Photocatalysis reduction method and device for CO2 in flue gas in oxygen-enriched combustion power plant

A photocatalytic and CO2 technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of inability to utilize resources, environmental hazards, high cost, etc., and achieve low resistance, reduce CO2 emissions, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention.

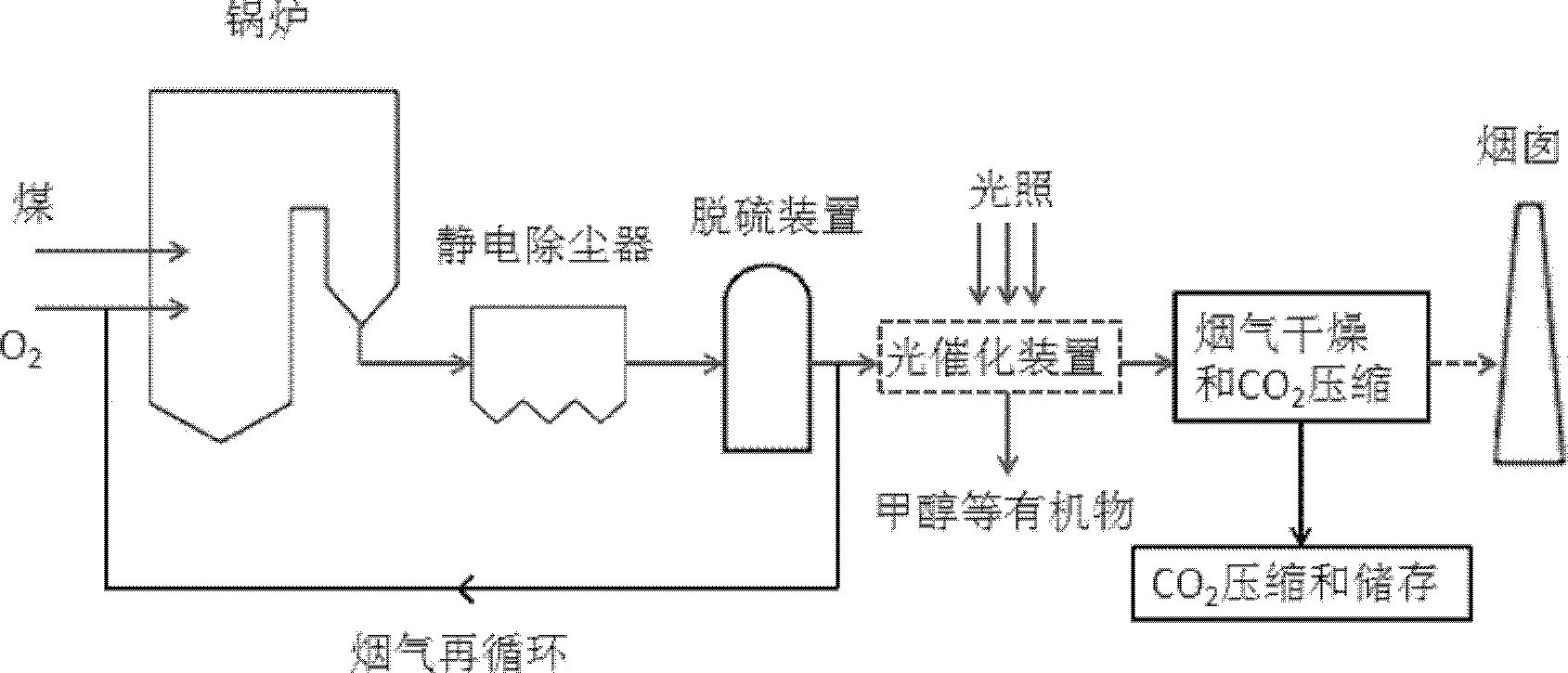

[0020] Such as figure 1 , flue gas drying and CO 2 Before the compression device, set a device that can reduce the high concentration of CO in the flue gas 2 A photocatalytic device for reducing organic substances such as methanol.

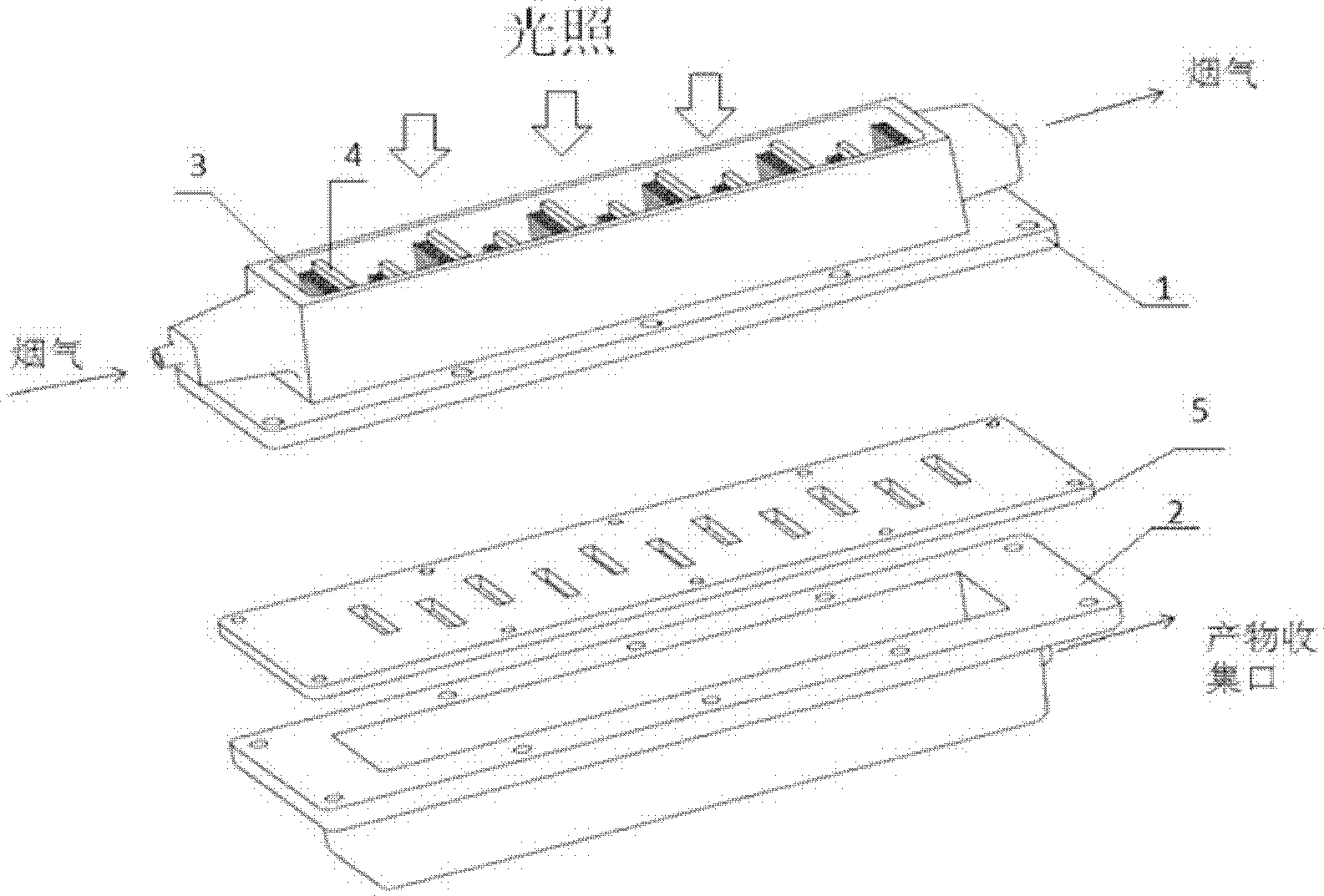

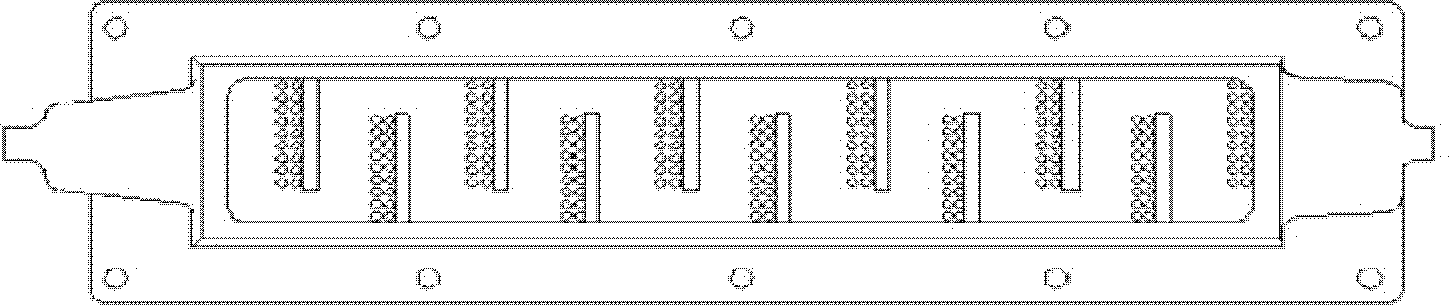

[0021] Such as figure 2 , a fiber optic photocatalytic device includes a reaction unit 1 and a product collection unit 2 . The reaction unit 1 includes a reaction chamber, the two ends of the reaction chamber are respectively provided with flue gas inlet and outlet, and the inside of the reaction chamber is equidistantly provided with a plurality of baffles 4 (see image 3 ), the optical fiber bundle 3 is arranged on the baffle plate 4 in a layered manner through the optical fiber holder, and the surface of each optical fiber is loaded with catalyst rare earth doped TiO 2 . The light source is injected from one end of the optical fiber layer th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com