Method for detecting restricted substances in food contact material

A technology for food contact materials and food simulants, which is applied in the field of food analysis, can solve problems such as unfavorable food contact material safety supervision, no detection method is proposed, and achieve good economic and social benefits, high accuracy, and simple pretreatment effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

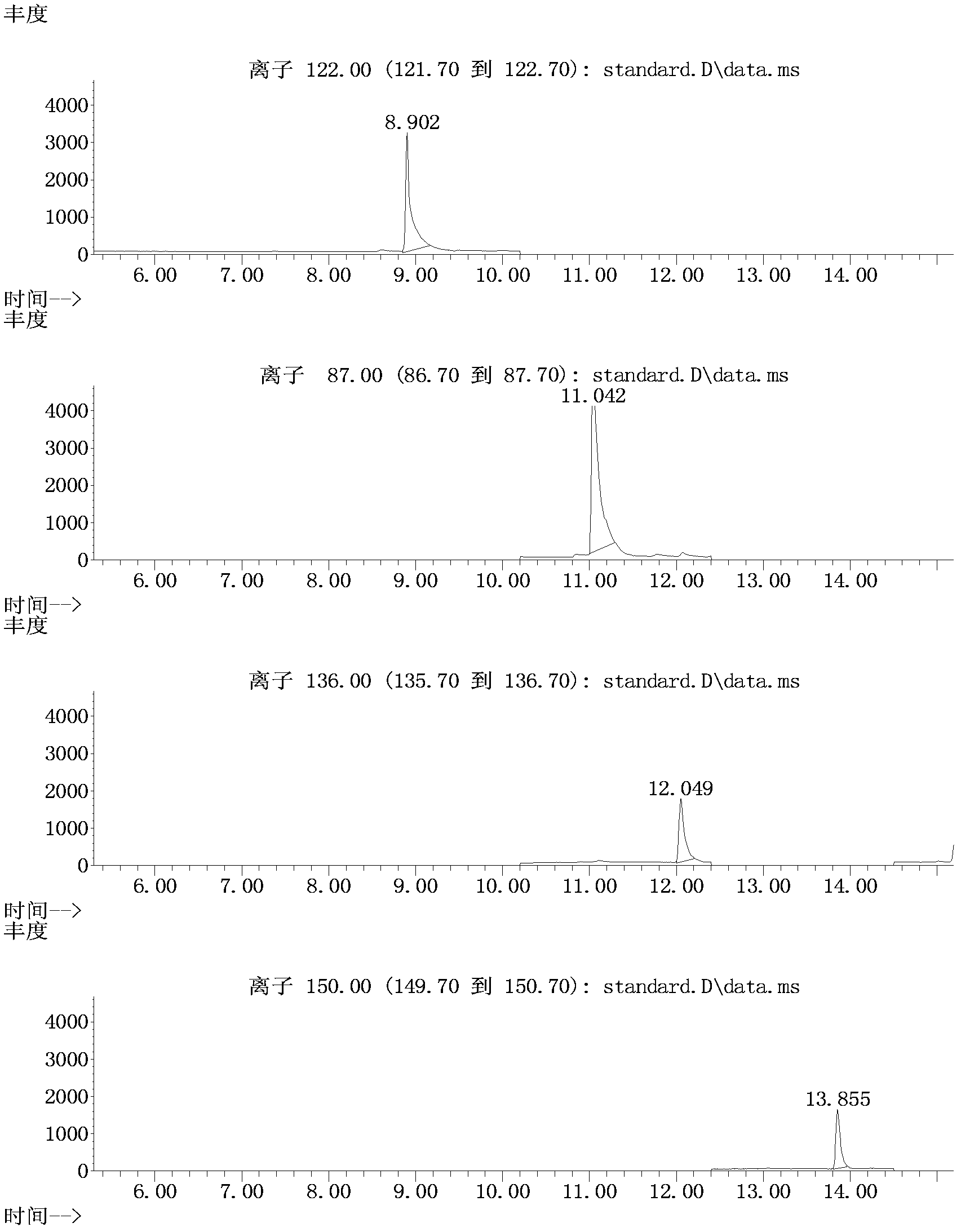

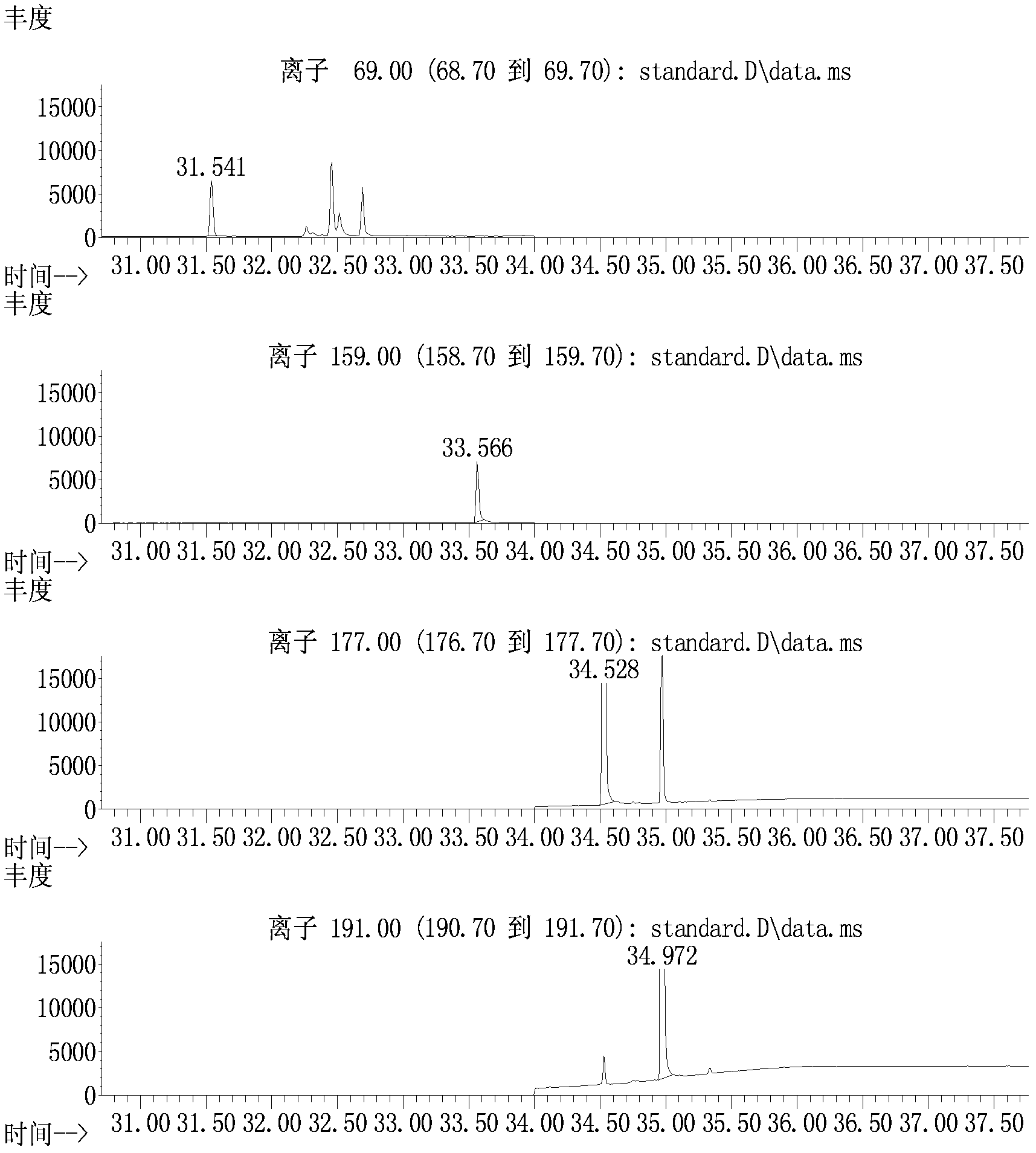

[0024] The present invention will be described in detail below in conjunction with specific embodiments. Determination of 11 kinds of restricted substances in 4 kinds of food simulants obtained in embodiment 1 tinplate three-piece can

[0025] Include the following steps:

[0026] (1) Preparation of standard solution

[0027] Weigh 2,6-di-tert-butyl-4-methylphenol, 2,2'-methylene-bis-(4-methyl-6-tert-butyl-phenol), 2,2'-methylene Each 500mg of methyl-bis-(4-ethyl-6-tert-butyl-phenol) was placed in a 25ml volumetric flask, and the volume was adjusted to the mark with methanol, and the concentration of the three compounds was prepared as a single-label reserve of 20mg / ml respectively. liquid.

[0028] Weigh 50 mg of the remaining eight compounds into 25 ml volumetric flasks, adjust the volume to the mark with methanol, and prepare single-label stock solutions with concentrations of each compound of 2 mg / ml.

[0029] Pipette a certain volume of single-standard stock solution ...

Embodiment 2

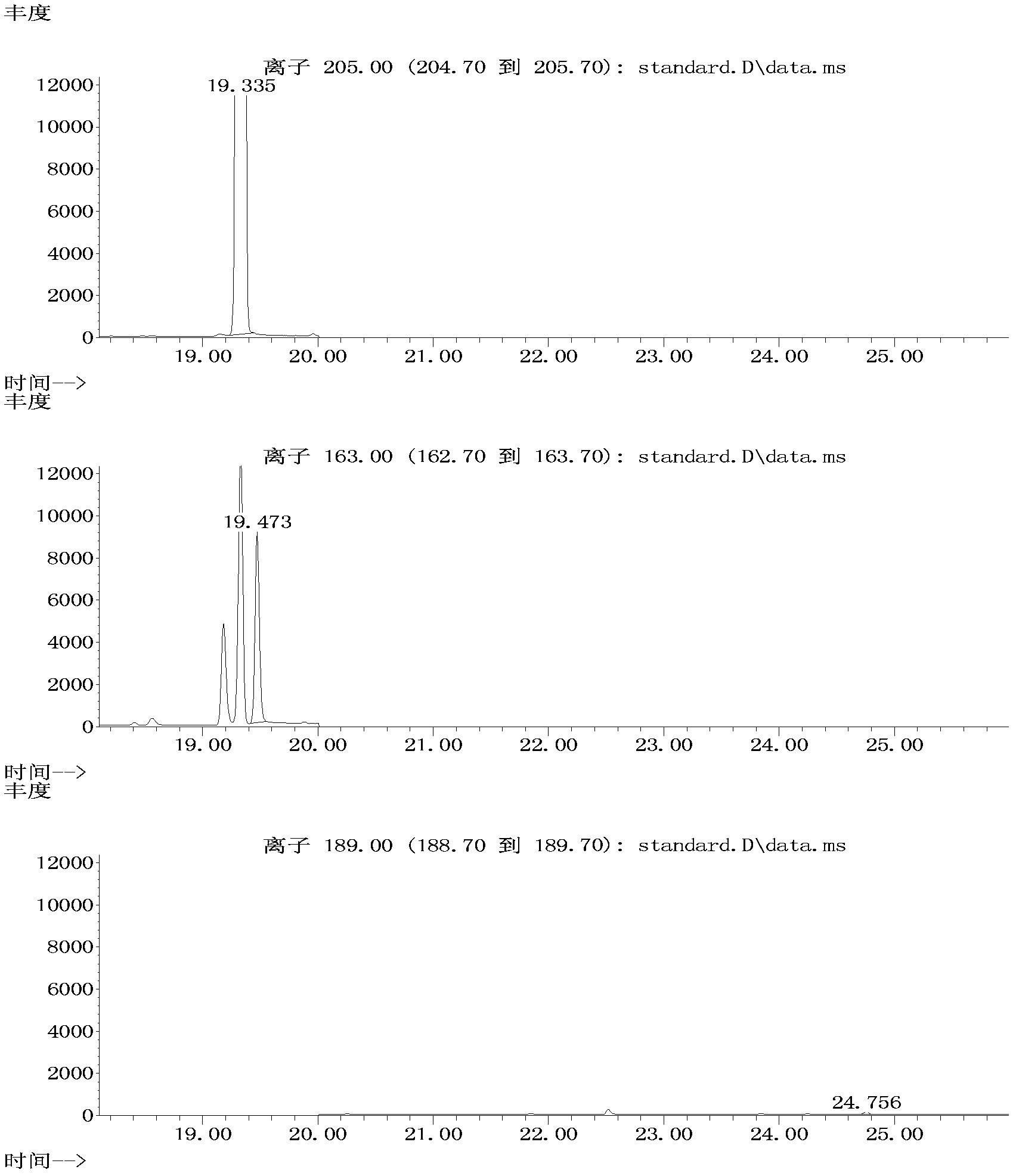

[0046] Embodiment 2 has added the determination of the food simulants of 11 kinds of restricted substance standard solutions

[0047] Include the following steps:

[0048] (1) Preparation of standard solution

[0049] With embodiment 1.

[0050] (2) Preparation of the test solution

[0051] Pipette 50 μl of the standard solution into 16 10ml colorimetric tubes, and use the four food simulants obtained in Example 1 to make up to the mark, and each food simulant to make up to 4 colorimetric tubes. Food simulants added with restricted substances were obtained, and the number of parallel samples was 4. Cover. Put the tinplate three-piece can in a constant temperature box, keep the temperature at 40°C for 240 hours, take out the tinplate three-piece can, pour the food simulant in it into a clean glass reagent bottle, and store the reagent bottle at 4°C.

[0052] Each food simulant is prepared into a test solution, and the preparation method is the same as in Example 1.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com