Inorganic pollution resistance antibacterial reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane and inorganic technology, applied in the field of water treatment, can solve the problems of polyamide layer without substantial binding force, polyamide membrane binding force is not enough, easy to hydrolyze and fall off, etc., to improve the ability of anti-inorganic pollution, realize large-scale and Continuity, effect of low equipment operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Composite reverse osmosis membranes were prepared in the following steps:

[0019] (1) Solution preparation: Weigh 2.5g of polyvinyl alcohol 1499 and 1g of titanium dioxide powder, stir and dissolve in 1000g of water, then weigh 1.5g of maleic anhydride and add it to obtain a mixed functional solution.

[0020] (2) The basic reverse osmosis membrane is completely immersed in the mixed solution for 5 seconds, and then placed in an oven at 80° C. for 10 minutes to obtain an anti-pollution composite reverse osmosis membrane.

Embodiment 2

[0022] Composite reverse osmosis membranes were prepared in the following steps:

[0023] (1) Solution preparation: weigh 4g of polyvinyl alcohol 1799 and 0.5g of titanium dioxide powder, stir and dissolve in 1000g of water, then weigh 0.5g of glyoxal and add it to obtain a mixed functional solution.

[0024] (2) The basic reverse osmosis membrane is completely immersed in the mixed solution for 10 seconds, and then placed in an oven at 100°C for 8 minutes to obtain an anti-pollution composite reverse osmosis membrane.

Embodiment 3

[0026] Composite reverse osmosis membranes were prepared in the following steps:

[0027] (1) Solution preparation: Weigh 3g of polyvinyl alcohol 2699 and 0.2g of alumina powder, stir and dissolve in 1000g of water, then weigh 1.5g of glutaraldehyde and add it to obtain a mixed functional solution.

[0028] (2) The basic reverse osmosis membrane is completely immersed in the mixed solution for 10 seconds, and then placed in an oven at 100°C for 10 minutes to react to obtain an anti-pollution composite reverse osmosis membrane.

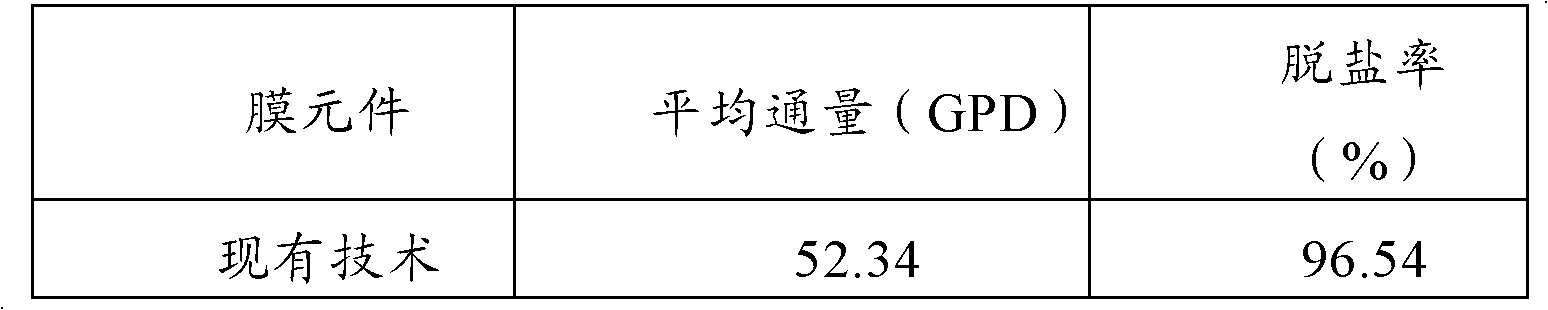

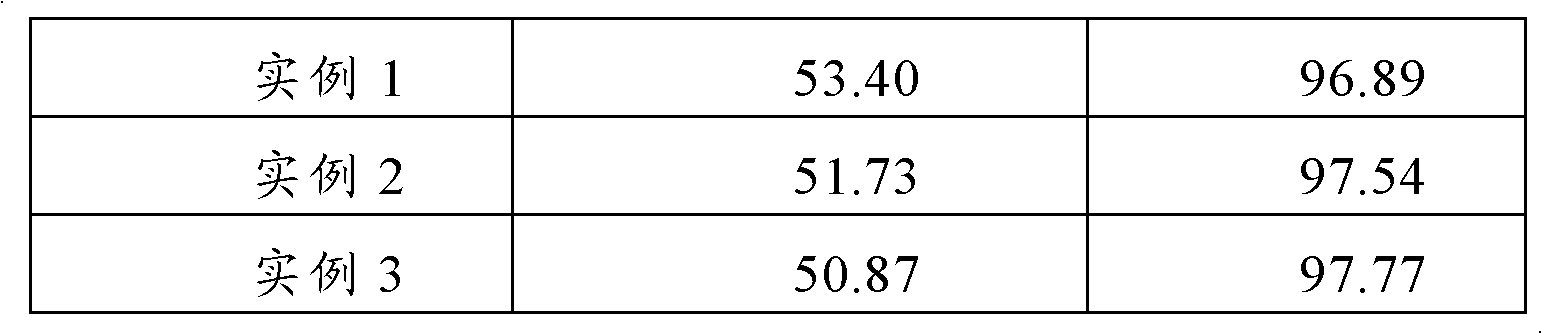

[0029] The flux and effective desalination rate of the diaphragm produced according to the above specific examples, rolled into a household membrane module and the spiral-wound membrane element in the prior art are shown in Table 1:

[0030] Table 1

[0031]

[0032]

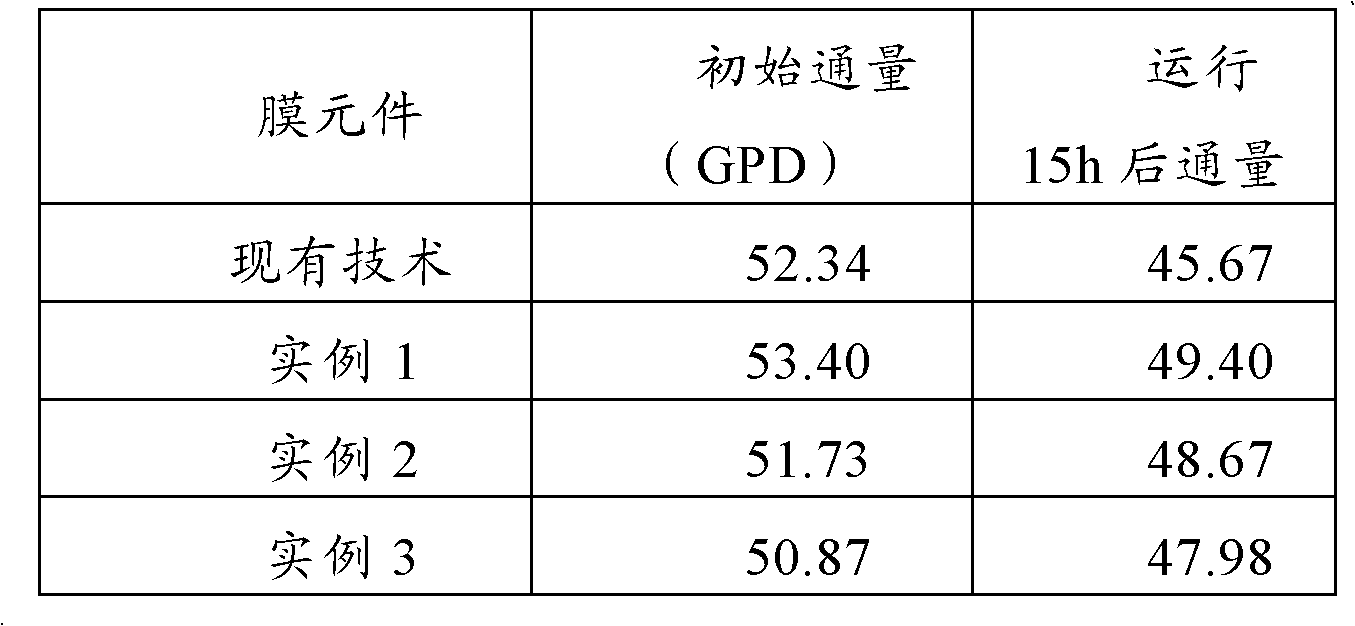

[0033] Table 2 is the comparison of the initial flux and the flux after running for 15 hours between the anti-fouling membrane module of the present invention and the spiral woun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com