Environmentally-friendly high-temperature-resistant synthetic base foam drilling fluid and preparation method thereof

A high-temperature resistant, synthetic-based technology, applied in the field of drilling, can solve the problems of poor temperature resistance, weak anti-pollution ability, unstable foam system, etc., and achieve good effect and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation steps of high-temperature oil-based foam stabilizer (oil-soluble polymer polybasic fatty acid alkanolamide ether) specifically include:

[0021] (1) Add 200g of dibasic acid (M=260), 80g of anhydrous methanol, and 1g of concentrated sulfuric acid in a 500mL glass reactor in sequence, and slowly raise the temperature to 85-90°C under stirring conditions, keep the temperature for 0.5h, and then add to the reaction Add 70g of anhydrous methanol to the vessel, keep the temperature constant for 1h, raise the temperature to 100°C, keep the temperature constant for 20min, cool down to 50°C, and discharge. Washing the reaction product with water until the pH value reaches neutrality to obtain polybasic fatty acid methyl esters;

[0022] (2) Add 100 g of the polybasic fatty acid methyl ester prepared in (1) into the aforementioned reactor, vacuum dehydrate, then add 100 g of diesel oil, 38 g of diethanolamine, and 0.8 g of NaOH, raise the temperature to 120 ° C, ...

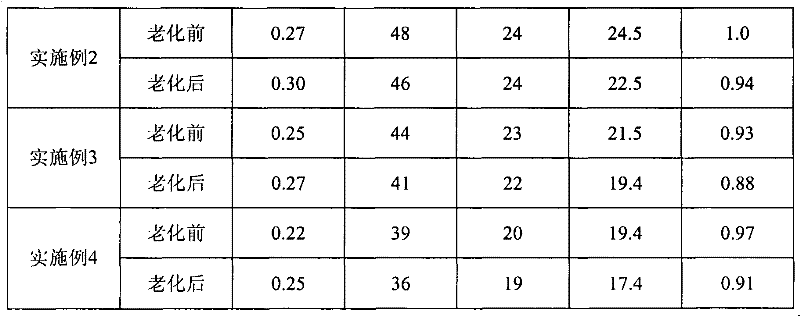

Embodiment 2

[0025] (1) Weigh 92g of α-olefin into a 100mL beaker, add 3g of the polybasic fatty acid alkanolamide ether synthesized in Example 1 and stir to dissolve, then add 3g of organic soil () under stirring to disperse the organic soil evenly, and then add 2g octadecylsulfonic acid, stirred gently to dissolve;

[0026] (2) Transfer the above-mentioned foam liquid to a high-speed stirrer, and stir the foam base liquid at a high speed of 12000r / min for 1 min to obtain the synthetic base foam drilling fluid.

Embodiment 3

[0028] (1) Weigh 95g of α-olefin in a 100mL beaker, add 2g of the polybasic fatty acid alkanolamide ether synthesized in Example 1 and stir to dissolve, then add 2g of organic soil under stirring to make the organic soil evenly dispersed, then add 1.5g Eicosylsulfonic acid, stirred gently to dissolve;

[0029] (2) Transfer the above-mentioned foam liquid to a high-speed stirrer, and stir the foam base liquid at a high speed of 12000r / min for 1 min to obtain the synthetic base foam drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com