution, and also includes a small amount of zirconium-molybdenum intermetallic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com