Water-soluble hot melt adhesive for wafer bonding in crystal processing process and preparation method thereof

A water-soluble hot-melt adhesive and processing technology, applied in stone processing equipment, adhesives, manufacturing tools, etc., can solve problems such as environmental pollution, high bonding strength, and restricted development, and achieve the effect of no pollution to the environment and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

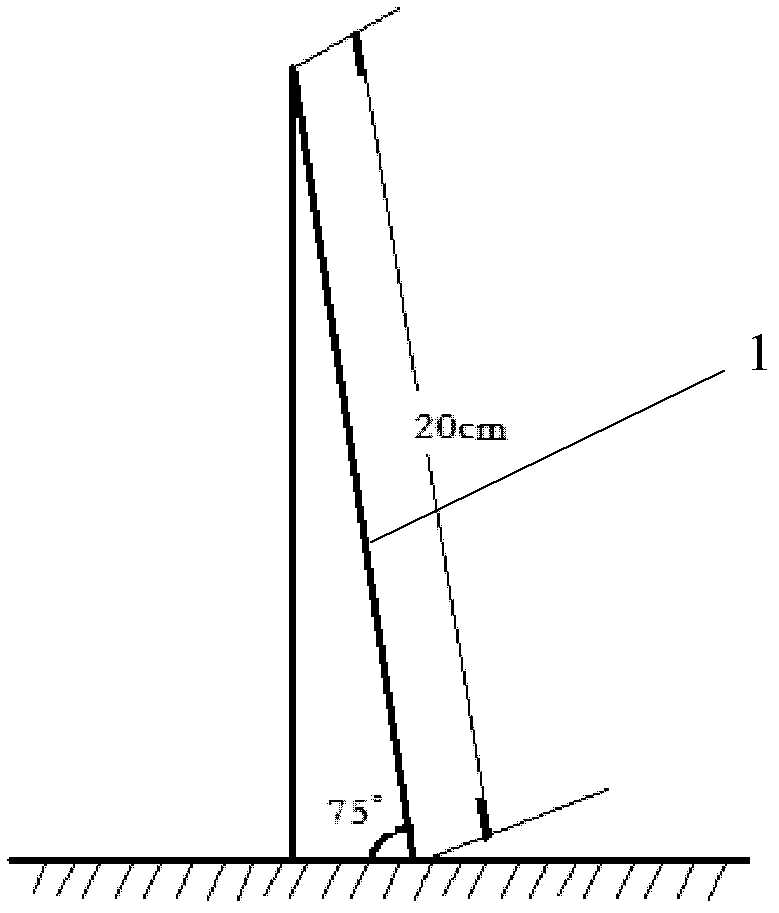

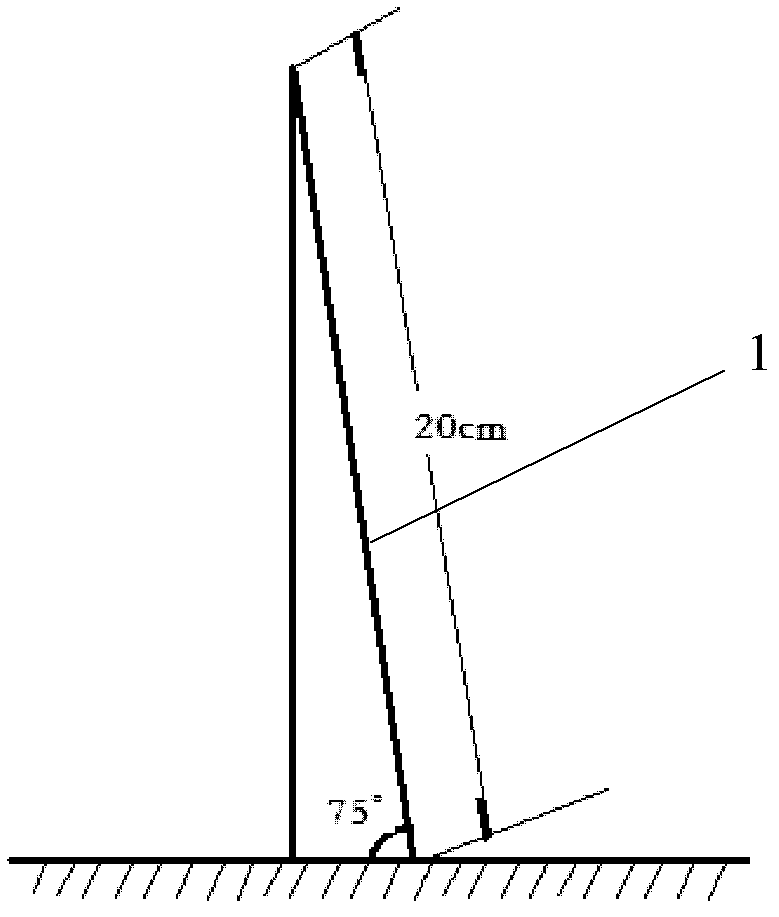

Embodiment 1

[0020] With the water-soluble polyester of 100 parts by weight (water-soluble polyester is the DX-70 type water-soluble polyester that Yichang Jiuwan Polyester Material Co., Ltd. produces), the glyceryl monostearate of 15 parts by weight is added to belt In a heated mixer, heat to 150°C, stir well to make the material mix evenly (about 30min), then discharge and cool to shape. The fluidity of the hot melt adhesive is 8min / (10cm, 150°C, g) (a metal plate with an elevation angle of 75°), that is, at 150°C, 1g of the above hot melt adhesive flows 10cm on a stainless steel plate with an elevation angle of 75° The time is 8 minutes; the dissolution time of the adhesive in boiling water is about 5 minutes; the bonding strength can meet the requirements of machining, that is, it will not crack during machining. Coat on the wafer surface with the hot melt adhesive of embodiment 1, pressurize and cool and implement bonding; After bonding, carry out mechanical processing; After mechanic...

Embodiment 2

[0022] With the water-soluble polyester of 85 parts by weight (water-soluble polyester is the DX-70 type water-soluble polyester that Yichang Jiuwan Polyester Material Co., Ltd. produces), the rosin of 15 parts by weight or modified rosin, 15 parts by weight Add a few glyceryl monostearate into a mixer with heating, heat to 150°C, stir well to make the material mix uniformly (about 30min), discharge, and cool to form. The fluidity of the hot melt adhesive is 5min / (10cm, 150°C, g) (a metal plate with an elevation angle of 75°), that is, at 150°C, 1g of the above hot melt adhesive flows 10cm on a stainless steel plate with an elevation angle of 75° The time is 8 minutes; the dissolution time of the adhesive in boiling water is about 5 minutes; the bonding strength can meet the requirements of machining, that is, it will not crack during machining. Coat the hot melt adhesive of embodiment 2 on the wafer surface, pressurize and cool to implement bonding; after bonding, carry out m...

Embodiment 3

[0024] With the water-soluble polyester of 80 parts by weight (water-soluble polyester is the DX-70 type water-soluble polyester that Yichang Jiuwan Polyester Material Co., Ltd. produces), the rosin of 20 parts by weight or modified rosin, 15 parts by weight Add a few glyceryl monostearate into a mixer with heating, heat to 150°C, stir well to make the material mix uniformly (about 30min), discharge, and cool to form. The fluidity of the hot melt adhesive is 4min / (10cm, 150°C, g) (a metal plate with an elevation angle of 75°), that is, at 150°C, 1g of the above hot melt adhesive flows 10cm on a stainless steel plate with an elevation angle of 75° The time is 8 minutes; the dissolution time of the adhesive in boiling water is about 5 minutes; the bonding strength can meet the requirements of machining, that is, it will not crack during machining. Coat the hot melt adhesive of embodiment 3 on the wafer surface, pressurize and cool to implement bonding; after bonding, carry out m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com