Vanadium pentoxide (V2O5) material with large specific surface area and preparation method thereof

A technology of vanadium pentoxide and large specific surface area, applied in the field of V2O5 material and its preparation, can solve the problems of decreased electrochemical performance, complicated process and high energy consumption, and achieves the effects of improved material purity, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

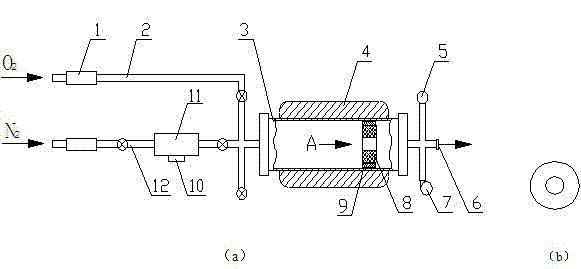

[0026] The method of the present invention is based on the chemical vapor deposition method to carry out the V-V according to the present invention 2 O 5 The specific steps for the synthesis of materials are as follows:

[0027] The first step is to configure the preparation system CVD corresponding to the chemical vapor deposition method before synthesis. see figure 1 , connect the quartz evaporator with a diameter of 10cm to the pipeline 12 of the preparation system through nitrogen, adopt a ring-shaped columnar quartz substrate 8, and clean the substrate 8 with acetone or alcohol, and place the substrate 8 in the furnace tube 3 Corresponding to the side of the air outlet 6, 50-60 cm away from the center of the furnace tube. Then take a certain amount of vanadyl acetylacetonate (VO(acac) 2 ) as a precursor into a quartz boat, and put the quartz boat into the evaporator 11.

[0028] In the second step, the CVD preparation system is sealed, and the furnace tube 3 is evacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com