Method for producing glutathione by fermentation of recombinant Escherichia coli

A technology for recombining Escherichia coli and glutathione, which is applied in the field of bioengineering, can solve the problems of long production cycle and low production level per unit cell, achieve high GSH synthesis ability, short cell culture time and production cycle, and respond fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Gene cloning of bifunctional glutathione synthetase.

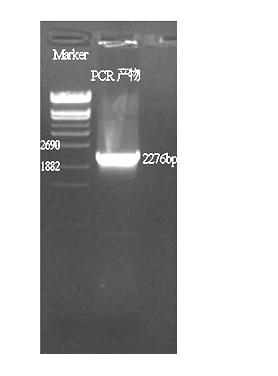

[0024] Streptococcus thermophilus genomic DNA was used as a template, and primers CGGCGAATTCACGATGACATTAAACCA and GGCAAGCTTTTAAGTTTGACCAGCCACT were used for PCR amplification to obtain a DNA fragment with a length of about 2.3kb (the gene sequence number is GU138096). Electrophoresis of PCR products as shown in figure 1 shown.

Embodiment 2

[0025] Example 2: Construction of recombinant Escherichia coli expressing exogenous bifunctional glutathione synthetase.

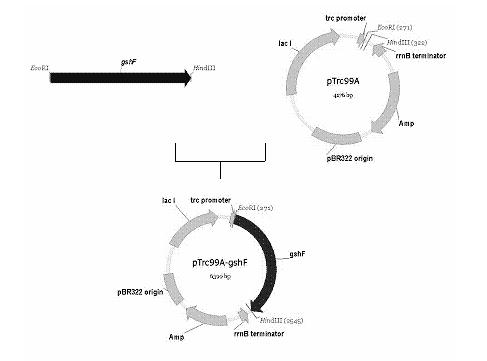

[0026] The gshF gene fragment amplified by PCR in Example 1 and the expression vector pTrc99A were digested overnight at 37°C with restriction endonucleases EcoRI and Hind III, and the target band was recovered by electrophoresis. The ligation reaction was carried out at ℃ for 12 hours to obtain the pTrc99A-gshF plasmid. And transform Escherichia coli JM109 to obtain recombinant Escherichia coli JM109 / pTrc99A-gshF ( figure 2 ).

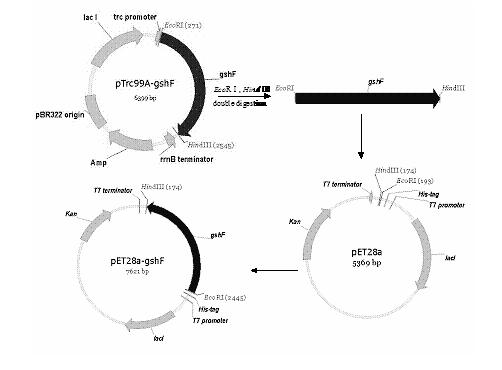

[0027] Plasmid pTrc99A-gshF and plasmid pET28a were digested with EcoRI and Hind III overnight at 37°C, recovered by electrophoresis, and the digested target fragment gshF was ligated with the vector fragment pET28a, overnight at 16°C to obtain pET28a-gshF. The recombinant plasmid pET28a-gshF was transformed into Escherichia coli BL21 to obtain recombinant Escherichia coli BL21 / pET28a-gshF ( image 3 ).

Embodiment 3

[0028] Example 3: Fermentation of self-inducing medium.

[0029] The strain used is BL21 / pET28a-gshF, constructed by the method described in Example 2. Inoculate the overnight cultured seed culture medium with 5% inoculum into 3L compound medium (peptone 10 g / L, yeast extract 5 g / L, 50 mM phosphate buffer pH 7.6, ammonium chloride 50 mM , sodium sulfate 5 mM, magnesium sulfate 2 mM, 0.2 mL trace elements, glycerol 20 g / L, glucose 0.6 g / L, α-lactose 2 g / L) in a 5L fermenter, the fermentation temperature was 30°C, and the Air flow and speed, maintain dissolved oxygen above 20%. Add ammonia water to control pH 7.0. When the cell OD is 30, add three kinds of amino acids and continue to cultivate for 2 hours. The glutathione content is 3.20 g / L, the unit cell production level is 240 mg / g dry cell, and the production intensity is 165 mg / L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com