Method for making dehydrated rice

A technology of dehydrated rice and rice, which is applied in the food field, can solve the problems of poor taste of dehydrated rice and low rehydration of dehydrated rice, and achieve the effect of improving rehydration and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

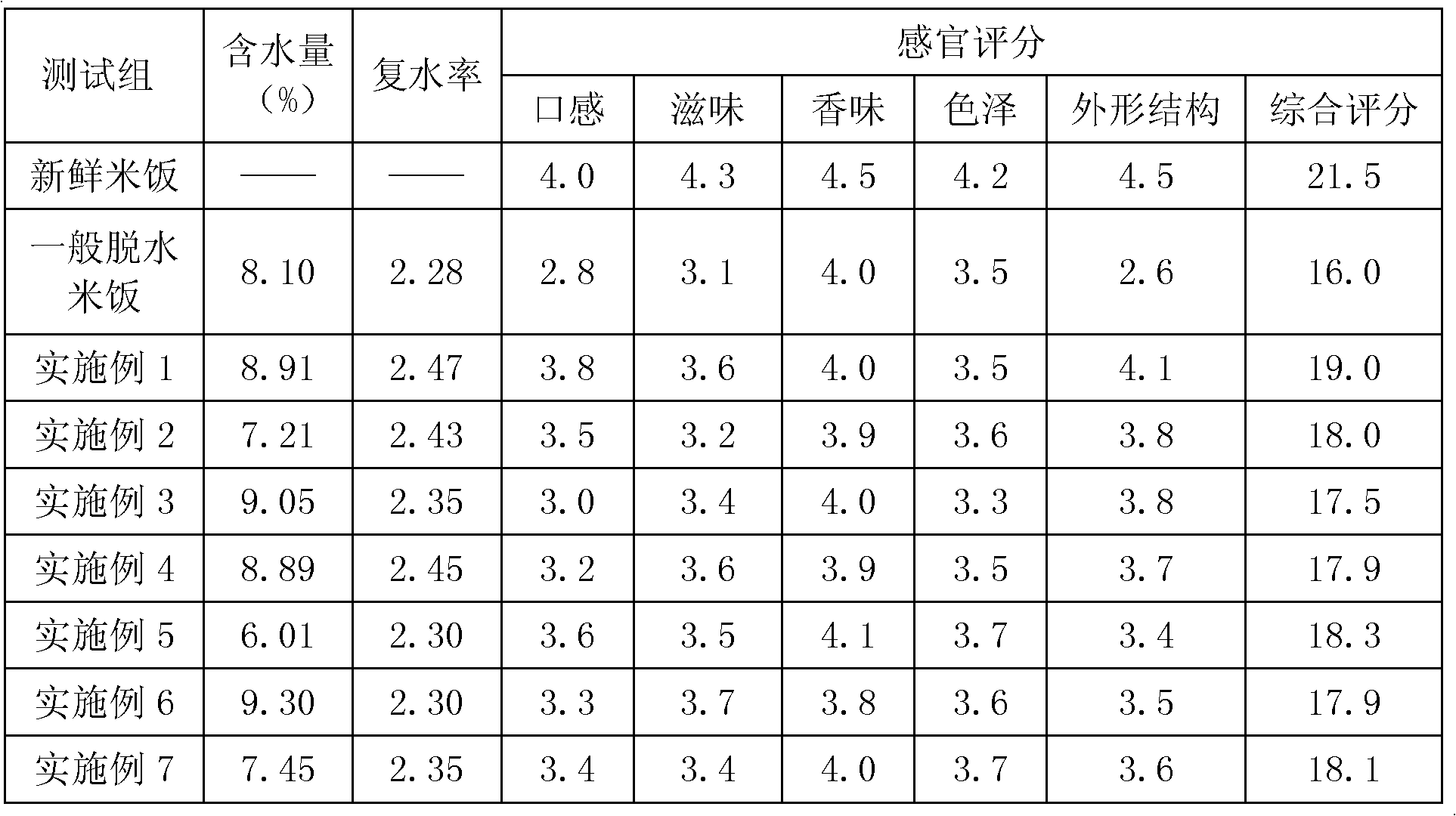

Examples

Embodiment 1

[0017] 1. After conventional selection and elutriation, the rice raw materials are subjected to osmosis treatment, that is, sorbitol solution with a mass concentration of 50% is soaked for 80 minutes at 30°C; then the rice is boiled under normal pressure cooked;

[0018] 2. Soak the cooked rice with enzyme solution, that is, weigh the protease (pepsin (pig gastric mucosa) of Shanghai Jiahe Biotechnology Co., Ltd.) at an amount of 0.5 g / (100 g of rice), and add the protease to the rice , and add water to soak for 20 minutes at room temperature;

[0019] 3. After soaking in the enzyme solution, add 5% of the mass of the rice into the rice as a discrete liquid, the discrete liquid is composed of water, ethanol and fatty acid sucrose esters, wherein the fatty acid sucrose esters account for 1% of the mass of the discrete liquid; way to break up the rice;

[0020] 4. After the rice has been discretely processed, it is first dried with 690W microwave for 9 minutes, then dried with...

Embodiment 2

[0022] 1. After conventional selection and elutriation, the rice raw material is treated with osmotic sugar, that is, using a sorbitol solution with a mass concentration of 20%, soaking it for 120 minutes at 60°C; then steaming the rice under normal pressure cooked;

[0023] 2. Soak the steamed rice with enzyme solution, that is, weigh the protease (neutral protease from Shanghai Jiahe Biotechnology Co., Ltd.) at an amount of 0.2 g / (100 g of rice), add the protease to the rice, and add water to the Soak for 10 minutes at room temperature;

[0024] 3. After soaking in the enzyme solution, add 2% of the mass of the rice into the rice as a discrete liquid, the discrete liquid is composed of water, ethanol and fatty acid glycerides, wherein the fatty acid glycerides account for 1.5% of the mass of the discrete liquid; way to break up the rice;

[0025] 4. After the rice has been discretely processed, it is first dried with 600W microwave for 5 minutes, then dried with 90°C hot a...

Embodiment 3

[0027] 1. After conventional selection and elutriation of the rice raw materials, carry out sugar infiltration treatment, that is, use a sorbitol solution with a mass concentration of 70%, soak for 80 minutes at 60°C; then cook the rice under normal pressure cooked;

[0028] 2. Soak the cooked rice with enzyme solution, namely take cellulase (cellulase (R-10) produced by Shanghai Aiyan Biotechnology Co., Ltd.) in an amount of 0.4 g / (100 g of rice), and Add cellulase to rice, add water and soak for 20 minutes at room temperature;

[0029] 3. After soaking in the enzyme solution, add 10% of the mass of the rice into the rice as a discrete liquid, the discrete liquid is composed of water, ethanol and fatty acid propylene glycol ester, wherein the fatty acid propylene glycol ester accounts for 1% of the mass of the discrete liquid; way to break up the rice;

[0030] 4. After the rice has been discretely processed, it is first dried with 800W microwave for 15 minutes, then dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com