Synthetic method of solution polymerized butadiene-isoprene rubber

A technology of solution-polymerized butadiene-butadiene rubber and a polymerization method, which is applied in the field of polymerization of solution-polymerized butadiene-butadiene rubber, can solve the problems such as the inability to remove the structure regulator, the influence of the recovered solvent, and the coupling efficiency close to 0.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Cyclohexane / n-hexane mixed solvent (=82 / 18, weight ratio) system to synthesize star-shaped solution polybutadiene rubber (BD / IP=75 / 25, weight ratio)

[0039] The polymerization is carried out in a 5-liter stainless steel reactor. After the reactor is soaked with cyclohexane / n-hexane, it is evacuated and filled with nitrogen (high-purity nitrogen) for three times. The reactor is heated by hot oil and cooled by cold oil. The temperature of the hot oil is set to Set at 30°C, the cold oil temperature is set at 10°C. First, 2600 g of refined cyclohexane / n-hexane, 0.003 g of ETE, 291.38 g of butadiene, and 97.13 g of isoprene were added in one go. Then heat the reaction material with hot oil, and when the temperature in the reactor rises to 30°C, control the ratio of hot oil and cold oil to keep the temperature of the material stable, and then add 14ml (0.3M cyclohexane / n-hexane solution) to initiate polymerization. After 40 minutes of polymerization reaction, 0...

Embodiment 2-9

[0040] Example 2-9 Cyclohexane / n-hexane mixed solvent (=82 / 18, weight ratio) system to synthesize star-shaped solution polybutadiene rubber (BD / IP=75 / 25, weight ratio)

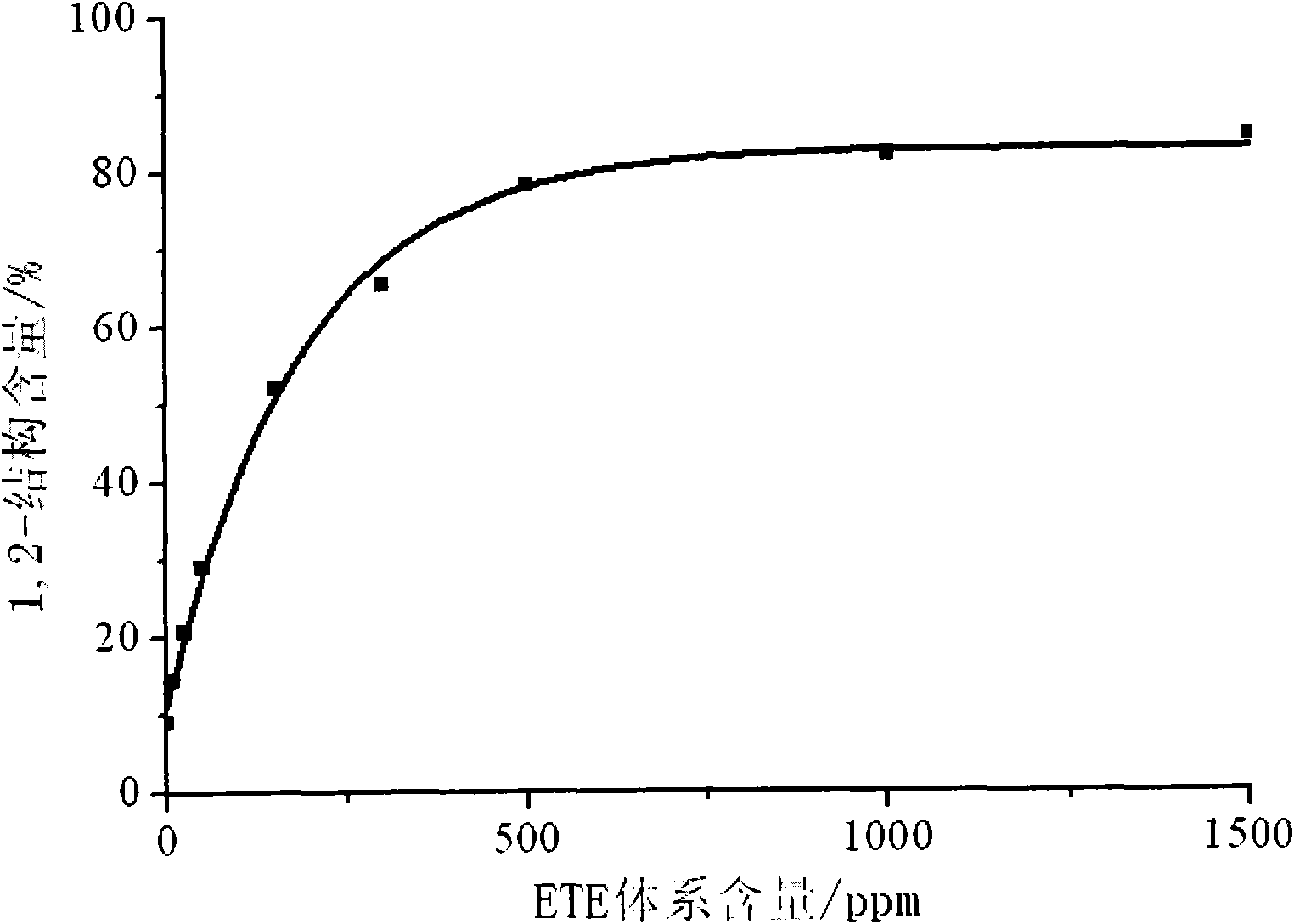

[0041] The preparation method of the copolymer and the test of the microstructure in the polymer are the same as in Example 1, except that ETE is added according to the designed amount, and the specific amount is shown in Table 1.

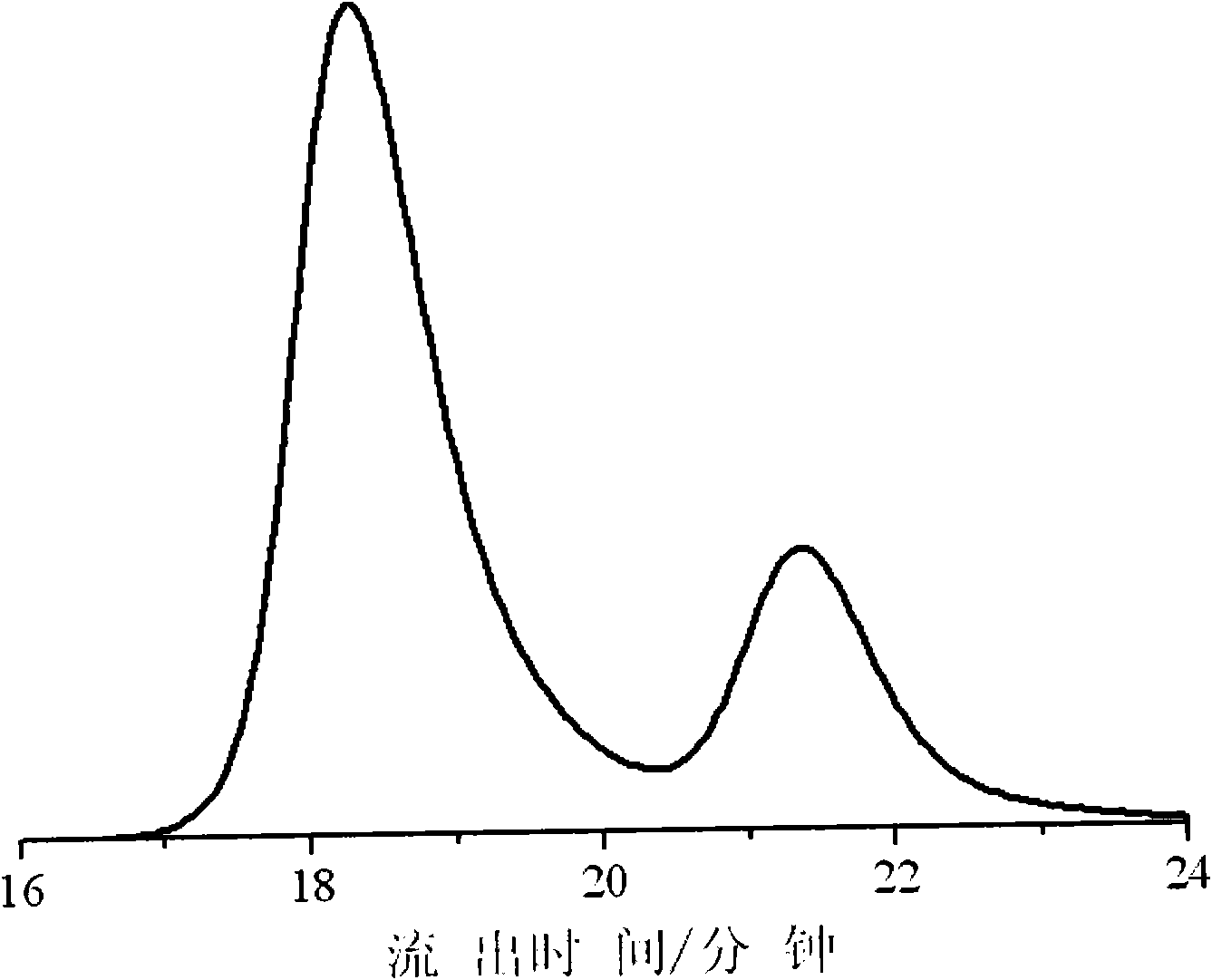

[0042] The 1,2-structure content, molecular weight, molecular weight distribution, and coupling efficiency measurement results of ETE addition, polymerization product are shown in Table 1, as can be seen from Table 1: the star-shaped solution-polymerized butadiene rubber prepared according to the present invention can be successfully carried out Coupling reaction, and the content of 1,2-structure in the copolymer is controllable.

[0043] Table 1 Molecular parameters and microstructure of star-shaped solution polybutylene rubber

[0044] Experiment number

Example 1 ...

Embodiment 10-18

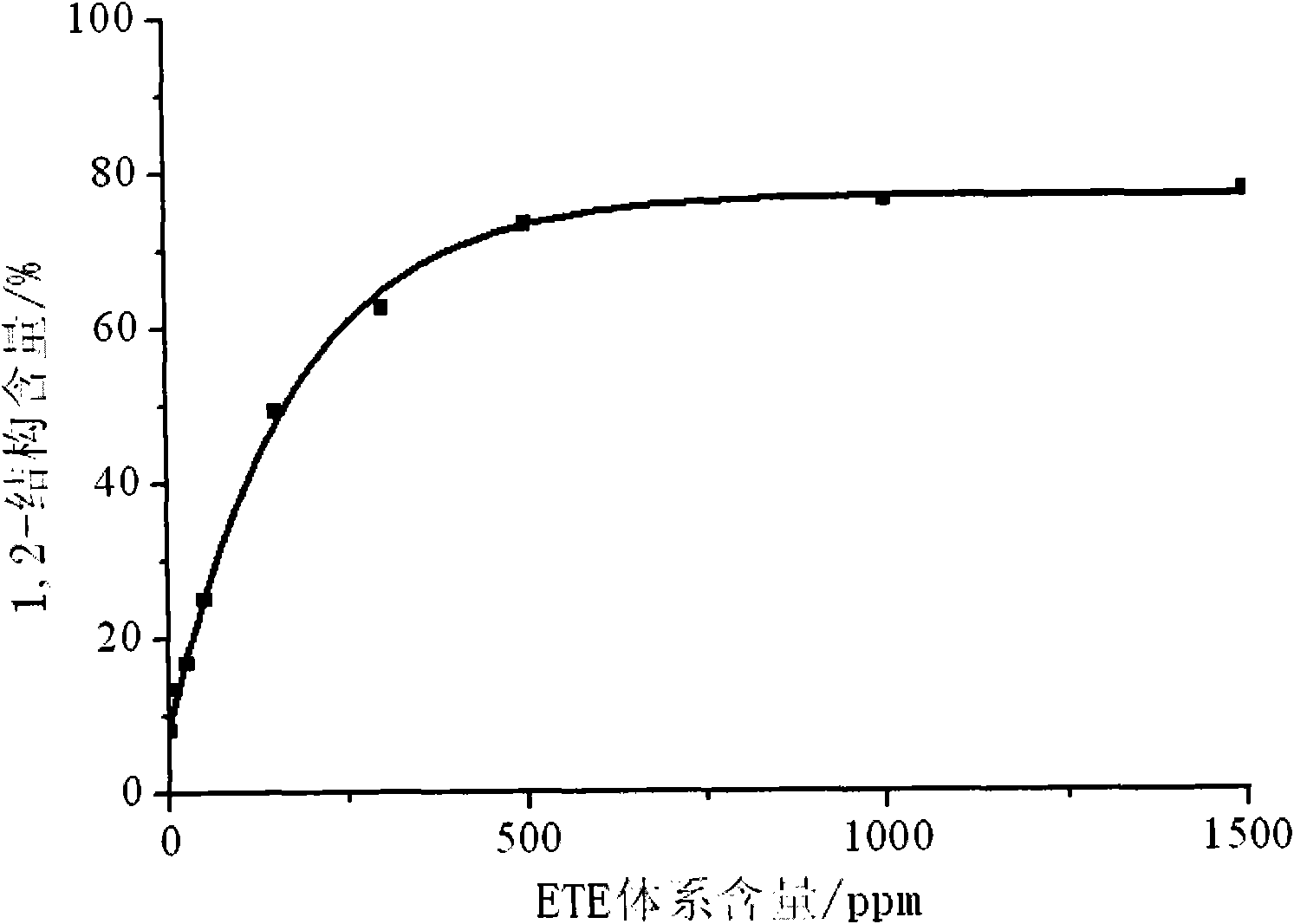

[0059] Examples 10-18 Cyclohexane system synthesis of star-shaped solution polybutadiene rubber (BD / IP=65 / 35, weight ratio)

[0060] The preparation method of the copolymer and the test of the microstructure in the polymer are the same as in Example 1, except that the polymerization solvent system is changed to 2600g of cyclohexane, the initiation temperature is changed to 50°C, and ETE is added according to the designed amount. The 1,2-structure content of the product is shown in Table 3.

[0061] Table 3 Microstructure of star-shaped solution polybutylene rubber

[0062] Experiment number

Example 10

Example 11

Example 12

Example 13

Example 14

ETE(g)

0.003

0.03

0.05

0.15

0.45

1,2-(%)

8.0

13.4

16.6

25.1

49.1

[0063] Table 3 (continued)

[0064] Experiment number

Example 15

Example 16

Example 17

Example 18

ETE(g)

0.9

1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com