Method for utilizing activated sludge, ozone and magnetic field to reduce sludge

A sludge reduction and activated sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as deterioration of effluent water quality, increase of effluent COD, nitrogen, and phosphorus , to achieve the effect of improving effluent water quality, VSS/SS, and improving the reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

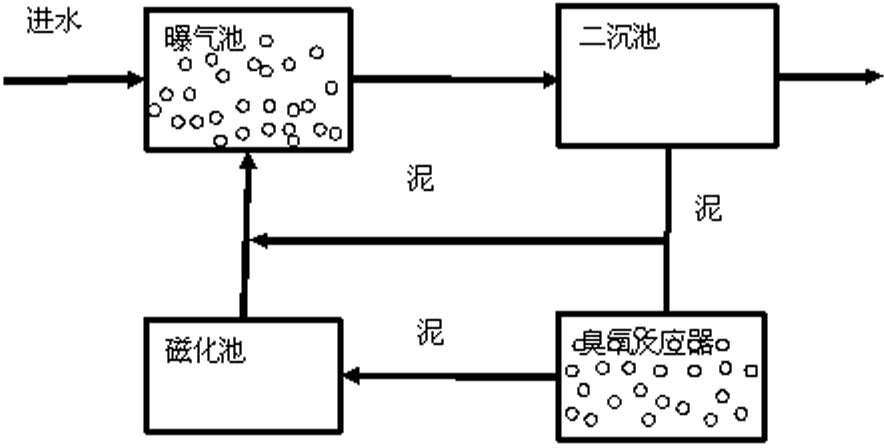

Image

Examples

Embodiment 1

[0023] Example 1: What this embodiment adopts is the activated sludge process and its improved process. The volume ratio of each reactor is aeration tank:secondary sedimentation tank:magnetization tank=20:8:1. The concentration of sludge in the aeration tank is 1-3g / l, the temperature in the aeration tank is kept at 20-40 degrees, the pH is kept at 6.8-7.5, and trace elements calcium, iron, magnesium, and cobalt are added to the aeration tank , Nickel, the addition amount is 0.08 mg / l, 0.08 mg / l, 0.08 mg / l, 0.04 mg / l, 0.04mg / l respectively, so that the concentration of trace elements iron, manganese, calcium, magnesium and sodium are kept at A certain concentration, the magnetic field strength of the magnetization pool is 50GS. There are 3 sets of experimental devices (marked as a, b, c). The three sets of devices are all connected to the activated sludge of the secondary settling tank of a sewage treatment plant, and the untreated sewage (COD is 250mg / l) is fed into the ...

Embodiment 2

[0026] Example 2:What this embodiment adopts is the activated sludge process and its improved process. The volume ratio of each reactor is aeration tank:secondary sedimentation tank:magnetization tank=20:8:1. The concentration of sludge in the aeration tank is 1-3g / l, the temperature in the aeration tank is kept at 20-40 degrees, the pH is kept at 6.8-7.5, and trace elements calcium, iron, magnesium, and cobalt are added to the aeration tank , Nickel, the addition amount is 0.08 mg / l, 0.08 mg / l, 0.08 mg / l, 0.04 mg / l, 0.04mg / l respectively, so that the concentration of trace elements iron, manganese, calcium, magnesium and sodium are kept at With a certain concentration, the magnetic field strength of the magnetization pool is 200GS. There are 3 sets of experimental devices (marked as a, b, c). The three sets of devices are all connected to the activated sludge of the secondary settling tank of a sewage treatment plant, and the untreated sewage (COD is 250mg / l) is fed into ...

Embodiment 3

[0029] Example 3: What this embodiment adopts is the activated sludge process and its improved process. The volume ratio of each reactor is aeration tank:secondary sedimentation tank:magnetization tank=20:8:1. The concentration of sludge in the aeration tank is 1-3g / l, the temperature in the aeration tank is kept at 20-40 degrees, the pH is kept at 6.8-7.5, and trace elements calcium, iron, magnesium, and cobalt are added to the aeration tank , Nickel, the addition amount is 0.08 mg / l, 0.08 mg / l, 0.08 mg / l, 0.04 mg / l, 0.04mg / l respectively, so that the concentration of trace elements iron, manganese, calcium, magnesium and sodium are kept at A certain concentration, the magnetic field strength of the magnetization pool is 500GS. There are 3 sets of experimental devices (marked as a, b, c). The three sets of devices are all connected to the activated sludge of the secondary settling tank of a sewage treatment plant, and the untreated sewage (COD is 250mg / l) is fed into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com