Method for producing natural carotenoid by cultivating deinococcus radiodurans

A technology for Deinococcus radiodurans and carotene, which is applied in the field of producing natural carotenoids, can solve the problems of complex synthesis technology, toxicity, chromosomal aberration, etc., and achieves the effects of improving economic benefits, reducing pollution, and having no residual toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

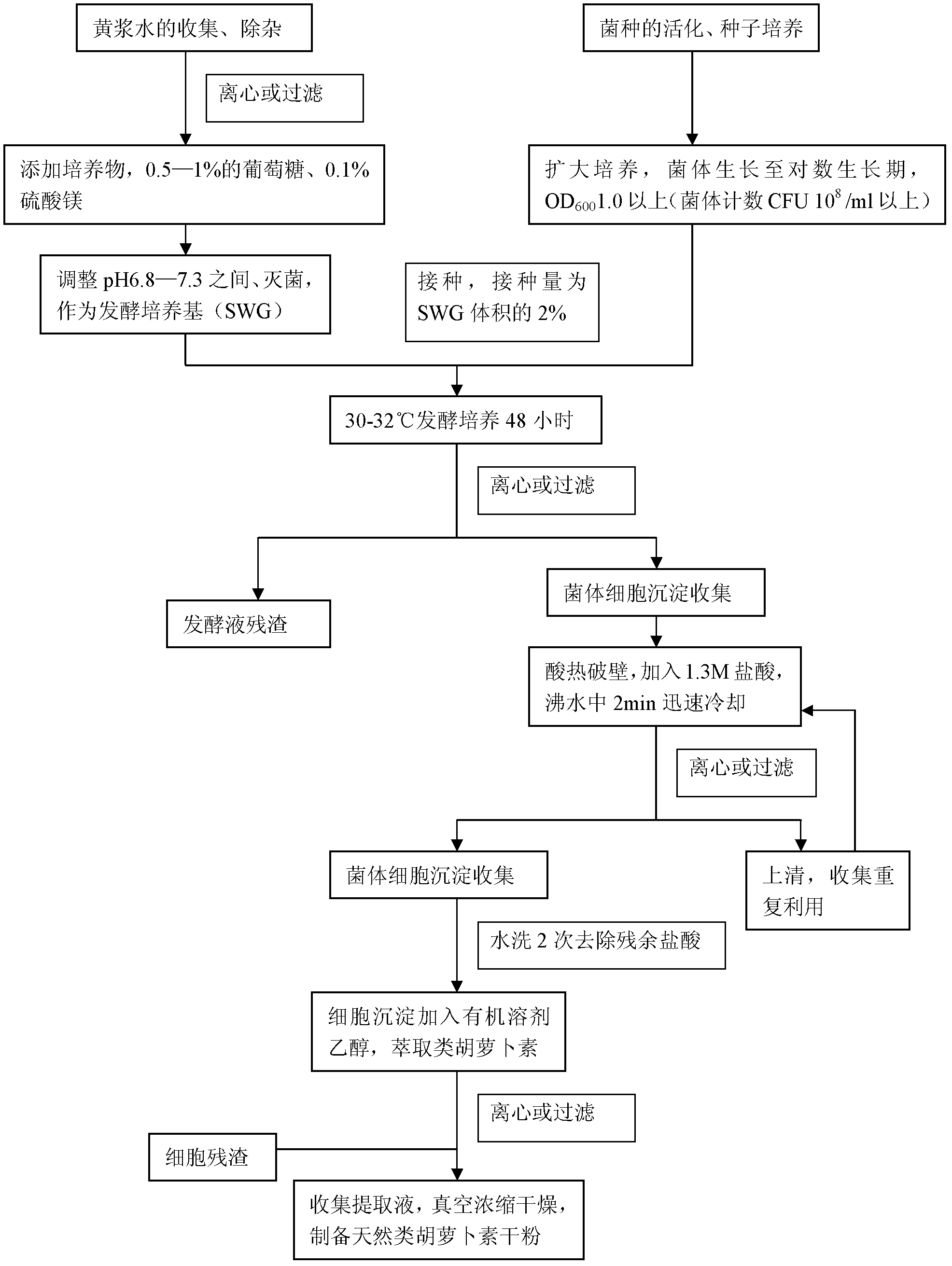

Image

Examples

Embodiment 1

[0018] Taking yellow pulp water, 1% glucose, 0.1% magnesium sulfate, and weakly acidic pH 6.8 medium for fermentation, acid heat breaking, and ethanol extraction as an example

[0019] (1) Collection and removal of yellow pulp water: After collecting yellow pulp water in the production process of tofu and other soybean products, centrifuge at 5000 rpm for 20 minutes at room temperature to remove impurities and solids.

[0020] (2) pH adjustment of yellow pulp water: yellow pulp water itself has strong acidity, adjust the pH value of yellow pulp water to 6.8 with 2.0mol / L NaOH.

[0021] (3) Sterilization of yellow pulp water: add 1% glucose and 0.1% magnesium sulfate to the yellow pulp water in (2) above, use high temperature and high pressure sterilization method, 121°C, 30 minutes, sterilize and fill until fermentation Fermentation culture in bottle as culture medium (SWG).

[0022] (4) Activation of strains, seed culture: Streak inoculation of Deinococcus radiodurans on the...

Embodiment 2

[0029] Take yellow pulp water, 0.5% glucose, 0.1% magnesium sulfate, weak alkaline pH7.3 medium fermentation culture, acid heat breaking, ethanol extraction as an example

[0030] (1) Collection and removal of yellow pulp water: After collecting yellow pulp water in the production process of tofu and other soybean products, centrifuge at 5000 rpm for 20 minutes at room temperature to remove impurities and solids.

[0031] (2) pH adjustment of yellow pulp water: yellow pulp water itself has strong acidity, adjust the pH value of yellow pulp water to 7.3 with 2.0mol / L NaOH.

[0032] (3) Sterilization of yellow pulp water: add 0.5% glucose and 0.1% magnesium sulfate to the yellow pulp water in (2) above, use high temperature and high pressure sterilization method, 121 ° C, 30 minutes, sterilize and fill until fermentation Fermentation culture in bottle as culture medium (SWG).

[0033](4) Activation of strains, seed culture: Streak inoculation of Deinococcus radiodurans on the s...

Embodiment 3

[0040] Take yellow pulp water, 1% glucose, 0.1% magnesium sulfate, medium fermentation culture of weak acid pH6.8, acid heat breaking, acetone / methanol extraction as an example

[0041] (1) Collection and removal of yellow pulp water: After collecting yellow pulp water in the production process of tofu and other soybean products, centrifuge at 5000 rpm for 20 minutes at room temperature to remove impurities and solids.

[0042] (2) pH adjustment of yellow pulp water: yellow pulp water itself has strong acidity, adjust the pH value of yellow pulp water to 7.3 with 2.0mol / L NaOH.

[0043] (3) Sterilization of yellow pulp water: Add 1% glucose and 0.1% magnesium sulfate to the yellow pulp water in (2) above, use high temperature and high pressure sterilization method, 121 ° C, 30 minutes, and fill it to Fermentation culture in fermentation flasks as culture medium (SWG).

[0044] (4) Activation of strains, seed culture: Streak inoculation of Deinococcus radiodurans on the seed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com