Preparation method and application of transparent titanium dioxide nanotube film

A technology of titanium dioxide and nanotubes, which is applied in the field of nanometers, can solve the problems of long release time, reduced film thickness, high energy consumption, etc., and achieves the effects of simple preparation method, slow dissolution rate and good film stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a transparent titanium dioxide nanotube film and its application in a light-responsive artificial ion channel. The preparation method includes the following steps:

[0020] The first step, an anodizing:

[0021] The cleaned and dried titanium sheet is anodized in an organic fluorine-containing electrolyte solution A to obtain a titanium dioxide nanotube array. The component of described organic fluorine-containing electrolytic solution A is 0.25g NH 4 F, 2ml H 2 O and 100ml ethylene glycol. The anodic oxidation uses the platinum sheet as the cathode and the titanium sheet as the anode, and the anodic oxidation condition is in a constant temperature water bath at 20-30°C, with a voltage of 40-60V, for 1 hour. The cleaning refers to cleaning with acetone, absolute ethanol and deionized water successively and blowing dry.

[0022] The second step, secondary anodizing:

[0023] The titanium sheet after primary anodic oxidat...

Embodiment 1

[0030] Embodiment one: The preparation of the titanium dioxide self-supporting film transparent at both ends, the specific steps are as follows:

[0031]The first step, primary anodic oxidation: clean and dry the titanium sheet with acetone, absolute ethanol and deionized water in sequence, use the platinum sheet as the cathode, and the titanium sheet as the anode, with a voltage of 40V, in the organic fluorine-containing electrolyte A, In a constant temperature water bath at 20-30°C, a titanium dioxide nanotube film is grown through anodic oxidation. The organic fluorine-containing electrolyte A component is 0.25g NH 4 F, 2mlH 2 O and 100ml ethylene glycol.

[0032] The second step, secondary anodic oxidation: ultrasonically clean the titanium sheet that has been anodized once in 1M HCl solution and deionized water for 5-10 minutes respectively, and after drying, continue to put the titanium sheet into the organic fluorine-containing electrolyte A. Anodize in a constant ...

Embodiment 2

[0035] Embodiment two: Preparation of self-supporting films of titanium dioxide through both ends;

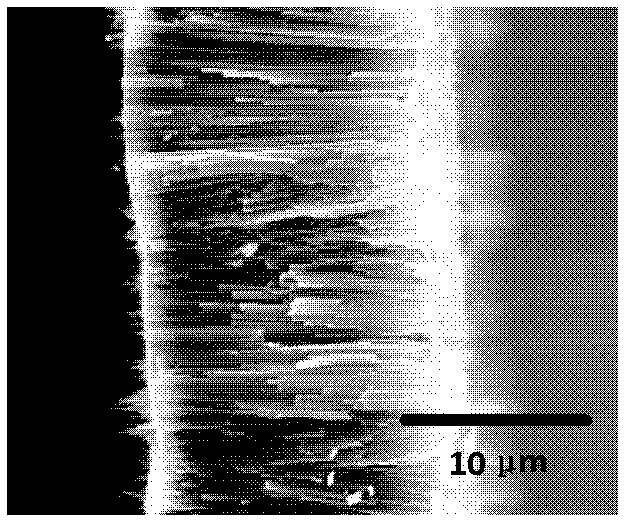

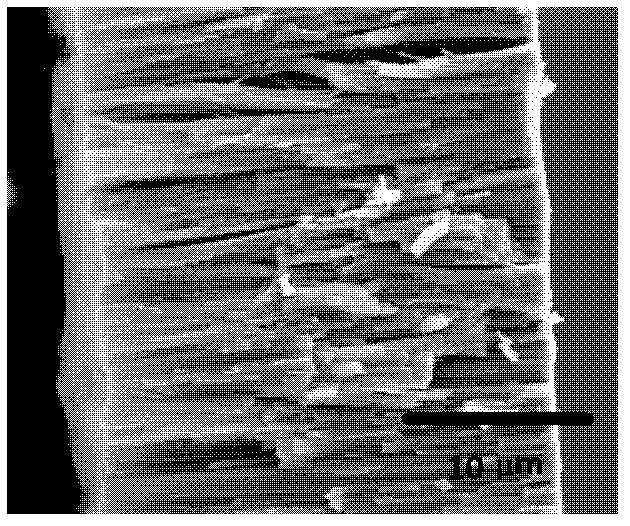

[0036] The other steps implemented in this embodiment are the same as in Embodiment 1, the difference is that the primary anodizing voltage is 60V, and a low-temperature annealing step is also included between the second step and the third step, specifically: titanium sheet anodizing After 5 hours, wash with isopropanol, blow dry, and then anneal at 200°C for 3 hours, and then carry out the third step of high-pressure anodic oxidation stripping. Depend on Figure 2a It can be seen that the surface of the film is very smooth, the nozzle is not corroded, and the thickness of the film reaches 24 μm; Figure 2b is a photograph of the obtained self-supporting film, and it can be seen that the film is quite intact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com