Phosphorous diffusion method for polycrystalline silicon solar battery

A solar cell and phosphorus diffusion technology, applied in diffusion/doping, chemical instruments and methods, circuits, etc., can solve problems affecting the photoelectric conversion efficiency of crystalline silicon solar cells, improve oxidation quality, reduce pollution, and increase minority carrier life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

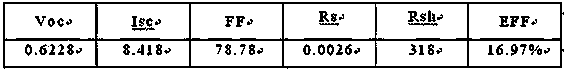

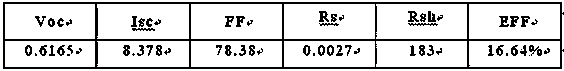

Embodiment 1

[0024] A phosphorus diffusion method for a polycrystalline silicon solar cell, comprising the steps of:

[0025] (1) Place the silicon wafer to be treated in a diffusion furnace, so that the temperature of each temperature zone in the furnace rises to 800 ° C, and the atmosphere in the furnace is a nitrogen environment of 10 L / min;

[0026] (2) After the temperature in the furnace is stabilized, the temperature of each temperature zone in the furnace is raised to 850 °C, and at the same time, 1 L / min of HCl-carrying gas is evenly introduced for 20 min;

[0027] (3) Stop feeding HCl-carrying gas, and only feed 1.5 L / min dry oxygen for 10 min;

[0028] (4) Evenly introduce 1 L / min of phosphorus-carrying source gas and 1.5 L / min of dry oxygen, and the diffusion time is 20 minutes;

[0029] (5) Stop feeding the phosphorus-carrying source gas, and only feed 1 L / min of HCl-carrying gas for 10 minutes;

[0030] (6) Stop feeding HCl-carrying gas, and only feed 1.5 L / min dry oxygen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com