Porous glass ceramic material, preparation method and prepared metamaterial substrate

A technology of porous glass ceramics and substrates, which can be applied to electrical components, antennas, etc., can solve problems such as limited effects, and achieve the effects of low dielectric constant, low loss, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

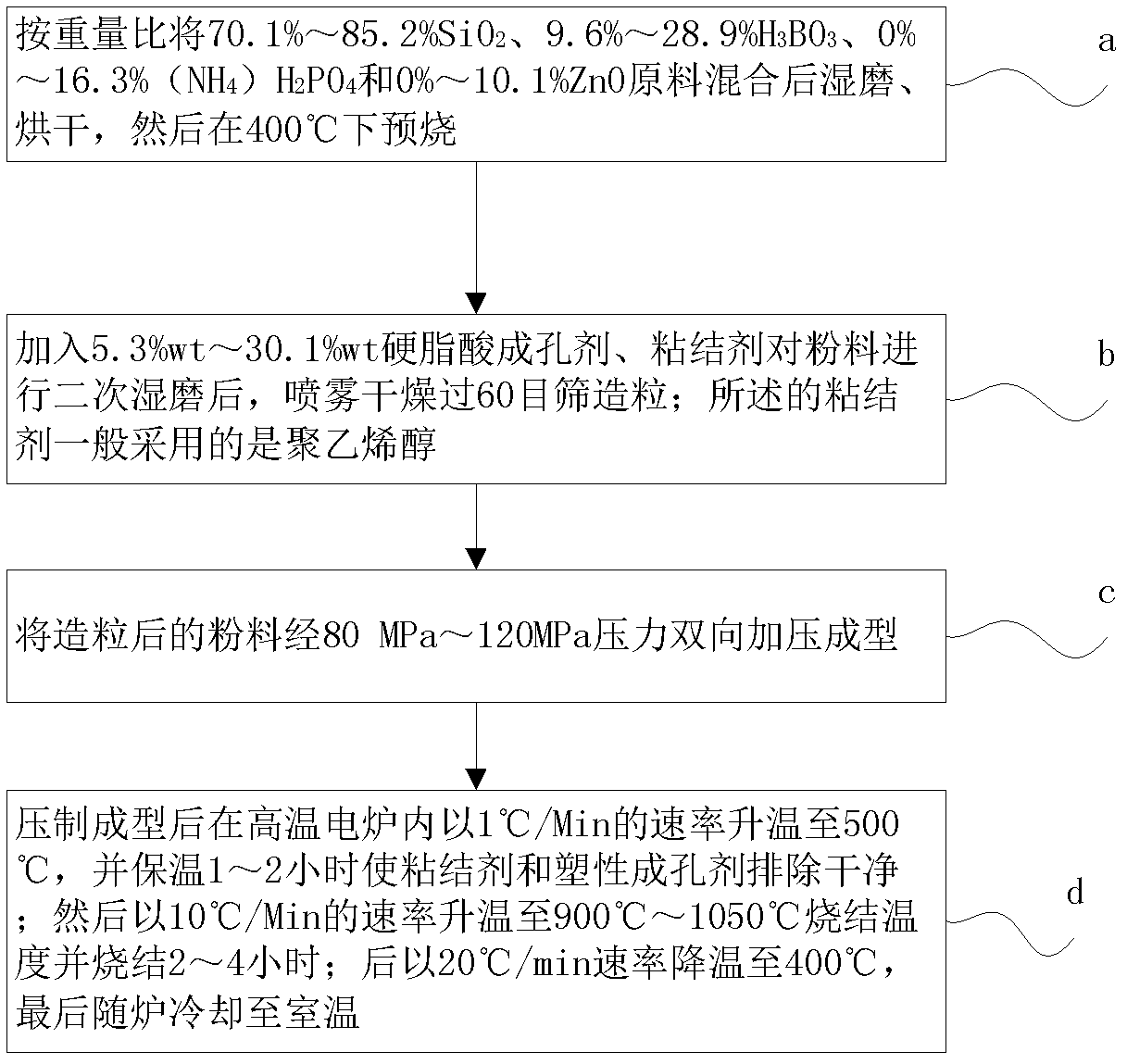

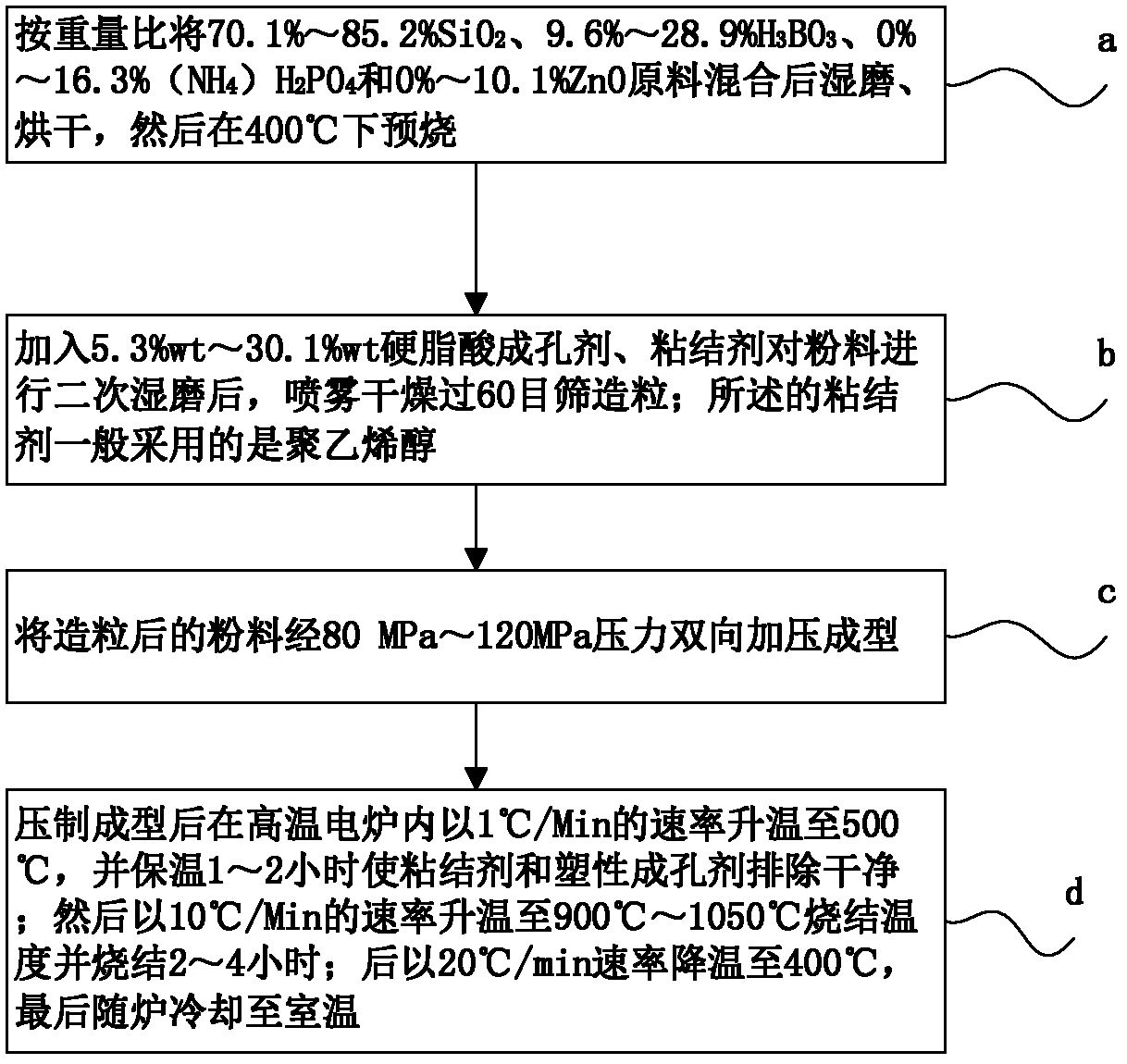

Method used

Image

Examples

Embodiment 1

[0038] 74.5% SiO by weight 2 , 13.6%H 3 BO 3 , 7.4% (NH 4 )H 2 PO 4 Mix with 4.5% ZnO raw material and add ethanol, use alumina balls as ball mills, mill in a planetary ball mill for 4 hours, then dry at 80°C for 12 hours, and pre-calcine the dried powder at 400°C for 2 hours;

[0039]Add the stearic acid pore-forming agent of 15.5%wt and the polyvinyl alcohol binder of 5.2%wt to the powder after calcining and carry out secondary ball milling, spray dry and cross 60 mesh sieves and granulate, the powder after granulation The material is formed by two-way pressure at 120MPa; after compression molding, the temperature is slowly raised to 500°C at a rate of 1°C / min in a high-temperature electric furnace, and kept for 2 hours to ensure that the polyvinyl alcohol binder and stearic acid pore-forming agent are completely removed. Then rapidly raise the temperature at 10°C / min to the highest firing temperature of 950°C, and keep it warm for 3 hours, then cool down to 400°C at a ...

Embodiment 2

[0042] 74.5% SiO by weight 2 , 13.6%H 3 BO 3 , 11.9% (NH 4 )H 2 PO 4 Mix with 0% ZnO raw materials and add ethanol, use alumina balls as ball mills, mill in a planetary ball mill for 4 hours, then dry at 80°C for 12 hours, and pre-calcine the dried powder at 400°C for 2 hours;

[0043] Add 10.5%wt stearic acid pore-forming agent and 5.2%wt polyvinyl alcohol binder to the powder after calcining, carry out secondary ball milling, spray dry and cross 60 mesh sieves for granulation, and the powder after granulation The material is formed by two-way pressure at 120MPa; after compression molding, the temperature is slowly raised to 500°C at a rate of 1°C / min in a high-temperature electric furnace, and kept for 2 hours to ensure that the polyvinyl alcohol binder and stearic acid pore-forming agent are completely removed. Then rapidly raise the temperature at 10°C / min to the highest firing temperature of 950°C, and keep it warm for 2 hours, then cool down to 400°C at a cooling ra...

Embodiment 3

[0046] 74.5% SiO by weight 2 , 13.6%H 3 BO 3 , 2.1% (NH 4 )H 2 PO 4 Mix with 9.8% ZnO raw material and add ethanol, use alumina balls as ball mills, mill in a planetary ball mill for 4 hours, then dry at 80°C for 12 hours, and pre-calcine the dried powder at 400°C for 2 hours;

[0047] Add the stearic acid pore-forming agent of 12.5%wt and the polyvinyl alcohol binder of 5.2%wt to the powder after calcining and carry out secondary ball milling, spray dry and cross 60 mesh sieves and granulate, the powder after granulation The material is formed by two-way pressure at 120MPa; after compression molding, the temperature is slowly raised to 500°C at a rate of 1°C / min in a high-temperature electric furnace, and kept for 2 hours to ensure that the polyvinyl alcohol binder and stearic acid pore-forming agent are completely removed. Afterwards, the temperature was rapidly raised to a maximum firing temperature of 950°C at 10°C / min, and kept at a temperature of 4 hours, then coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com