Determination method of pulp polymerization degree distribution

A method for measuring the degree of polymerization, which is applied in the fields of chemical industry and textiles, can solve problems such as the inability to accurately obtain the molecular weight of pulp cellulose, the size of the molecular chain, the inability to understand the distribution of the degree of polymerization, and the uneven degree of polymerization of pulp. The detection method is simple and fast, the strength is guaranteed, and the detection cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

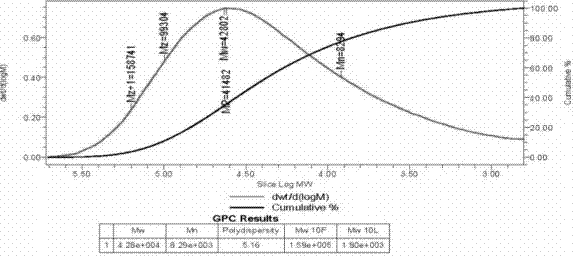

Embodiment 1

[0027] A. Weigh 2 grams of wood pulp samples, disperse the plate-like wood pulp into single fibers with a fiber dissociation device, and bake in an oven at 52°C for 4 hours until the water content is <5%;

[0028] B. Put 250 milliliters of dichloromethane and 115 grams of fuming nitric acid with a concentration of 99% into a 250 milliliter conical flask with a ground stopper, and place it in an ice-salt bath to cool to -5°C, and then slowly add 76 grams of phosphorus pentoxide, during which the temperature is kept below 0°C. When the temperature rises to 0°C, the addition of phosphorus pentoxide is stopped, and it is cooled to -5°C in ice salt water before continuing to add phosphorus pentoxide. After the mixed acid is prepared, the Erlenmeyer flask is taken out from the ice-salt water bath and put into the dried wood pulp sample, the bottle stopper is plugged, and the nitration reaction is carried out by rotating and shaking, the temperature is controlled at 25°C, and the reac...

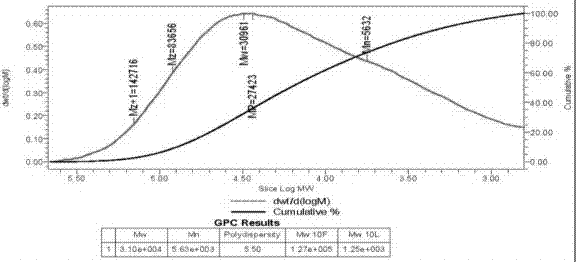

Embodiment 2

[0034] A. Weigh 2 grams of cotton pulp sample, disperse the plate-shaped cotton pulp into single fibers with a fiber dissociation device, and dry in an oven at 50°C for 4.5 hours until the water content is <5%;

[0035] B. Put 250 milliliters of dichloromethane and 115 grams of fuming nitric acid with a concentration of 99% into a 250 milliliter conical flask with a ground stopper, and place it in an ice-salt bath to cool to -5°C, and then slowly add 76 grams of phosphorus pentoxide, during which the temperature is kept below 0°C. When the temperature rises to 0°C, the addition of phosphorus pentoxide is stopped, and it is cooled to -5°C in ice salt water before continuing to add phosphorus pentoxide. After the mixed acid is prepared, take the Erlenmeyer flask out of the ice-salt water bath and put it into the dried cotton pulp sample, plug the bottle stopper, rotate and shake to carry out the nitration reaction, the temperature is controlled at 18°C, and the reaction is 0.5 ho...

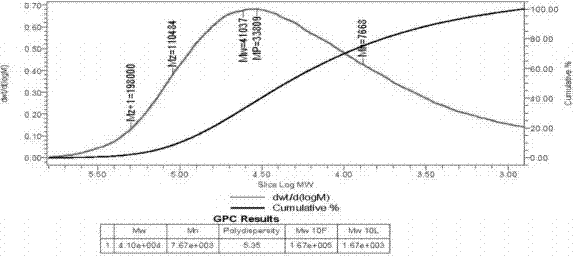

Embodiment 3

[0041] A, take 2 grams of bamboo pulp samples, disperse the plate-shaped bamboo pulp into single fibers with a fiber dissociator, and dry in a 52°C oven for 4 hours until the water content<5%;

[0042] B. Put 250 milliliters of dichloromethane and 115 grams of fuming nitric acid with a concentration of 99% into a 250 milliliter conical flask with a ground stopper, and place it in an ice-salt bath to cool to -5°C, and then slowly add 76 grams of phosphorus pentoxide, during which the temperature is kept below 0°C. When the temperature rises to 0°C, the addition of phosphorus pentoxide is stopped, and it is cooled to -5°C in ice salt water before continuing to add phosphorus pentoxide. After the mixed acid is prepared, the Erlenmeyer flask is taken out from the ice-salt water bath and put into the dried bamboo pulp sample, the bottle stopper is plugged, and the nitrification reaction is carried out by rotating and shaking. The temperature is controlled at 10°C and the reaction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com