Method for detecting impurity components in alpha-alumina

A detection method, aluminum oxide technology, applied in the field of glass manufacturing, can solve the problems of unreliable ICP detection results, low efficiency, high power cost, etc., and achieve the effect of avoiding poor atomization effect, saving power cost and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

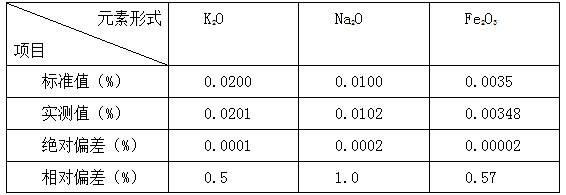

Image

Examples

Embodiment 1

[0031] (1) Weigh 0.1g of alumina sample into 1# and 2# digestion tanks, then add 9ml of concentrated phosphoric acid, 6ml of concentrated sulfuric acid, 1ml of concentrated hydrochloric acid, and shake carefully. Do sample blank experiment in 3#, 4#, 5#, 6# digestion tanks, that is, only add 9ml concentrated phosphoric acid, 6ml concentrated sulfuric acid, 1ml concentrated hydrochloric acid, shake carefully.

[0032] (2) Put the digestion tanks in the microwave digestion furnace, so that the 6 digestion tanks are evenly distributed in the furnace, and the angle between every two digestion tanks is 60°.

[0033] (3) Start the microwave digestion oven, set the temperature curve program to 10min and raise the temperature to 225°C, keep at 225°C for 35min, and the digestion process will end automatically.

[0034] (4) Take out the digestion tank carefully, after cooling for 5 minutes, carefully open the air vent to release the pressure, then fully open the digestion tank, the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com