Method for growing cerium-doped alumina-yttrium aluminum garnet eutectic fluorescent material

A technology of yttrium aluminum garnet and growth method, which is applied in the growth field of cerium-doped alumina-yttrium aluminum garnet eutectic fluorescent material, which can solve the problems of component segregation, small size and complexity, and reduce carbon pollution situation, eliminate interface disturbance, and avoid the effect of uneven composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

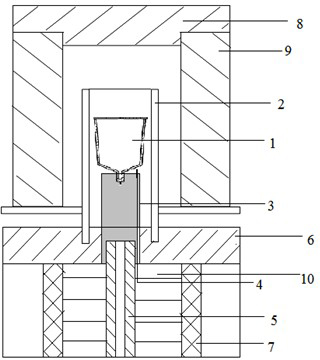

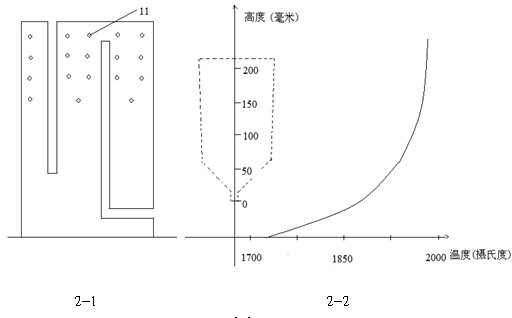

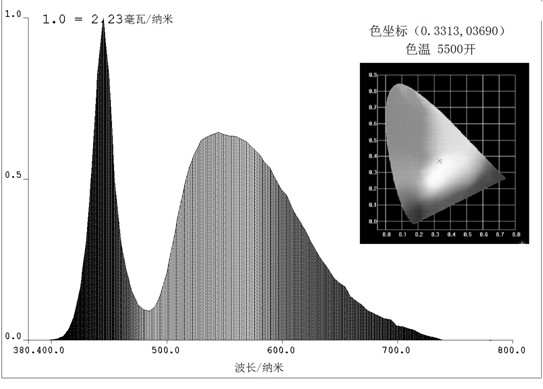

[0026] The size of the crucible made of molybdenum (Mo) is Φ55 x 150mm, the taper of the crucible bottom is 100°, the raw material ratio parameters are selected as a=0.825, b=0.17325, c=0.0035, and the doping ratio of Ce in the YAG phase is 0.01, That is (Y 0.99 Ce 0.01 ) 3 Al 5 o 12

[0027] α-Al 2 0 3 Powder (purity 99.999%), Y 2 o 3 Powder (purity 99.999%) and CeO 2 Powder (purity 99.999%) as raw material, according to Al 2 o 3 : Y 2 o 3 : CeO 2 =0.825:0.17325:0.0035 Molar ratio Weigh about 300 g of the raw materials in total, wet mix the raw materials in ethanol for 12 hours with a ball mill, and dry the ethanol in an oven to obtain a raw material powder. After pressing and forming with a hydraulic press, it is fired at 1200 ° C for 10 hours and then formed into blocks. Put Al into the seed crystal tank of the crucible in the temperature gradient furnace 2 o 3 Seed crystal, then put in the fired raw material and cover the crucible cover and put it into ...

Embodiment 2

[0031] The size of the crucible made of molybdenum (Mo) is Φ55 x 150mm, the taper of the crucible bottom is 100°, the raw material ratio parameters are selected as a=0.815, b=0.17945, c=0.0111, and the doping ratio of Ce in the YAG phase is 0.03, That is (Y 0.97 Ce 0.03 ) 3 Al 5 o 12

[0032] α-Al 2 o 3 Powder (purity 99.999%), Y 2 o 3 Powder (purity 99.999%) and CeO 2 Powder (purity 99.999%) as raw material, according to Al 2 o 3 : Y 2 o 3 : CeO 2 =0.815: 0.17945: 0.0111 molar ratio A total of about 300 g of raw materials was weighed, wet-mixed with ethanol for 12 hours using a ball mill, and dried in an oven to remove ethanol to obtain a raw material powder. After pressing and forming with a hydraulic press, it is fired at 1200 ° C for 10 hours and then formed into blocks. Put Al into the seed crystal tank of the crucible in the temperature gradient furnace 2 o 3 Seed crystal, then put in the fired raw material and cover the crucible cover and put it into...

Embodiment 3

[0036] The size of the crucible made of molybdenum (Mo) is Φ55 x 150mm, the taper of the crucible bottom is 100°, the raw material ratio parameters are selected as a=0.775, b=0.2115, c=0.027, and the doping ratio of Ce in the YAG phase is 0.06, That is (Y 0.94 Ce 0.06 ) 3 Al 5 o 12

[0037] α-Al 2 0 3 Powder (purity 99.999%), Y 2 o 3 Powder (purity 99.999%) and CeO 2 Powder (purity 99.999%) as raw material, according to Al 2 o 3 : Y 2 o 3 : CeO 2 =0.775: 0.2115: 0.027 molar ratio A total of about 300 g of raw materials was weighed, wet-mixed with ethanol for 12 hours using a ball mill, and dried in an oven to remove ethanol to obtain a raw material powder. After pressing and forming with a hydraulic press, it is fired at 1200 ° C for 10 hours and then formed into blocks. Put Al into the seed crystal tank of the crucible in the temperature gradient furnace 2 o 3 Seed crystal, then put in the fired raw material and cover the crucible cover and put it into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com