Self-cleaning cloth with decontamination and anti-bacteria functions in the sun and manufacturing method thereof

A production method and sunlight technology, applied in textiles, papermaking, fiber processing and other directions, can solve the problems of increased process cost, high heat treatment temperature, weak decontamination and antibacterial effect, etc., and achieve the effect of low production cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

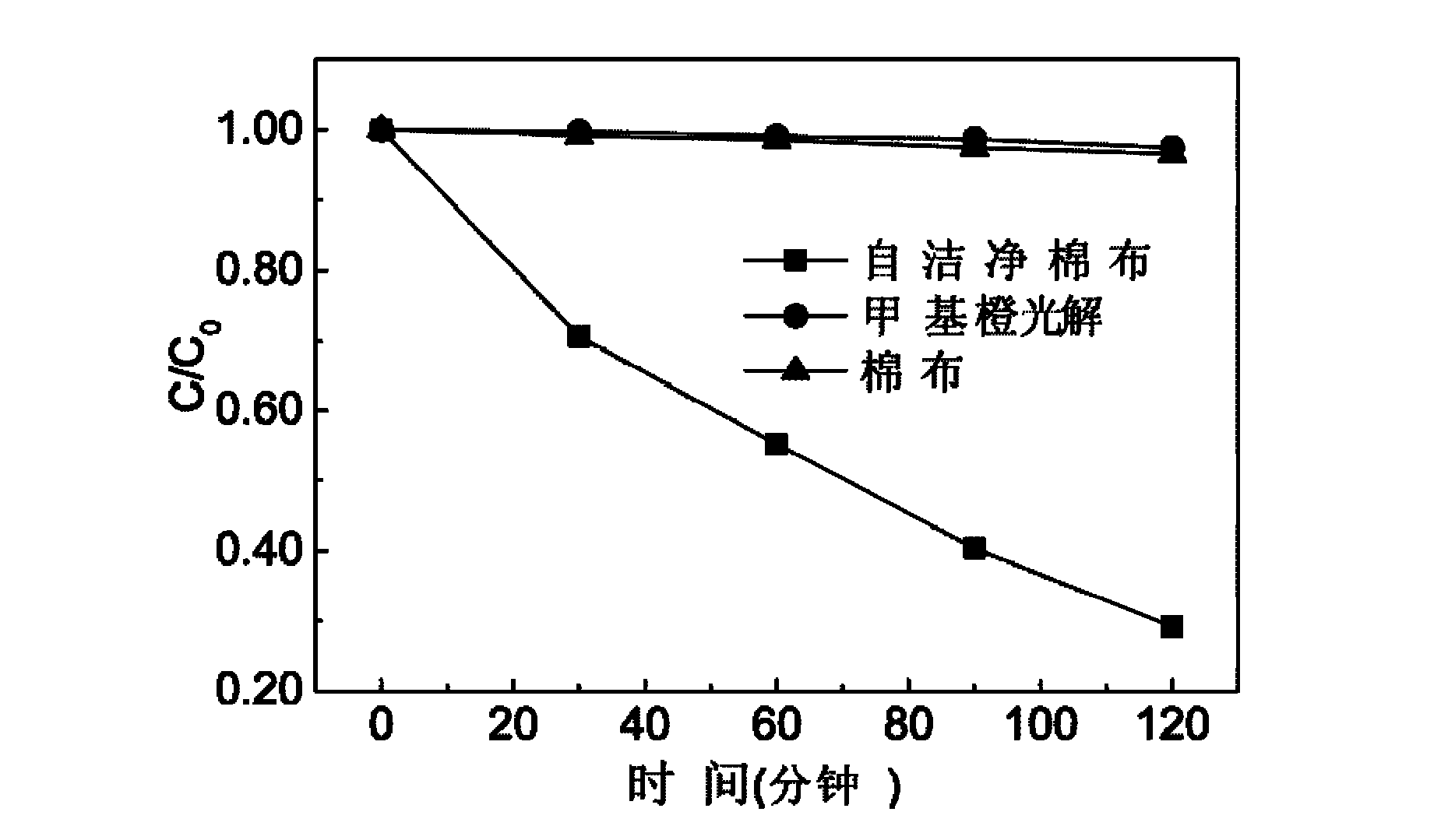

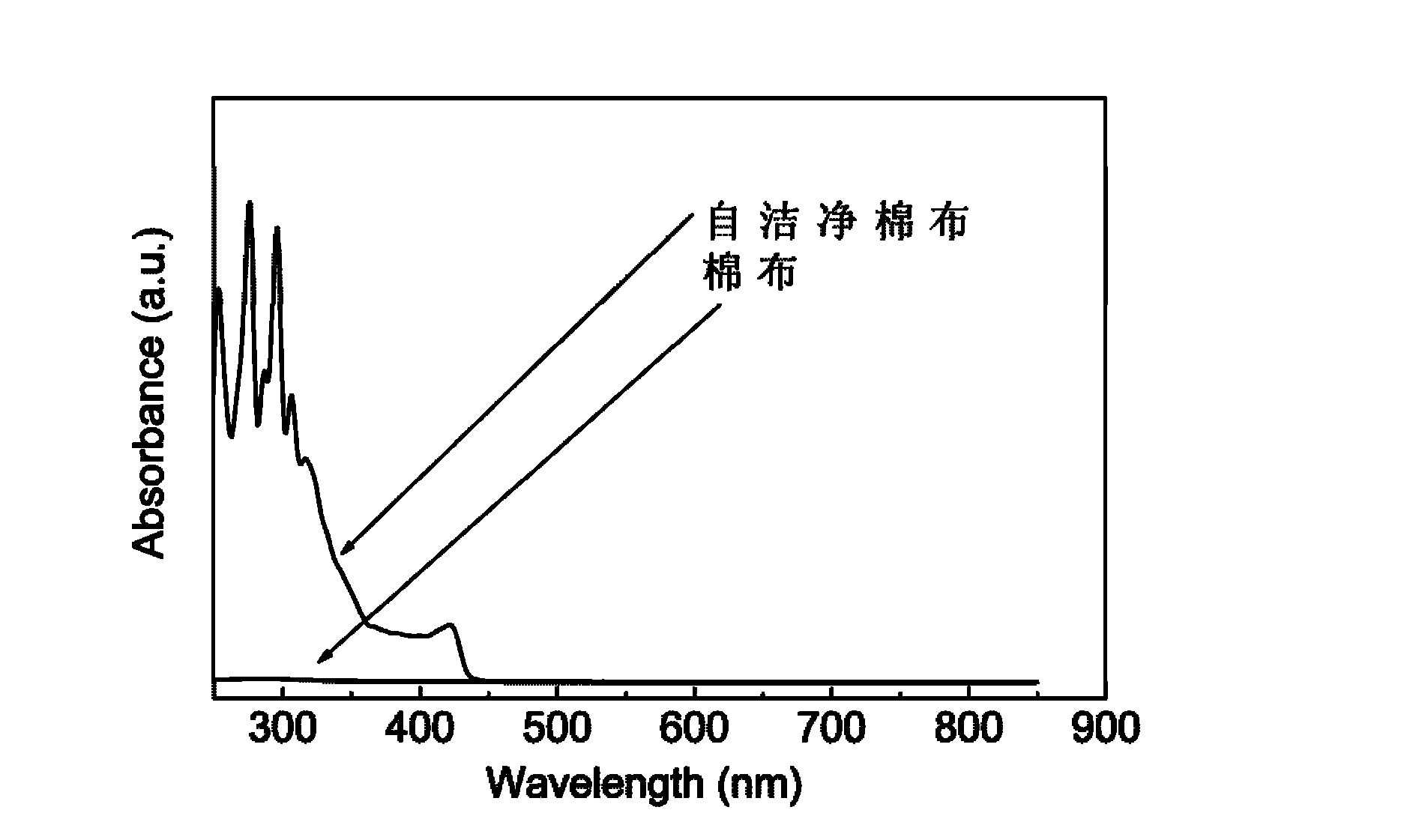

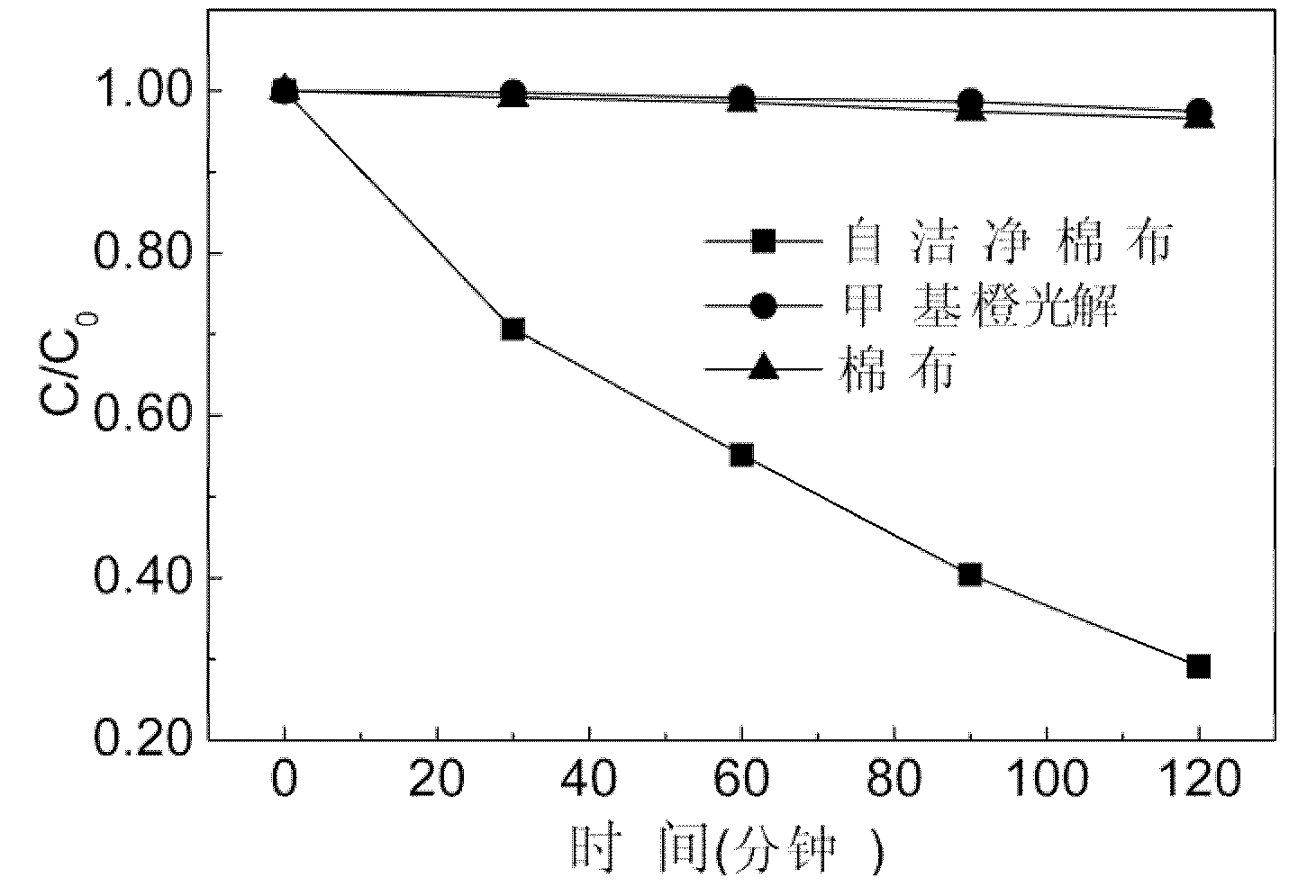

[0024] (1) Take 100 ml of titanium dioxide sol with a concentration of 20 g / L, add 1 ml of acetylacetone and 2 ml of trimethylamine, and react under reflux at 120 degrees for 12 hours to obtain a modified titanium dioxide sol. (2) A piece of cleaned cotton cloth (size 4 cm × 4 cm), immersed in the modified titanium dioxide sol for 30 seconds, taken out, pressed and rolled under a pressure of 5 kg / cm2, and then dipped and rolled once. The cloth is soaked in hot water at 95 degrees for 30 minutes, and the water is changed 3 times during this period to obtain a stabilized modified titanium dioxide coating. (3) preparation concentration is 50 milliliters of silver nitrates of 0.01 mol / liter, and 50 milliliters of potassium bromide of 0.005 mol / liter and 0.005 mol / liter of potassium chloride mixed solution 50 milliliters, the cotton cloth after the treatment of modified titanium dioxide is immersed in nitric acid earlier Soak in silver solution for 300 seconds, then immerse in pota...

Embodiment 2

[0028] (1) Take 100 ml of titanium dioxide sol with a concentration of 50 g / L, add 2 ml of acetylacetone and 3 ml of triethylamine, and react under reflux at 110 degrees for 24 hours to obtain a modified titanium dioxide sol. (2) A piece of cleaned cotton cloth (size 5 cm × 5 cm), immersed in the modified titanium dioxide sol for 60 seconds, taken out and rolled under a pressure of 2.5 kg / cm2, and then dipped-rolled twice, Soak the cloth in 80-degree hot water for 20 minutes, and change the water twice during this period to obtain a stabilized modified titanium dioxide coating. (3) Preparation concentration is 100 milliliters of silver ammonia solution of 0.05 mol / liter, and 100 milliliters of mixed solution of 0.02 mol / liter potassium iodide and 0.03 mol / liter potassium bromide, soaks the cotton cloth after the modified titanium dioxide treatment earlier into potassium iodide and bromine Potassium chloride mixed solution for 60 seconds, then immersed in silver ammonia solution ...

Embodiment 3

[0030] (1) Take 50 ml of titanium dioxide sol with a concentration of 10 g / L, add 1 ml of citric acid and 3 ml of diethylamine, and react under reflux at 130 degrees for 48 hours to obtain a modified titanium dioxide sol. (2) A piece of cleaned woolen cloth (size 5 cm × 5 cm), immersed in the modified titanium dioxide sol for 120 seconds, taken out, pressed and rolled under a pressure of 1.5 kg / cm2, and then dipped and rolled three times, Soak the cloth in 100-degree hot water for 50 minutes, and change the water 4 times during the period to obtain a stabilized modified titanium dioxide coating. (3) preparation concentration is 60 milliliters of silver-ammonia solutions of 0.005 mol / liter, and 60 milliliters of potassium chloride mixed solutions of 0.0025 mol / liter potassium bromide and 0.0025 mol / liter, the wool cloth after the modified titanium dioxide treatment is first Immerse in silver ammonia solution for 120 seconds, then immerse in potassium bromide solution for 120 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com