Method for preparing TiC-TiO2 core-shell type nanometer material

A nanomaterial, core-shell technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of high cost, long process, complex process, etc., achieve stable quality, reduce load, and increase catalytic surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

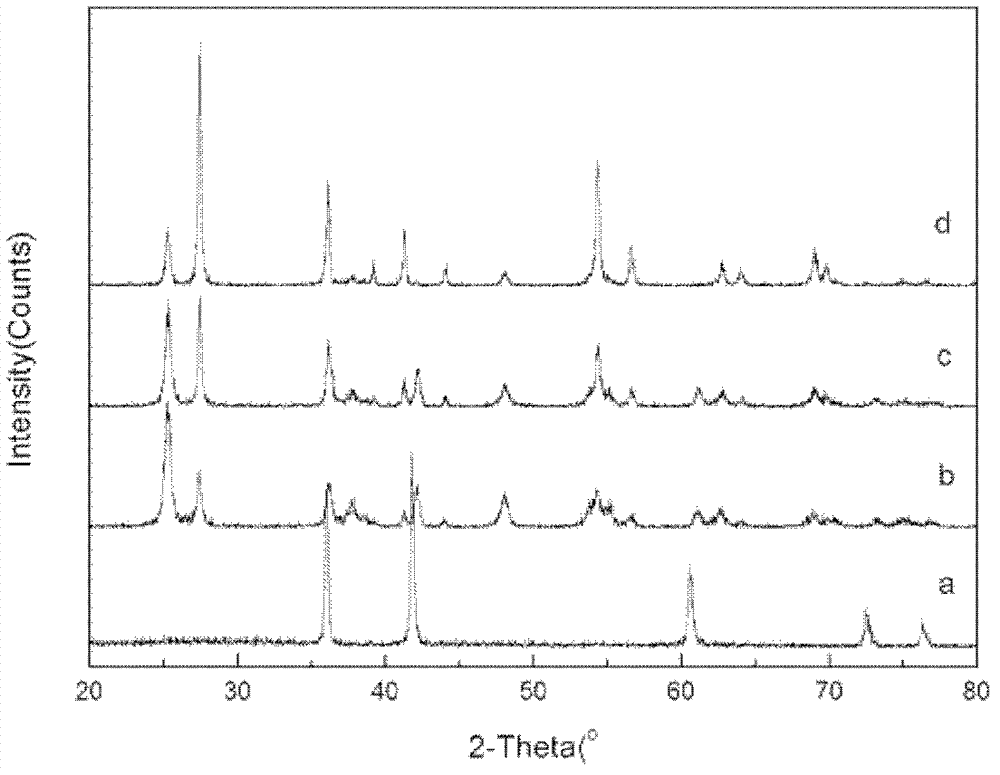

Embodiment 1

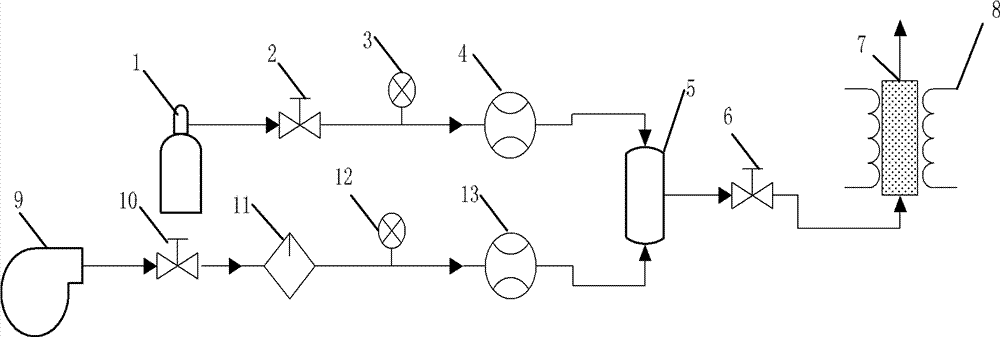

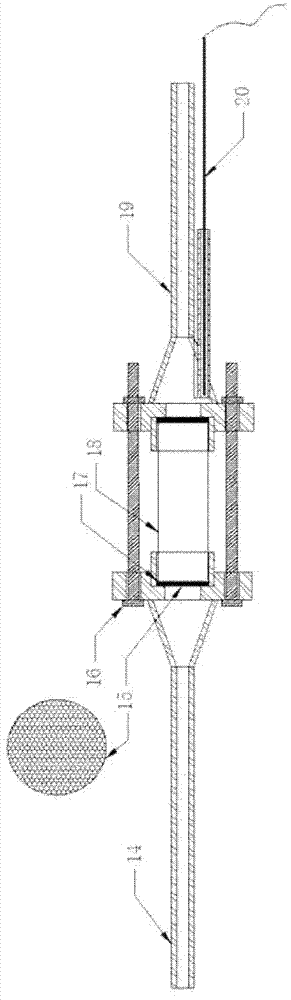

[0043] 1) Ingredients: uniformly mix an appropriate amount of TiC nanoparticles (produced by Aldrich, particle size 20-100nm) and potassium carbonate powder of the same quality, and then put it into the reactor; the oxidant is air.

[0044] 2) Reaction conditions: the fluidized bed reactor adopts a quartz glass tube with an outer diameter of 14mm, an inner diameter of 10mm, and a length of 30mm; the pressure of air and nitrogen is adjusted to 0.03MPa, the flow rate of air is 100ml / min, and the flow rate of nitrogen is 200ml / min min; the reaction time is 3 min, and the reaction temperatures are controlled at 610°C, 650°C and 690°C, respectively.

[0045] 3) Heating up: Before the reaction, pass nitrogen gas, discharge the air in the pipe, close the air valve, use the temperature control system to control the reaction temperature, and use a thermocouple to monitor the temperature of the gas at the outlet of the reactor.

[0046] 4) Reaction: When the temperature rises to the pre...

Embodiment 2

[0056] 1) Ingredients: uniformly mix an appropriate amount of TiC nanoparticles and sodium bicarbonate powder of the same quality, and then put them into the reactor.

[0057] 2) Reaction conditions: The fluidized bed reactor adopts a quartz glass tube with an outer diameter of 14mm, an inner diameter of 10mm, and a length of 30mm; the pressure of air and nitrogen is adjusted to 0.03MPa, the reaction time is 3min, and the reaction temperature is 610°C. The flow rate ratio is 100ml / min: 200ml / min and 100ml / min: 400ml / min;

[0058] 3) Heating: Before the reaction, pass nitrogen gas to discharge the air in the reactor, close the air valve, use the temperature control system to control the reaction temperature, and use an external thermocouple to monitor the temperature in the reactor.

[0059] 4) Reaction: When the temperature rises to 610°C, air is introduced, and the reaction time is 3 minutes. After the reaction is completed, the air valve is closed, and nitrogen gas is contin...

Embodiment 3

[0063] 1) Ingredients: uniformly mix appropriate amount of TiC nanoparticles and potassium carbonate powder of the same quality, and then put them into the reactor.

[0064] 2) Reaction conditions: The fluidized bed reactor adopts a quartz glass tube with a straight outer diameter of 14mm, an inner diameter of 10mm, and a length of 30mm; the pressure of air and nitrogen is adjusted to 0.03MPa, the flow rate of air is 100ml / min, and the flow rate of nitrogen The reaction temperature is 200ml / min; the reaction temperature is 610°C, and the reaction time is 3min, 4min, 5min.

[0065] 3) Heating up: Before the reaction, pass nitrogen gas, discharge the air in the pipe, close the air valve, use the temperature control system to control the reaction temperature, and use a thermocouple to monitor the temperature of the gas at the outlet of the reactor.

[0066] 4) Reaction: When the temperature rises to 610°C, air is introduced, and the reaction time is 3 minutes. After the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com