Coating for improving bioactivity of stainless-steel bone lamella and bone nail

A biologically active, stainless steel technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of allergies, infection and loosening, and achieve inhibition of dissolution and exudation, smooth surface and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

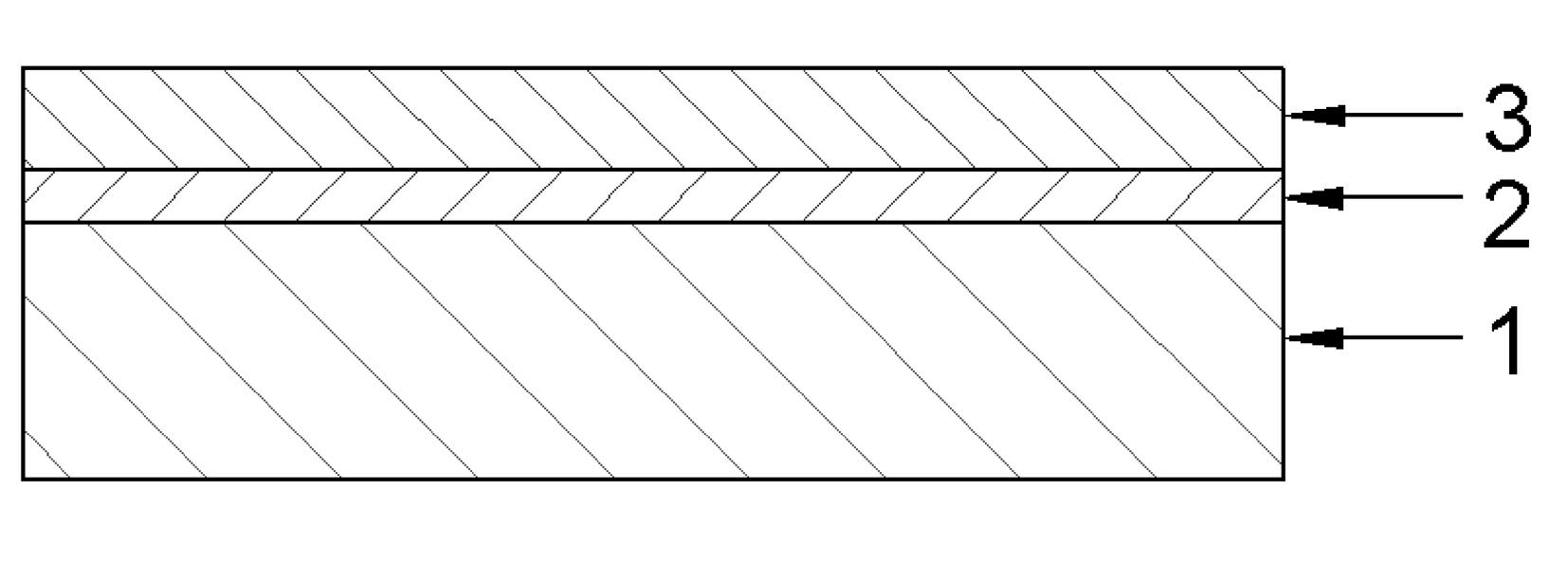

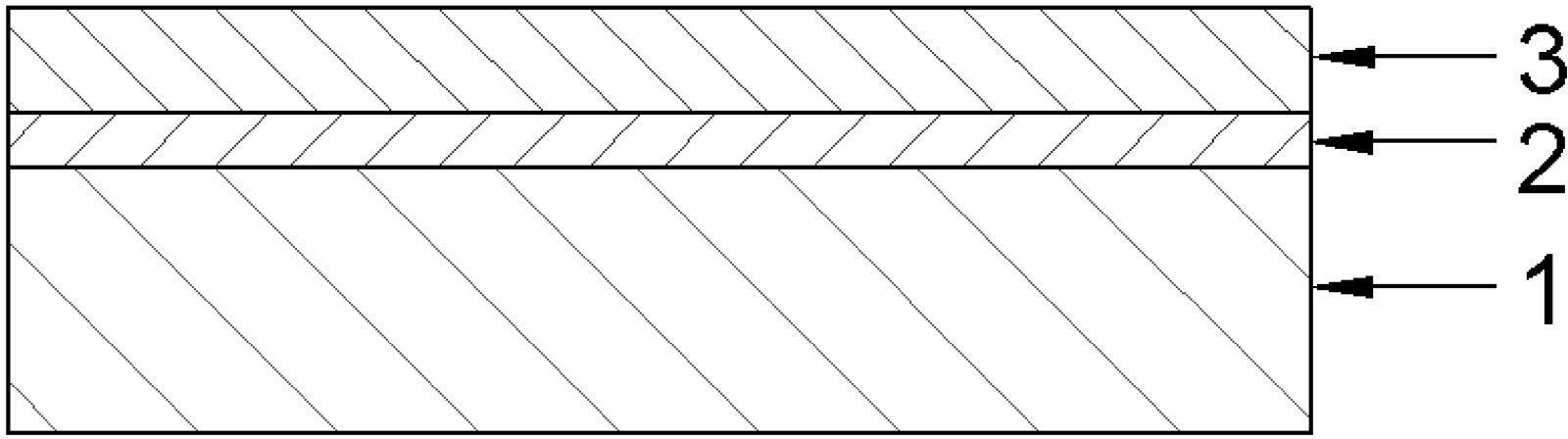

Embodiment 1

[0018] Step 1: The stainless steel plate or wire is processed into bone plate and bone nail blanks that meet the requirements of the industry standard, and the bone plate and bone nail blanks are electrochemically polished, and then cleaned with acetone, distilled water and absolute ethanol in sequence; The second step: grow the composite coating in ultra-high vacuum magnetron sputtering equipment, the cathode uses high-purity metal Ti and hot-pressed sintered ceramic TiB 2 as the target; first, grow a pure metal Ti layer with a thickness of 50nm, and the process parameters are as follows: sputtering power 10W, working pressure 0.35Pa, substrate heating temperature 250°C, substrate negative bias 0V; then, grow TiB 2 layer, the thickness is 450nm, and the process parameters are as follows: sputtering power 120W, working pressure 0.5Pa, substrate heating temperature 450°C, substrate negative bias voltage 60V; total thickness of composite coating 500nm; third step: fully grown bon...

Embodiment 2

[0020] Step 1: The stainless steel plate or wire is processed into bone plate and bone nail blanks that meet the requirements of the industry standard, and the bone plate and bone nail blanks are electrochemically polished, and then cleaned with acetone, distilled water and absolute ethanol in sequence; The second step: grow the composite coating in ultra-high vacuum magnetron sputtering equipment, the cathode uses high-purity metal Ti and hot-pressed sintered ceramic TiB 2 as the target; first, grow a pure metal Ti layer with a thickness of 100nm, and the process parameters are as follows: sputtering power 20W, working pressure 0.3Pa, substrate heating temperature 250°C, substrate negative bias 0V; then, grow TiB 2 layer with a thickness of 900nm, and the process parameters are as follows: sputtering power 150W, working pressure 0.35Pa, substrate heating temperature 450°C, substrate negative bias 60V; the total thickness of the composite coating is about 1μm; the third step: f...

Embodiment 3

[0022] Step 1: The stainless steel plate or wire is processed into bone plate and bone nail blanks that meet the requirements of the industry standard, and the bone plate and bone nail blanks are electrochemically polished, and then cleaned with acetone, distilled water and absolute ethanol in sequence; The second step: grow the composite coating in ultra-high vacuum magnetron sputtering equipment, the cathode uses high-purity metal Ti and hot-pressed sintered ceramic TiB 2 as the target; first, grow a pure metal Ti layer with a thickness of 250nm, and the process parameters are as follows: sputtering power 30W, working pressure 0.25Pa, substrate heating temperature 250°C, substrate negative bias 0V; then, grow TiB 2 layer, TiB 2 It is a functional coating with a thickness of 2.25 μm. The process parameters are as follows: sputtering power 180W, working pressure 0.2Pa, substrate heating temperature 425°C, substrate negative bias 60V; the total thickness of the composite coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com