Method for producing gold nanoarray ultramicroelectrode

An ultra-micro electrode, gold nanotechnology, applied in the direction of material electrochemical variables, etc., can solve problems such as limiting the application of gold nanostructure arrays, and achieve the effects of low cost, low cost replacement, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for manufacturing gold nano-array ultramicroelectrodes, the method comprises the following steps:

[0022] (1) Add chloroauric acid to BMIM[PF 6 ] In the ionic liquid, control the concentration of chloroauric acid to be 10mmol / L, after dissolving, add formamide, after fully mixing with a vortex oscillator, this solution is transferred in the 10ml test tube, the oven temperature is adjusted to 95 degrees, and the reaction is 22 Remove after hours and let cool. The supernatant was poured out, and a red precipitate was obtained after several washes with acetone. Vacuum-dried to obtain a red product powder, which was stored in a desiccator.

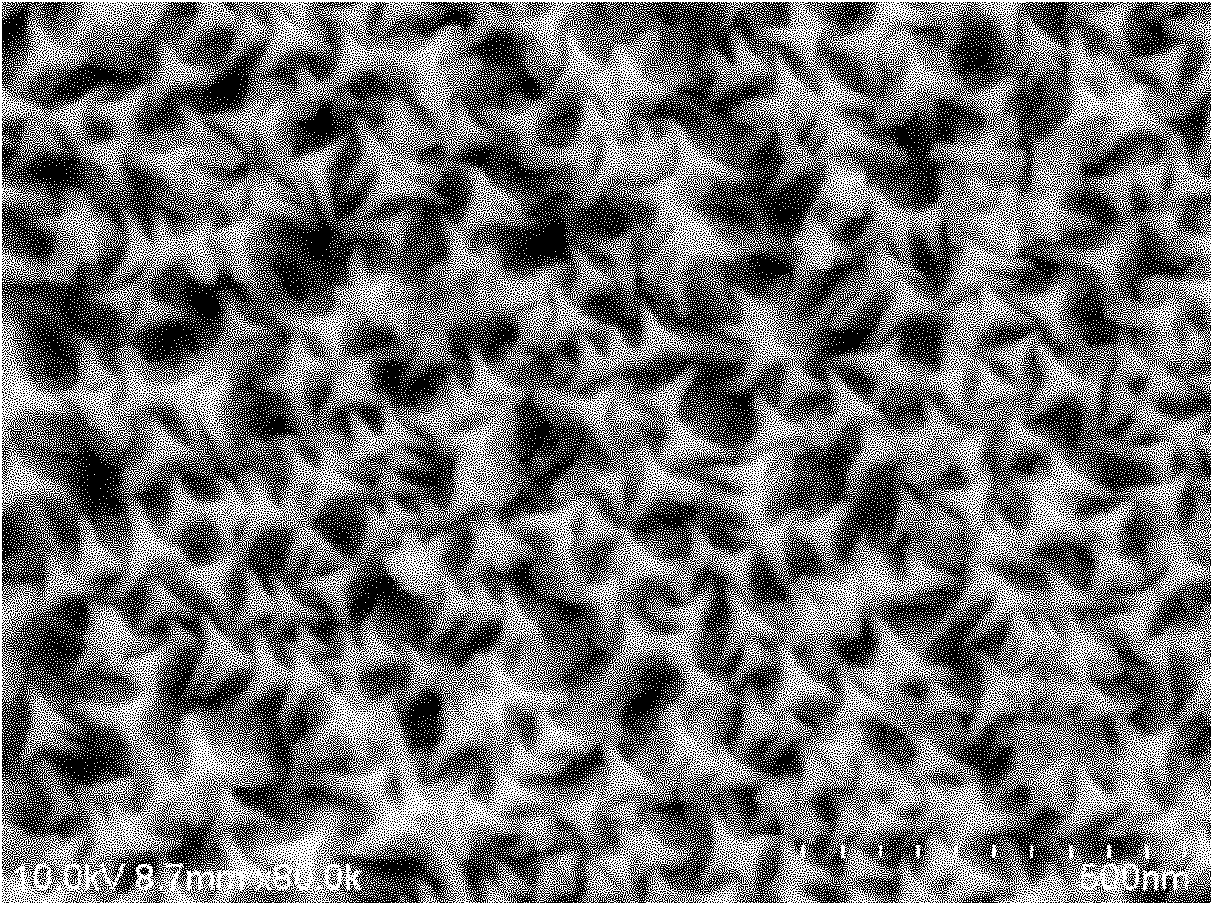

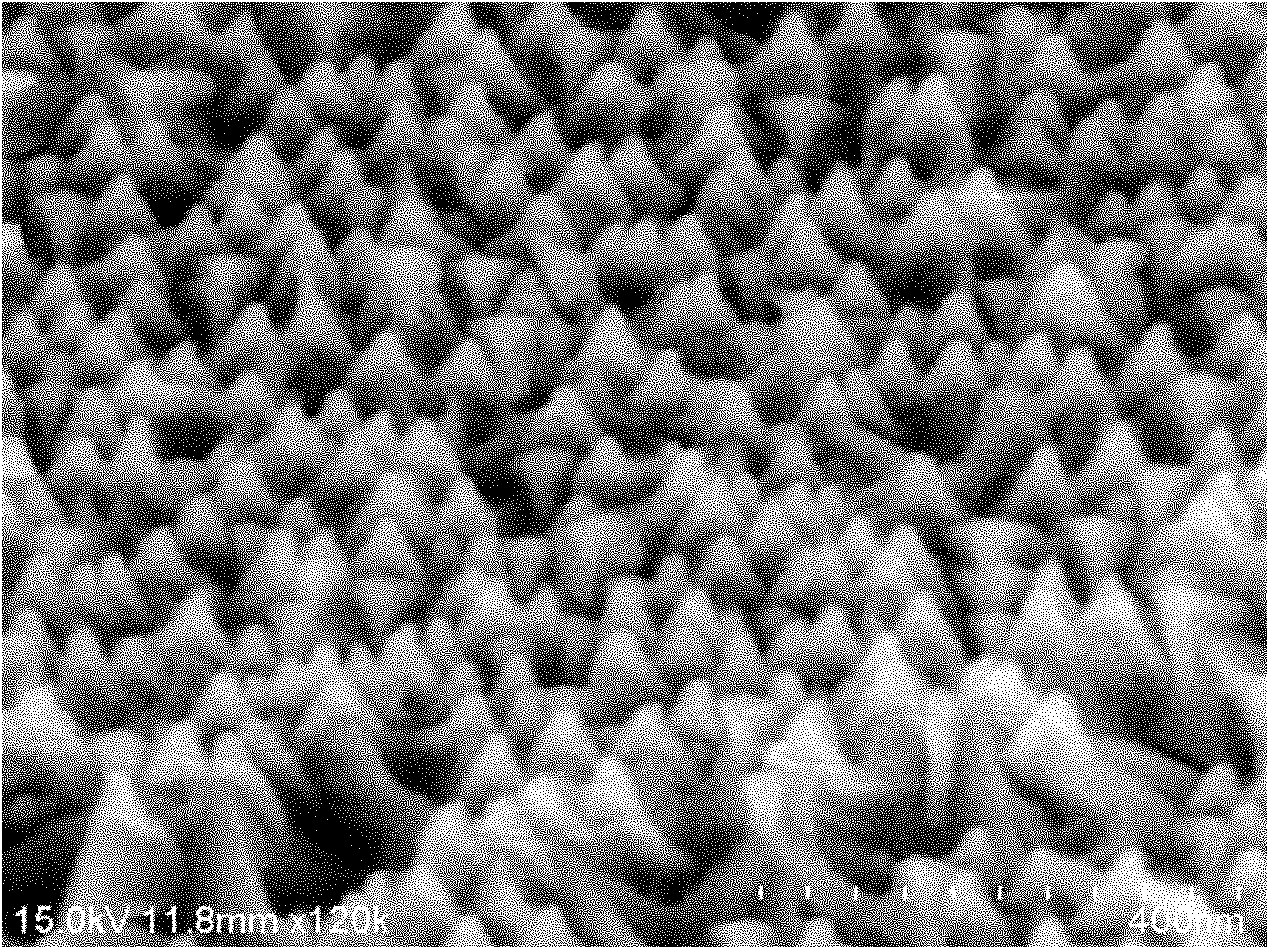

[0023] The powder of the product can be redispersed into 99% ethanol or secondary water. After ultrasonically assisted dispersion, quickly use a 10μl pipette to pipette an appropriate amount of product dispersion, drop-coat it on a silicon wafer, and place it in a vacuum oven for Scanning electron microscopy characterizatio...

Embodiment 2

[0027] A method for manufacturing gold nano-array ultramicroelectrodes, the method comprises the following steps:

[0028] (1) Preparation of gold microsheets with gold nanocone arrays on the surface: adding chloroauric acid to BMIM[PF 6 ] in the ionic liquid, control the concentration of chloroauric acid to be 8mmol / L, after dissolving, add formamide, BMIM[PF 6 ] The volume ratio of ionic liquid to formamide is 0.9. After fully mixing with a vortex oscillator, transfer the solution into a 10ml test tube, place it in an oven, control the temperature at 90°C, and the reaction time is 24h. The supernatant was poured out, washed several times with acetone to obtain a red precipitate product, and dried in vacuum to obtain gold microsheets with gold nanocone arrays on the surface. Trident sampan-shaped gold nanocones, stored in a desiccator;

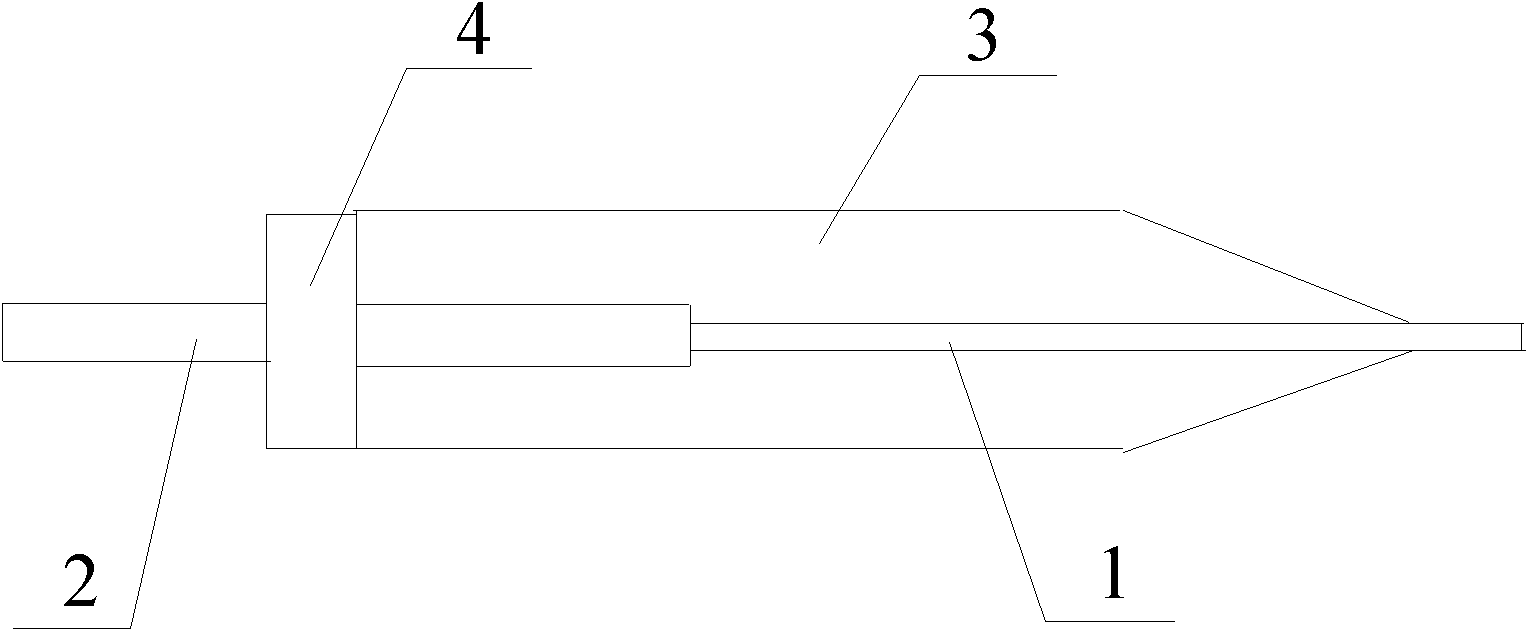

[0029] (2) Assembling and making of gold nanocone array ultramicroelectrodes: the gold microsheet with the gold nanocone array on the surf...

Embodiment 3

[0031] A method for manufacturing gold nano-array ultramicroelectrodes, the method comprises the following steps:

[0032] (1) Preparation of gold microsheets with gold nanocone arrays on the surface: adding chloroauric acid to BMIM[PF 6 ] in the ionic liquid, control the concentration of chloroauric acid to be 12mmol / L, after dissolving, add formamide, BMIM[PF 6] The volume ratio of the ionic liquid to formamide is 1.1. After fully mixing with a vortex oscillator, transfer the solution to a 10ml test tube, place it in an oven, control the temperature at 100°C, and take the reaction time for 20h. After cooling, the supernatant was poured out, washed several times with acetone to obtain a red precipitate product, and dried in vacuum to obtain gold microsheets with gold nanocone arrays on the surface. 100nm, trident-shaped gold nanocones stored in a desiccator;

[0033] (2) Assembly and manufacture of gold nanocone array ultramicroelectrodes: the gold microsheet with the gold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com