Composition for manufacturing corrosion-resistant and abrasion-resistant coating as well as preparation method and application thereof

A composition and wear-resistant technology, applied in coatings, anti-corrosion coatings, devices for coating liquids on surfaces, etc., can solve the problems of thermal stability decline, impact strength, corrosion resistance and wear resistance of epoxy cured products Low damage performance, poor aging resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

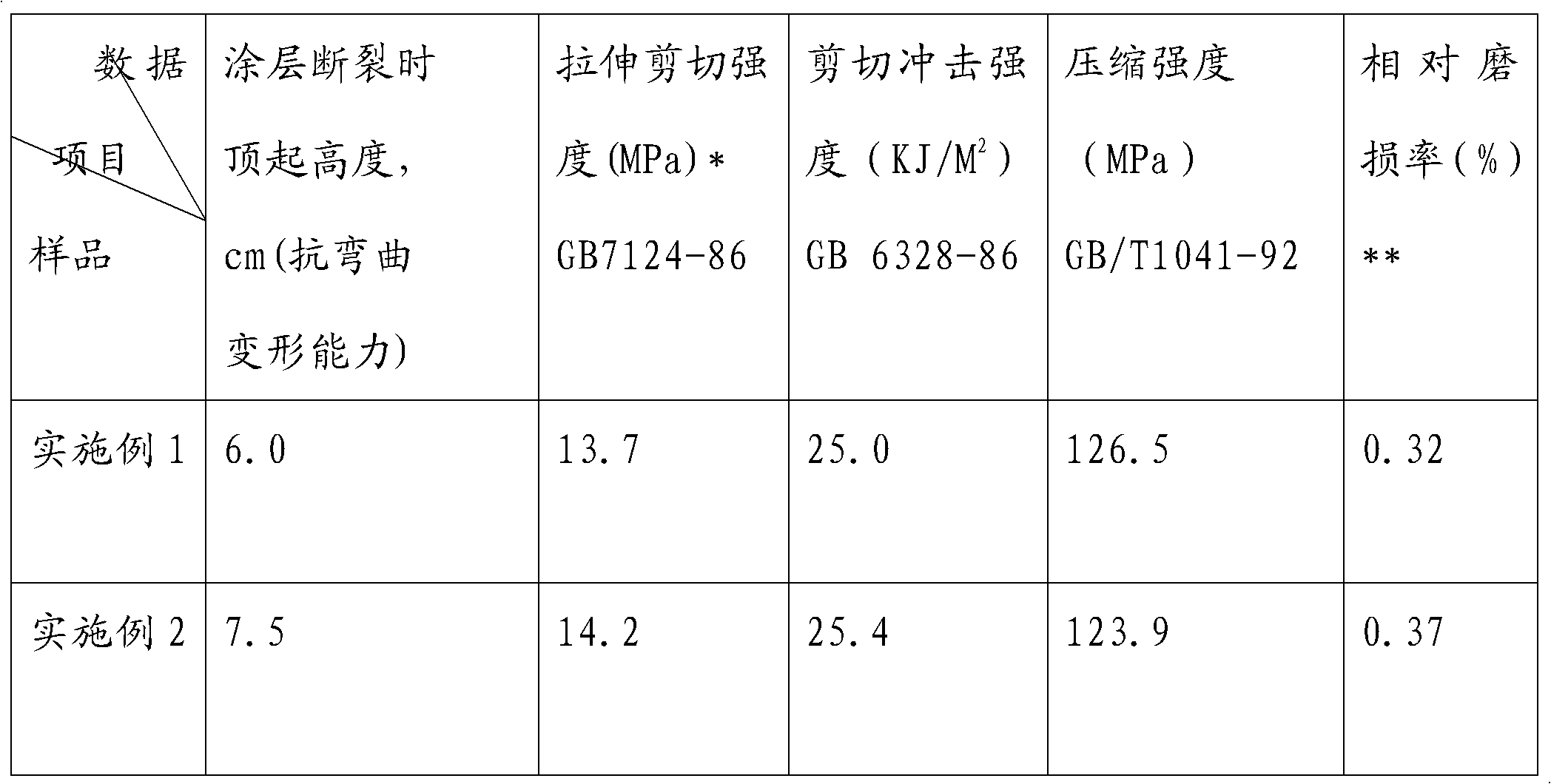

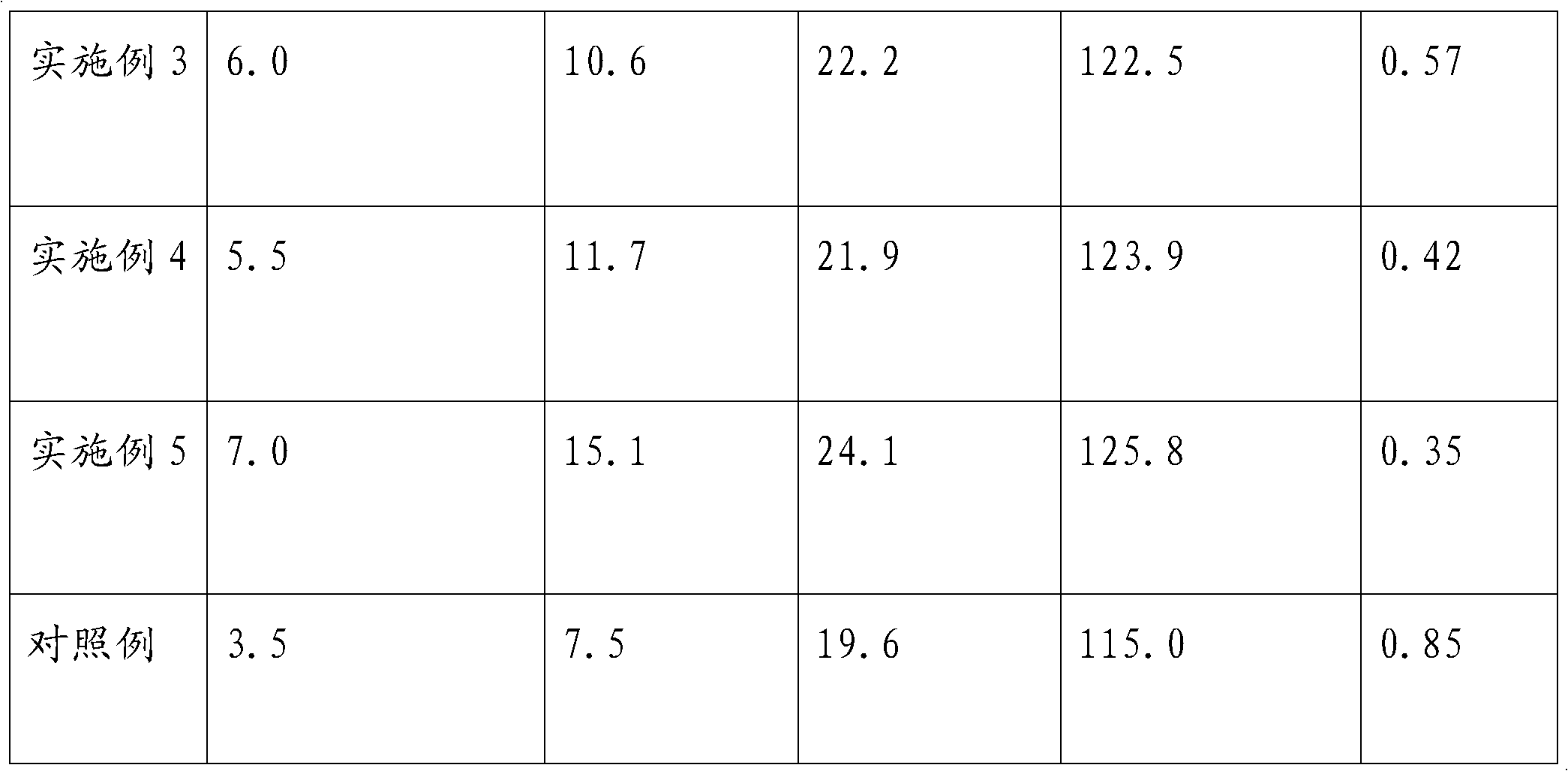

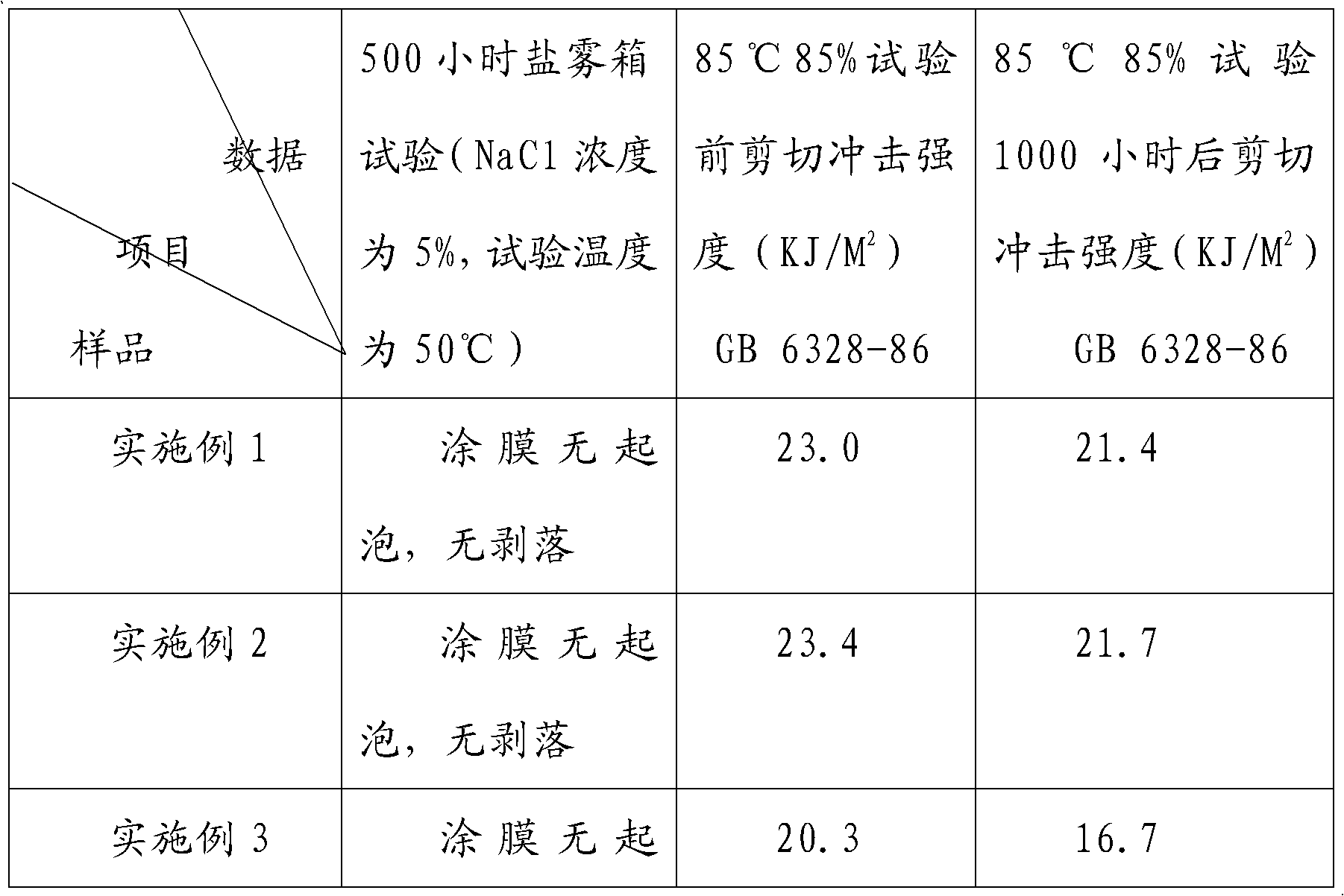

Examples

Embodiment 1

[0026] 1) Preparation of component A: 30 parts by weight of E51 epoxy resin, 5 parts of hyperbranched epoxy resin, 10 parts of octyl glycidyl ether, 0.6 parts of KH-560 coupling agent, 2 parts of Perenol S43 leveling agent Add one part into a double planetary power mixing mixer, and mechanically stir for 0.5 hours under the condition that the rotation speed is 500 rpm and the revolution speed is 15 rpm; then add 20 parts of platy corundum powder, 8 parts of glass fiber powder, quartz 8 parts of powder, 15 parts of talc powder, 8 parts of mica powder, under the conditions of rotation speed of 800 rpm and revolution speed of 20 rpm, mechanically stirred for 2.5 hours; then added 1.5 parts of fumed silica and stirred for 20 minutes , evacuate to -0.08Mpa until the foam disappears, and obtain component A, which is packaged and placed for use;

[0027] 2) Preparation of component B: 60 parts by weight of Versamine C-31 modified cycloaliphatic amine, 38 parts of H-15 modified polyam...

Embodiment 2

[0030] 1) Preparation of component A: 40 parts by weight of DER331 epoxy resin, 10 parts of hyperbranched epoxy resin, 6 parts of butyl glycidyl ether, 0.8 parts of KH-560 coupling agent, and 3 parts of Perenol F40 leveling agent Add one part into a double planetary power mixing mixer, and mechanically stir for 0.5 hours under the conditions of rotation speed of 500 rpm and revolution speed of 15 rpm; then add 25 parts of platy corundum powder, 10 parts of glass fiber powder, quartz 8 parts of powder, 15 parts of talcum powder, and 8 parts of mica powder, under the conditions of rotation speed of 800 rpm and revolution speed of 20 rpm, mechanically stirred for 2.5 hours; then added 2 parts of fumed silica and stirred for 20 minutes , evacuate to -0.08Mpa until the foam disappears, and obtain component A, which is packaged and placed for use;

[0031]2) Preparation of component B: put 69 parts by weight of JH-5953 modified cycloaliphatic amine, 30 parts of H-25 modified polyami...

Embodiment 3

[0034] 1) Preparation of component A: 50 parts by weight of NPEF-170 epoxy resin, 15 parts of hyperbranched epoxy resin, 12 parts of 1,4-butanediol diglycidyl ether, 0.5 parts of KH-560 coupling agent 1 part, 1 part of Perenol S43 leveling agent was added to the double planetary power mixing mixer, under the conditions of rotation speed of 500 rpm and revolution speed of 15 rpm, mechanically stirred for 0.5 hours; then added 25 parts of platy corundum powder , 8 parts of glass fiber powder, 10 parts of quartz powder, 15 parts of talcum powder, 12 parts of mica powder, under the condition that the rotation speed is 800 rpm and the revolution speed is 20 rpm, mechanically stir for 2.5 hours; then add gas phase 2 parts of silicon dioxide were stirred for 20 minutes, vacuumed to -0.08Mpa until the foam disappeared, and component A was obtained, packaged and placed for use;

[0035] 2) Preparation of component B: put 45 parts by weight of Versamine C-31 modified cycloaliphatic amin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com