Method of preparing telechelic polymer

A technology of telechelic polymer and macromolecular polymer, which is applied in the field of polymers to achieve significant social and economic benefits and potential application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a preparation method of a telechelic polymer, comprising the following steps: mixing a metal-organic compound with a macromolecular polymer containing a carbon-carbon double bond in the main chain, and obtaining a telechelic polymer after a chain scission reaction. The above preparation process As follows:

[0027]

[0028] The macromolecular polymer used in the present invention is compound 1, a class of macromolecules with carbon-carbon double bonds in the main chain. There is no requirement for molecular weight and molecular weight distribution, and the content of unsaturated carbon-carbon double bonds in the main chain can be 0.2%. ~50% (based on the number of carbon-carbon bonds in the main chain). Described macromolecule polymer is preferably polybutadiene, polyisoprene or the copolymer (styrene-butadiene rubber) of butadiene and styrene, the simultaneously cross-linked polybutadiene, polyisoprene and cross-linked Styrene-butadiene rubb...

Embodiment 1

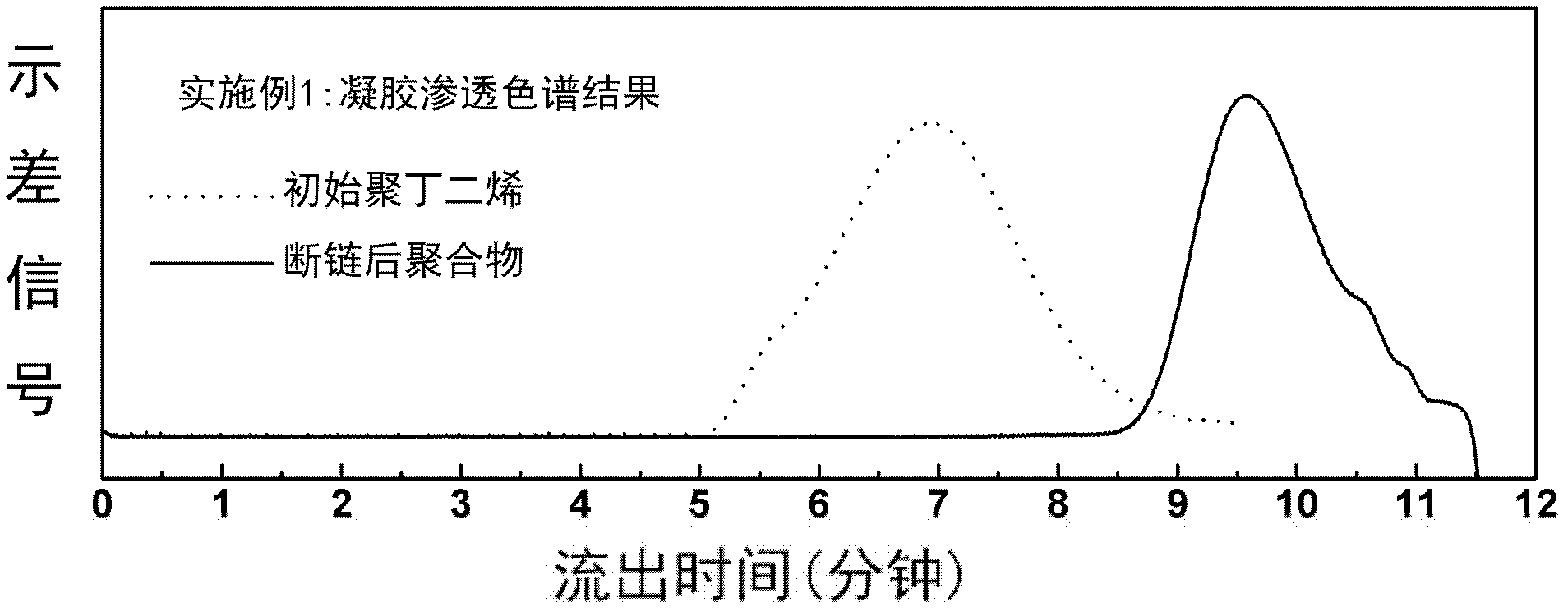

[0041] 100 parts by weight of linear polybutadiene (molecular weight is 200kDa), 30 parts by weight of dicyclopentadiene zirconium hydrochloride, mixed in tetrahydrofuran solution, stirred at room temperature for 30 minutes;

[0042] The telechelic polymer was obtained after precipitating with ethanol. Gel permeation chromatography test showed that all polybutadiene molecules were broken. The molecular weight of the obtained telechelic polymer was 2000 Da, and the molecular weight distribution index was 1.5.

[0043] The telechelic polymer prepared in the present embodiment was analyzed by gel permeation chromatography, and the results were as follows: figure 1 shown.

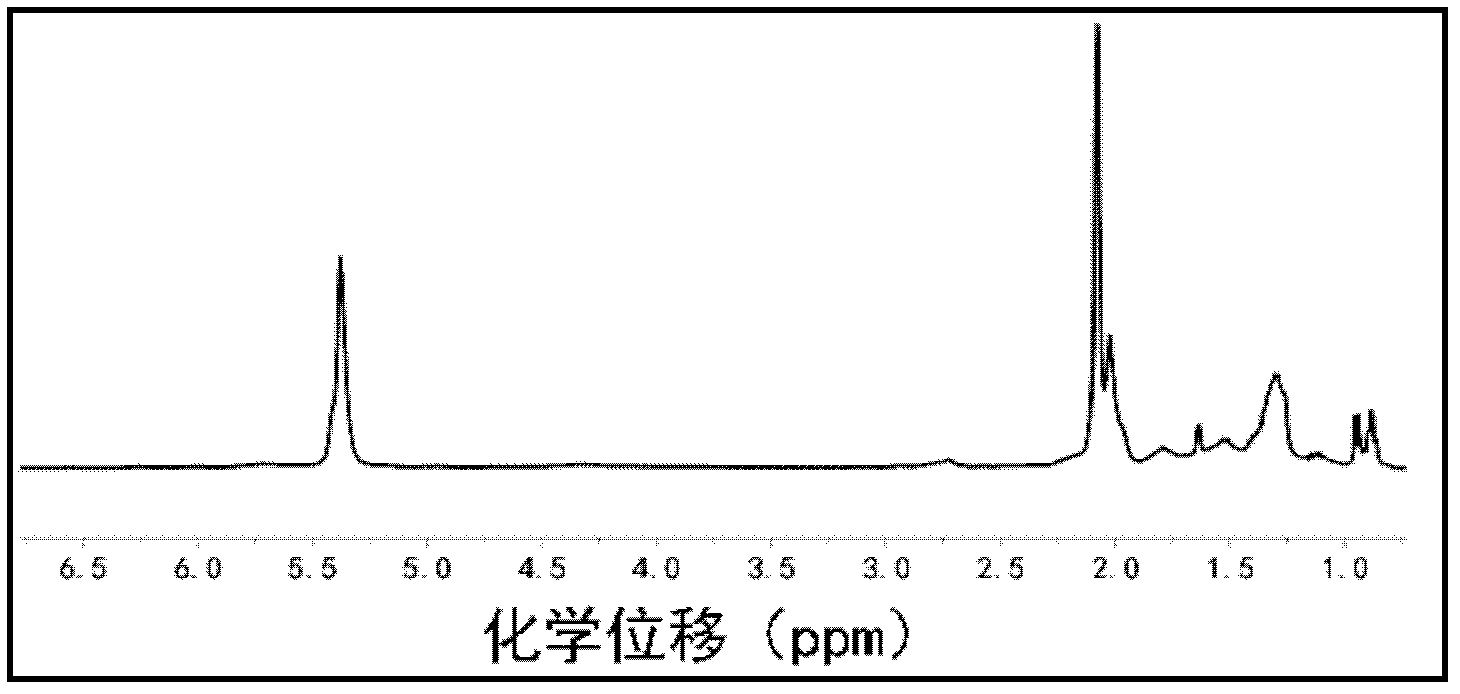

[0044] Carry out nuclear magnetic resonance analysis to the telechelic polymer prepared in this embodiment, figure 2 H NMR spectrum of the telechelic polymer prepared for this example.

[0045] The reaction raw materials used in this embodiment and the products generated are shown in Table 1.

Embodiment 2

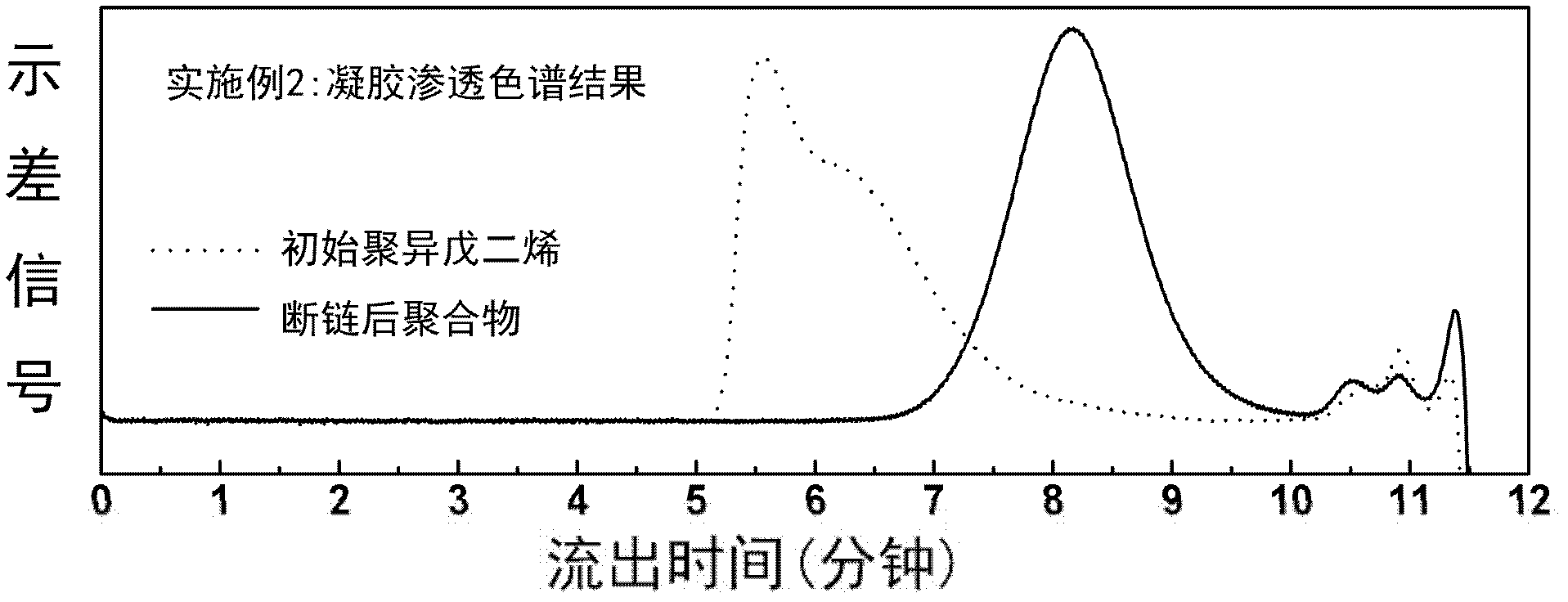

[0047] 100 parts by weight of linear polyisoprene (molecular weight is 660kDa), 30 parts by weight of dicyclopentadiene zirconium hydrochloride, mixed in tetrahydrofuran solution, stirred at room temperature for 10 hours;

[0048] The telechelic polymer was obtained after precipitation with ethanol, and gel permeation chromatography test showed that all polyisoprene chain scission occurred, the molecular weight of the obtained telechelic polymer was 10kDa, and the molecular weight distribution index was 2.

[0049] The telechelic polymer prepared in the present embodiment was analyzed by gel permeation chromatography, and the results were as follows: image 3 shown.

[0050] The reaction raw materials used in this embodiment and the products generated are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com