Hot melt pressure-sensitive adhesive and preparation method thereof

A technology of hot-melt pressure-sensitive adhesive and isoprene, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, sheet-like delivery, etc. problem, achieve the effect of maintaining thermal stability and improving drug release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

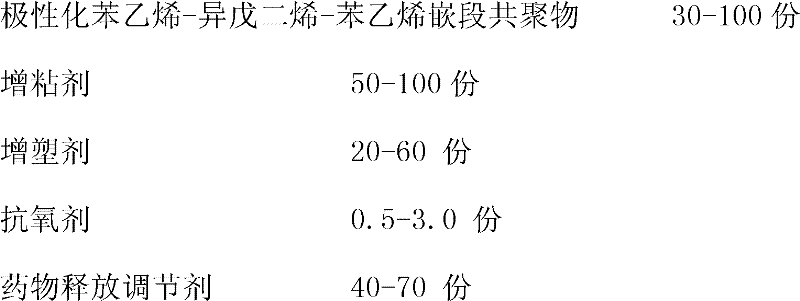

Method used

Image

Examples

Embodiment 1

[0038] 130℃, filled with N 2 In a self-made airtight container, add 50 parts by weight of SiS, 1.5 parts by weight of N, zinc N-dibutylaminodithiocarbamate, 40 parts by weight of mineral oil with 10% epoxy degree successively, and the materials are all in about 15 minutes Melting; then adding 90 parts by weight of petroleum resin, about 30 minutes to complete melting; heating to 180 ° C, rotating speed 500r / min, mechanical stirring for 30 minutes, to obtain a uniformly mixed SIS single-phase hot melt adhesive.

[0039] At 160-180°C, filled with N 2 In a self-made airtight container, the SIS single-phase hot melt adhesive prepared above is mixed with 60 parts by weight of the drug release modifier methyl methacrylate / trimethylaminoethyl methacrylate chloride, N 2protection, rotating speed 500r / min, and mechanical stirring for 30 minutes to obtain a uniformly mixed two-phase hot-melt pressure-sensitive adhesive.

[0040] Mix and dissolve 6 parts by weight of luteolin and 6 par...

Embodiment 2

[0042] 130℃, filled with N 2 In the self-made airtight container, add 50 parts by weight of SIS, 1.5 parts by weight N of epoxy degree of 10% successively, zinc N-dibutylcarbamate, 40 parts by weight of mineral oil, all materials in about 15min Melting; then adding 90 parts by weight of petroleum resin, about 30 minutes to complete melting; heating to 180 ° C, rotating speed 500r / min, mechanical stirring for 30 minutes, to obtain a uniformly mixed SIS single-phase hot melt adhesive.

[0043] At 160-180°C, filled with N 2 In a self-made airtight container, the SIS single-phase hot melt adhesive prepared above is mixed with 60 parts by weight of the drug release modifier methyl methacrylate / trimethylaminoethyl methacrylate chloride, N 2 protection, rotating speed 500r / min, and mechanical stirring for 30 minutes to obtain a uniformly mixed two-phase hot-melt pressure-sensitive adhesive.

[0044] 6 parts by weight of baicalin and 6 parts by weight of propylene glycol are mixed a...

Embodiment 3

[0046] 130℃, filled with N 2 In the self-made airtight container of 50 parts by weight graft rate 5% maleic anhydride graft SIS, 1.5 parts by weight N, N-dibutylcarbamate zinc, 40 parts by weight mineral oil successively , the material is completely melted in about 15 minutes; then 90 parts by weight of petroleum resin is added, and it is completely melted for about 30 minutes; the temperature is raised to 180°C, the speed is 500r / min, and the mechanical stirring is carried out for 30 minutes to obtain a uniformly mixed SIS single-phase hot melt adhesive.

[0047] At 160-180°C, filled with N 2 In a self-made airtight container, the SIS single-phase hot melt adhesive prepared above is mixed with 60 parts by weight of the drug release modifier methyl methacrylate / trimethylaminoethyl methacrylate chloride, N 2 protection, rotating speed 500r / min, and mechanical stirring for 30 minutes to obtain a uniformly mixed two-phase hot-melt pressure-sensitive adhesive.

[0048] Mix and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com