Thin film solar cell and method for manufacturing the same

The invention relates to a technology of a solar cell and a manufacturing method, which can be applied to circuits, photovoltaic power generation, electrical components, etc., and can solve the problems of insufficient coverage of a buffer layer film, reduced conversion efficiency, and increased carrier recombination probability. The effect of increasing conversion efficiency and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

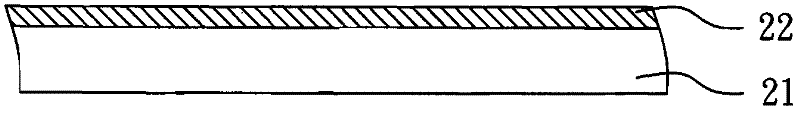

[0024] Such as Figure 2A As shown, a substrate 21 is provided, and a molybdenum layer is deposited on the substrate 21 by sputtering, and the molybdenum layer is used as a first electrode 22 . In this embodiment, the substrate 21 is a glass substrate.

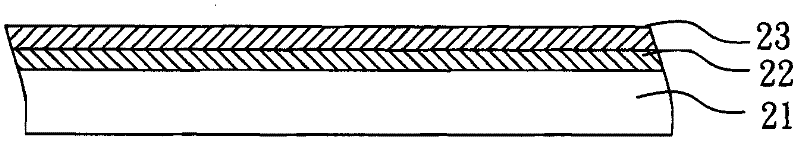

[0025] Then, if Figure 2B As shown, a barrier layer 23 that is conductive and does not easily react with selenium or sulfur is deposited on the first electrode 22 by sputtering or evaporation. In this embodiment, the barrier layer 23 is made of Al. Here, the barrier layer 23 can not only prevent the first electrode 22 from forming selenium or sulfur compounds in the subsequent selenization or sulfurization process, but also can be used as an electrode material because the barrier layer 23 has conductivity.

[0026] Such as Figure 2C As shown, a molybdenum-containing metal layer 24 is deposited on the barrier layer 23 by sputtering. In this embodiment, the molybdenum-containing metal layer 24 is a molybdenum layer, and t...

Embodiment 2

[0032] The thin film solar cell and its manufacturing method in this embodiment are the same as in Embodiment 1, except that the material of the barrier layer 23 in this embodiment is La metal doped with Al. Since the material of the barrier layer 23 in this embodiment is La metal doped with Al, in the subsequent selenization process, the aluminum element in the barrier layer 23 will diffuse to the absorber layer 25a, and then the absorber layer 25a is doped with Al in a gradient. , to achieve a gradient energy gap of the absorbing layer.

Embodiment 3

[0034] The thin-film solar cell and its manufacturing method in this embodiment are the same as in Embodiment 1, except that the material of the molybdenum-containing metal layer 24 in this embodiment is molybdenum metal doped with Al. Since the material of the molybdenum-containing metal layer 24 in this embodiment is molybdenum metal doped with Al, in the subsequent selenization process, the aluminum element in the molybdenum-containing metal layer 24 will diffuse into the absorbing layer 25a, thereby making the absorbing layer 25a have a gradient Al doping, and to achieve a gradient absorption layer energy gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com