Method for manufacturing water permeable brick by using sugar filter mud

A technology of sugar filter mud and permeable bricks, which is applied in the fields of sewage treatment, resources and environment, and achieves the effects of low production cost, good water permeability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

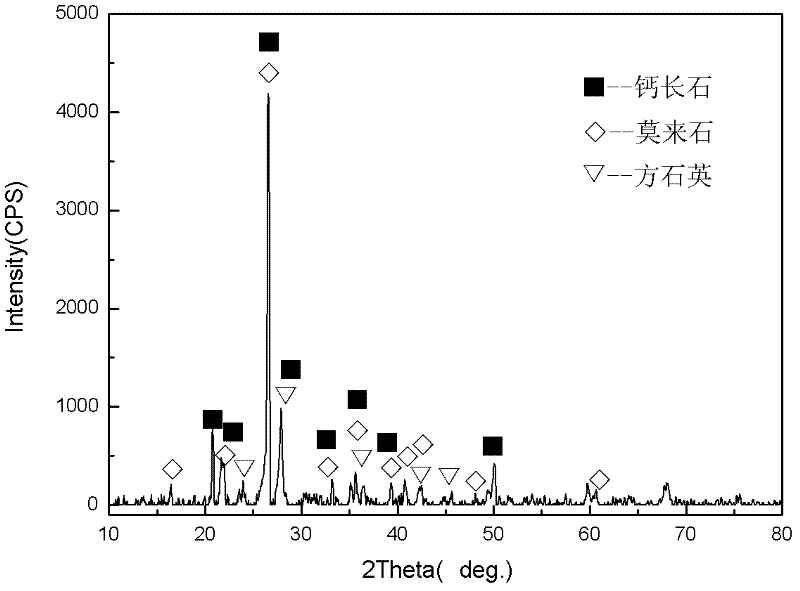

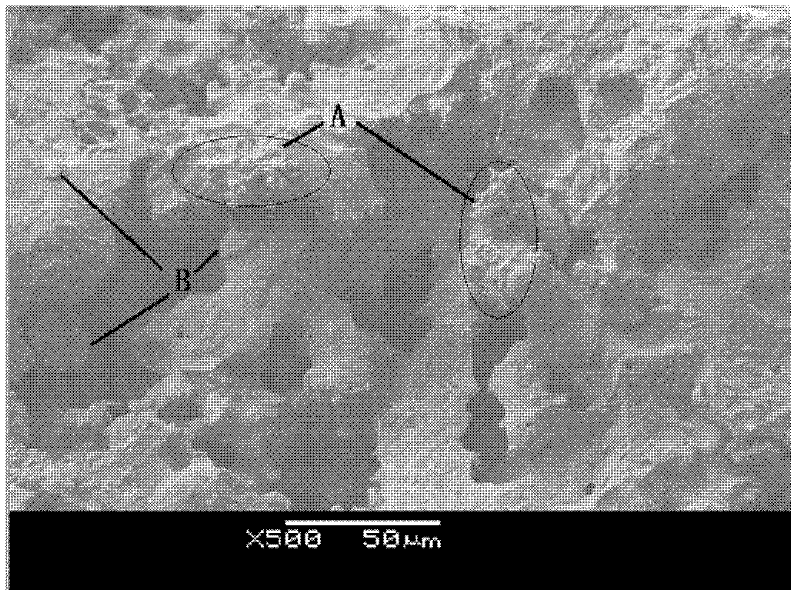

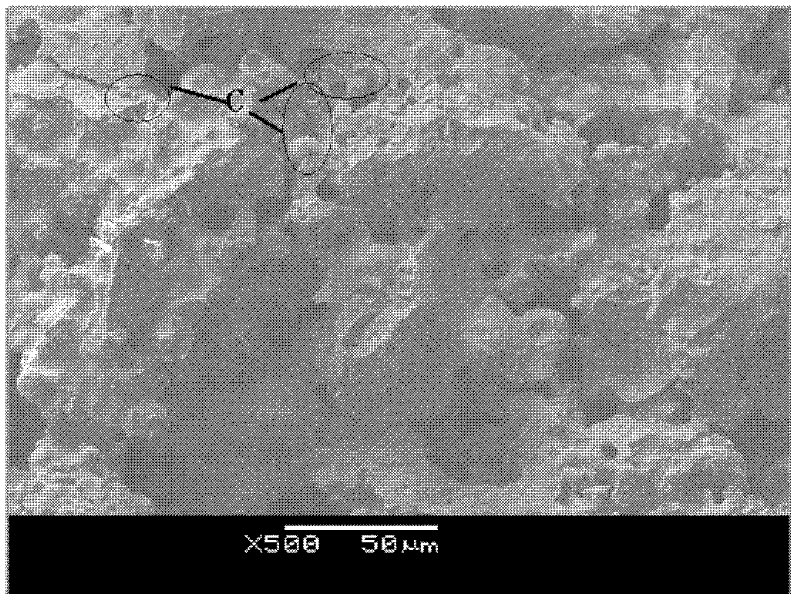

Image

Examples

Embodiment 1

[0021] a. Raw material preparation: Naturally dry the sugar beet sugar filter sludge obtained by the carbonation method to make the relative moisture content ≤ 13%; crush the obtained sugar filter sludge and pass through a 100-mesh sieve; crush waste ceramics to a particle size of 0.85-2.00 mm; pulverize coal Ash and clay are passed through a 160-mesh sieve.

[0022] b. Blank making: according to the mass percentage of the permeable brick formula: 22% of pore-forming agent sugar filter mud, 25% of fly ash, 30% of clay, and 23% of waste ceramics. Weigh various prepared raw materials and mix them with water. The required water is 10% of the absolute dry mass of the batch; stir for 3 hours to make it evenly mixed; put the stale material into the brick press for 48 hours after granulation, and the pressure is 20MPa; put the shaped bricks into In a drying oven, the drying temperature is 105° C., and the drying time is 6 hours to obtain a green body.

[0023] c. Sintering: Put the ...

Embodiment 2

[0026] a. material preparation: same as embodiment 1.

[0027] b. Billet making: according to the mass percentage of raw materials: 24% of pore-forming agent sugar filter mud, 25% of fly ash, 29% of clay, and 22% of waste ceramics. It is 12% of the absolute dry mass of the batching material; stir for 3 hours to make it evenly mixed; put the aged material into a brick press for 48 hours after granulation, and put the molded brick into a drying box , a drying temperature of 108° C. and a drying time of 6 hours to obtain a green body.

[0028] c. Sintering: Put the dried bricks into a box-type electric furnace, sinter them at 1100°C, keep them warm for 1 hour, and then they will become permeable bricks after cooling with the furnace.

Embodiment 3

[0030] a. material preparation: same as embodiment 1.

[0031] b. Blank making: according to the mass percentage of the permeable brick formula: 25% of pore-forming agent sugar filter mud, 25% of fly ash, 30% of clay, and 20% of waste ceramics. Weigh various prepared raw materials and mix them with water. The required moisture is 13% of the absolute dry mass of the batch; stir for 3 hours to make it evenly mixed; put the stale material into the brick press for 48 hours after granulation, and the pressure is 20MPa; put the formed brick into In a drying oven, the drying temperature is 108° C., and the drying time is 6 hours to obtain a green body.

[0032] c. Sintering: put the dried bricks into a box-type electric furnace, sinter them at 1110°C, keep them warm for 0.5h, and cool them down with the furnace to become permeable bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com