Alveolate magnetic heat exchange material preparing technology

A magnetic heat exchange and honeycomb technology, which is applied in the field of processing and preparation of magnetic heat exchange materials, can solve the problems of poor particle density, strength and surface roughness, increased flow resistance of heat exchange medium, and decreased refrigeration capacity of refrigerators. Achieve the effect of improving comprehensive performance, small flow resistance and good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

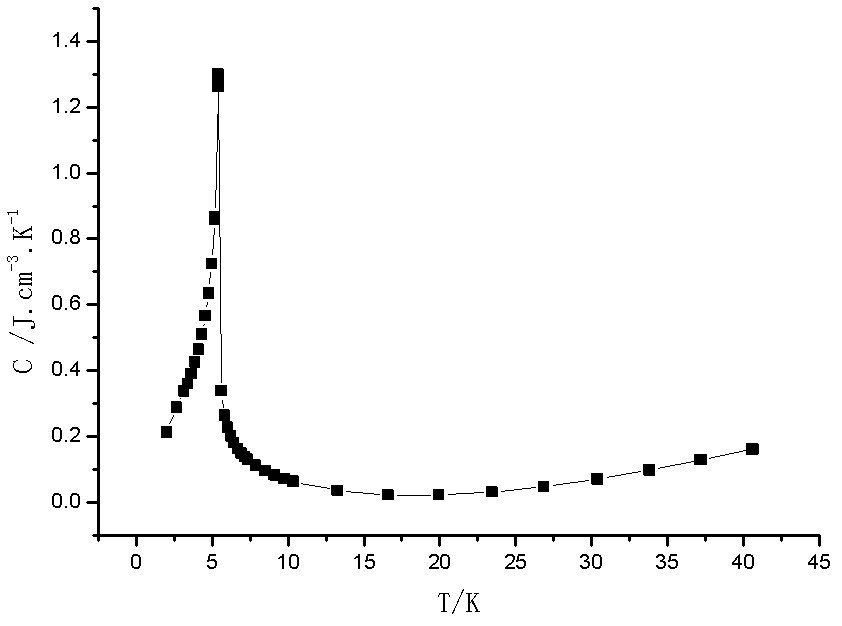

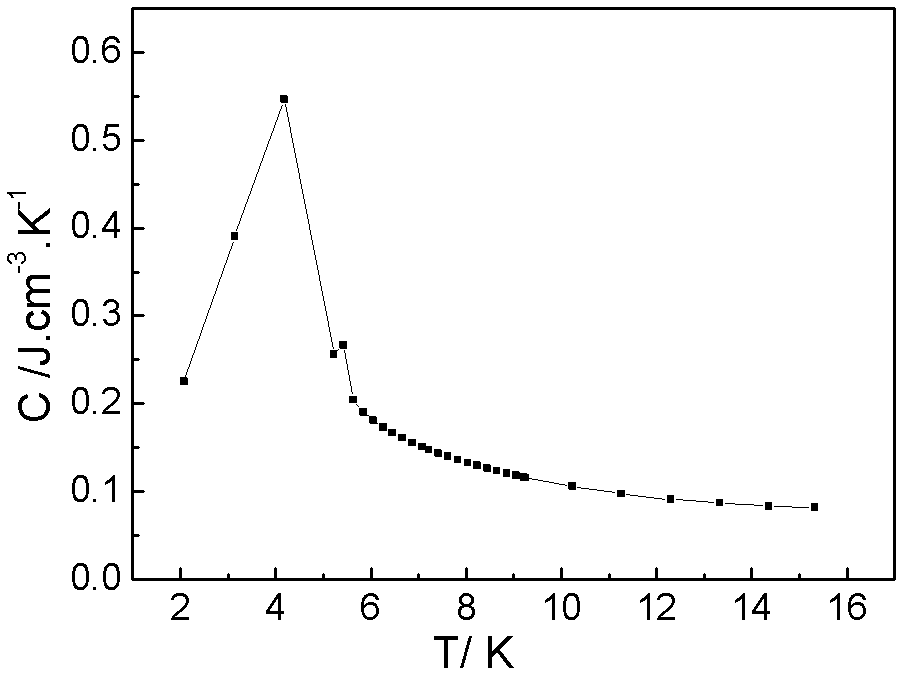

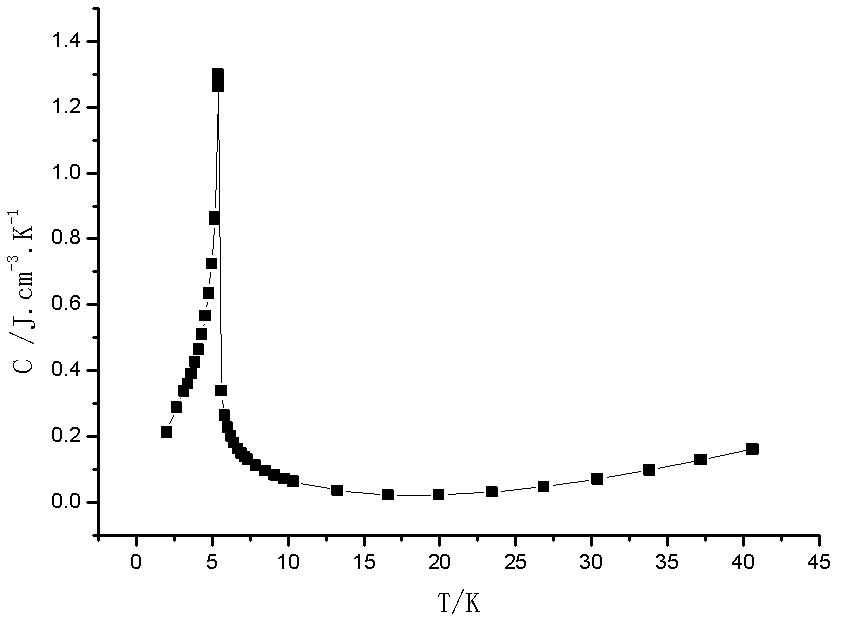

Image

Examples

Embodiment 1

[0030] According to the ratio of 5wt% low melting point P 2 o 5 -ZnO-MgO-Na 2 O glass+95wt%GOS Weigh the material, and use a mixing mixer to mix evenly for 3h; then, put the mixed powder into the kneader, and add 15wt% water, 6wt% plasticizer (glycerin: carboxymethyl Cellulose=1:2), 2wt% liquid paraffin, kneading for 0.5h, then put the kneaded mud into a vacuum mud mill for secondary mud refining, and adopt a circular hole structure of 300 holes / inch 2 The honeycomb porous mold is extruded with an extruder. Cut into a certain size according to the requirements, microwave drying for 10 minutes, drying in a vacuum oven at 80°C for 6 hours, and sintering at 900°C.

Embodiment 2

[0032] According to the ratio of 5wt% low melting point Na 2 O-Al 2 o 3 -B 2 o 3 Glass+95wt%GOS Weigh the material, and use a mixing mixer to mix evenly for 3h; then, put the mixed powder into the kneader, and add 12wt% water, 8wt% polyvinyl alcohol, 3wt% stearic acid, Knead for 1 hour, then enter the vacuum mud mill for secondary mud refining, and adopt a circular hole structure of 400 holes / inch 2 The honeycomb porous mold is extruded with an extruder. Cut into a certain size according to the requirements, microwave drying for 10 minutes, drying in a vacuum oven at 90°C for 5 hours, and sintering at 850°C.

Embodiment 3

[0034] According to the ratio of 6wt% low melting point ZnO-P 2 o 5 Glass+94wt% GdAlO3 Weigh the materials, and use a mixing mixer to mix them uniformly for 3 hours; then, put the mixed powder into a kneader, and add 12wt% water, 8wt% polyvinyl alcohol, 3wt% stearic acid, knead for 1h, and then enter Secondary mud refining is carried out in the vacuum mud refining machine, and the hole structure is circular with 400 holes / inch. 2 The honeycomb porous mold is extruded with an extruder. Cut to a certain size according to the requirements, microwave drying for 10 minutes, drying in a vacuum oven at 90°C for 5 hours, and sintering at 800°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com