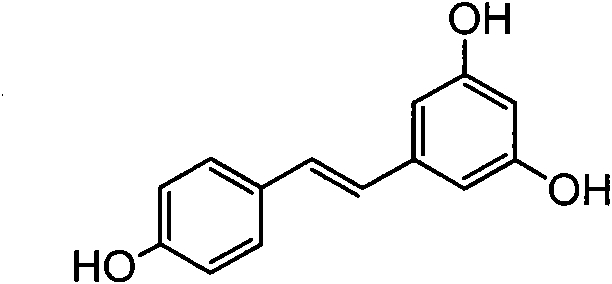

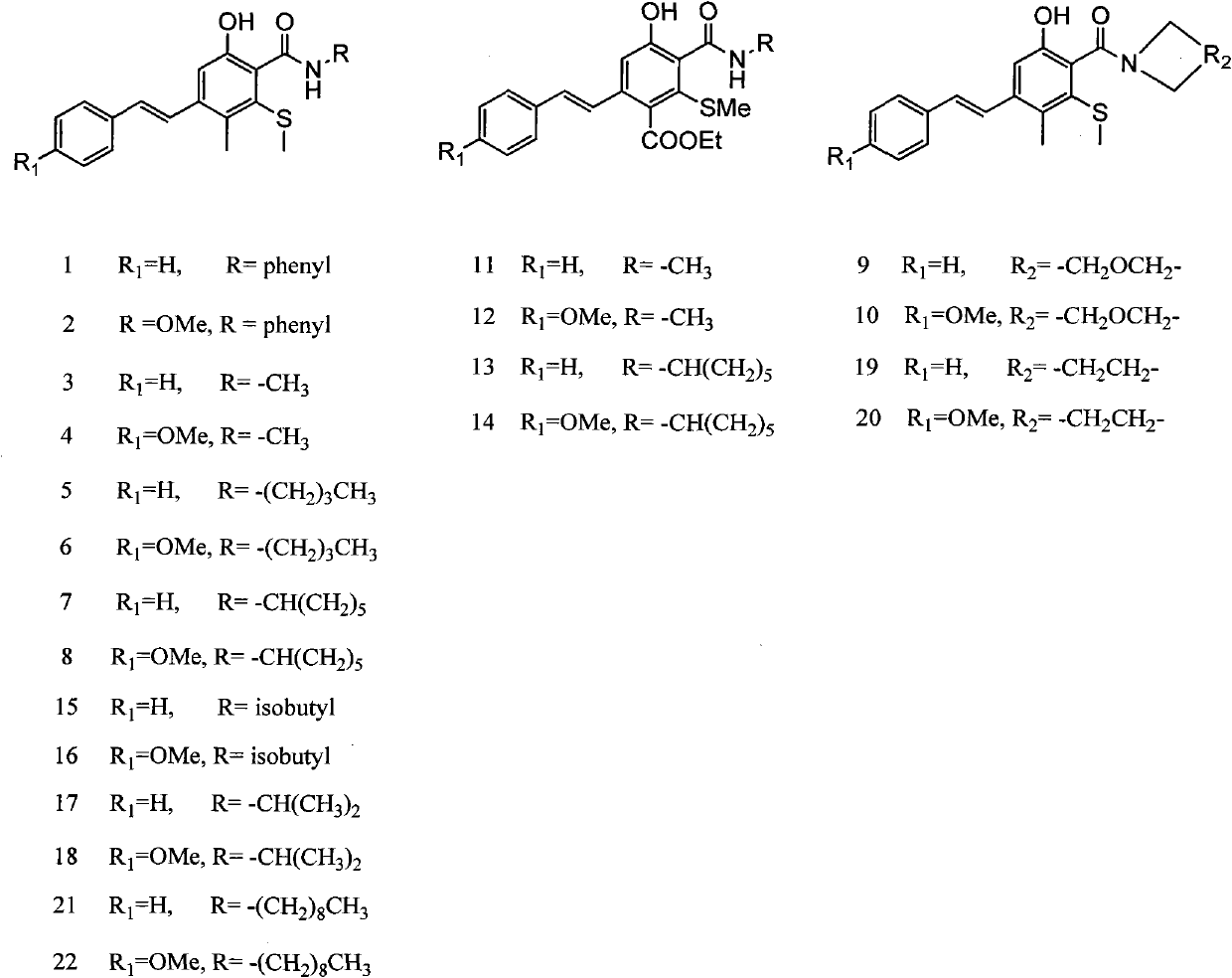

Method for synthesizing anti-form stilbene compounds and application of method in preparing anti-tumor medicines

A technology of stilbene compounds and anti-tumor drugs, which is applied in the field of synthesizing trans-stilbene compounds, can solve the problems of reduced yield, difficult separation, and difficulty in obtaining compounds, and achieves the effects of simple method, reduced cost, and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

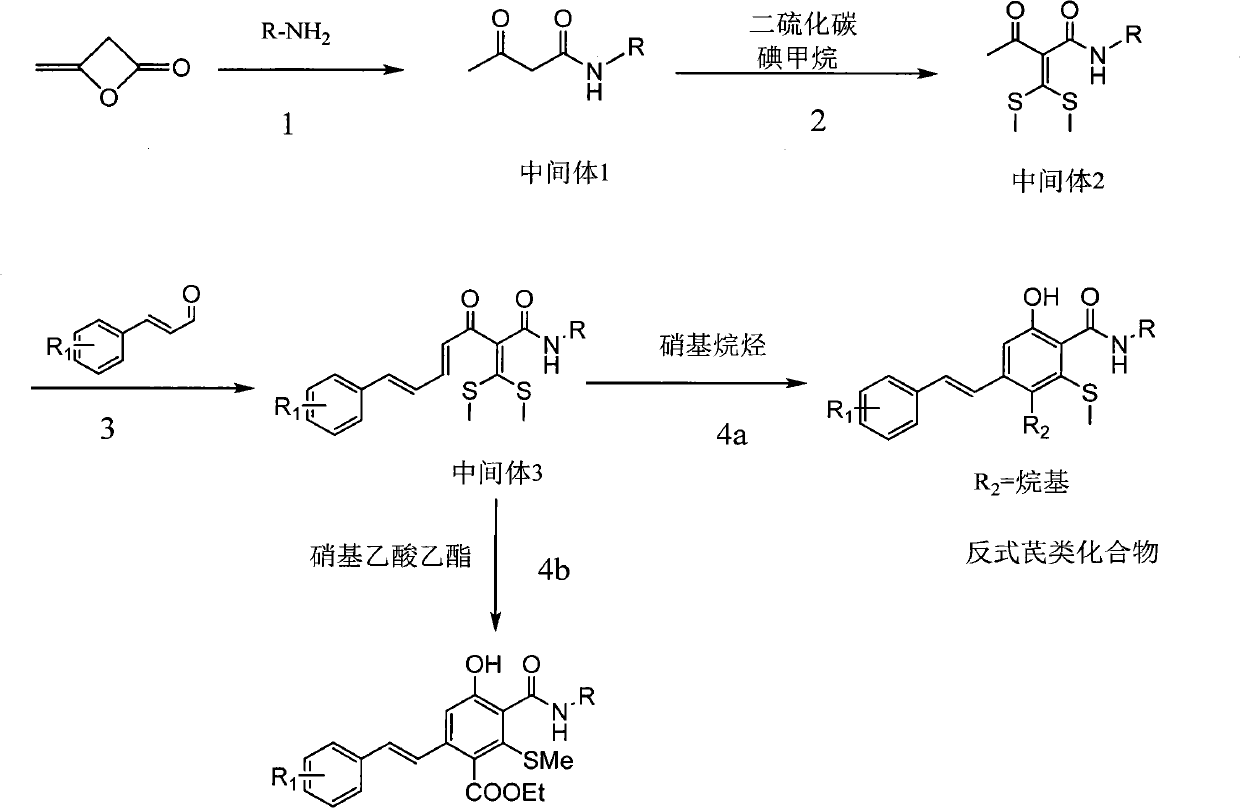

Method used

Image

Examples

Embodiment 1

[0033](1) Preparation of acetoacetylnonylamine: Dissolve 20mmol of nonylamine in 50ml of water, cool down to 0°C, add 20mmol of diketene dropwise within 1 hour, react for 2 hours after dropping, extract with dichloromethane, wash the organic layer with water, and dry , filtered with suction, concentrated to dryness under reduced pressure to obtain acetoacetylnonylamine with a yield of 96%;

[0034] (2) Preparation of 2-(bis(methylthio)methenyl)-N-nonyl-3-oxobutanamide: 20mmol of acetoacetylnonylamine obtained in the previous step was dissolved in 50ml of N,N-dimethyl In base formamide, cool down to 0°C, add 50mmol potassium carbonate, stir at 0°C for 30min, then add 24mmol carbon disulfide, react at 0°C for 1 hour, then add 40mmol methyl iodide dropwise within 30min, rise to React at 10-35°C for 4 hours, pour into water, a yellow solid precipitates out, filter with suction, wash with water, and dry to obtain 2-(di(methylthio)methenyl)-N-nonyl-3-oxobutyramide , yield 88%;

[...

Embodiment 2

[0038] (1) Preparation of acetoacetylnonylamine: Dissolve 20mmol of nonylamine in 50ml of benzene, cool to 0°C, add 20mmol of diketene dropwise within 1 hour, react for 2 hours after dropping, wash the organic layer with water, dry, and suction filter. Concentrated to dryness under reduced pressure to obtain acetoacetylnonylamine with a yield of 93%;

[0039] (2) Preparation of 2-(bis(methylthio)methenyl)-N-nonyl-3-oxobutanamide: 20mmol of acetoacetylnonylamine obtained in the previous step was dissolved in 50ml of N,N-dimethyl In base formamide, cool down to 0°C, add 50mmol potassium carbonate, stir at 0°C for 30min, then add 24mmol carbon disulfide, react at 0°C for 1 hour, then add 40mmol methyl iodide dropwise within 30min, rise to 10 React at ~35°C for 4 hours, pour into water, a yellow solid precipitates, filter with suction, wash with water, and dry to obtain 2-(di(methylthio)methenyl)-N-nonyl-3-oxobutyramide, Yield 88%;

[0040] (3) (4E,6E)-2-(di(methylthio)methenyl)...

Embodiment 3

[0043] (1) Preparation of acetoacetylmorpholine: Dissolve 20mmol morpholine in 50ml benzene, cool to 0°C, add 20mmol diketene dropwise within 1 hour, react for 2 hours after dropping, wash the organic layer with water, dry, and suction filter, Concentrated to dryness under reduced pressure to obtain acetylacetylmorpholine with a yield of 89%;

[0044] (2) Preparation of 2-(bis(methylthio)methenyl)-1-morpholinyl-1,3-butanedione: 20mmol of acetylacetylmorpholine obtained in the previous step was dissolved in 50ml N,N- In dimethylformamide, cool down to 0°C, add 50mmol potassium carbonate, stir at 0°C for 30min, then add 24mmol carbon disulfide, react at 0°C for 1 hour, then add 40mmol methyl iodide dropwise at about 30min, after the addition is complete Rise to 10-35°C for 4 hours, remove N,N-dimethylformamide, extract with dichloromethane, wash with water, dry, filter with suction, concentrate under reduced pressure to dryness, and obtain 2-(bis(methylthio)methylene Base)-1-mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com