Magnetic valve type controllable electric reactor control system and control method

A control system and reactor technology, applied in the direction of variable inductance/transformer, transformer/inductor coil/winding/connection, circuit, etc., can solve the problems of partial discharge, slow control speed, overheating of iron fuel tank cover, etc. , to achieve the effect of preventing phenomenon and sampling aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

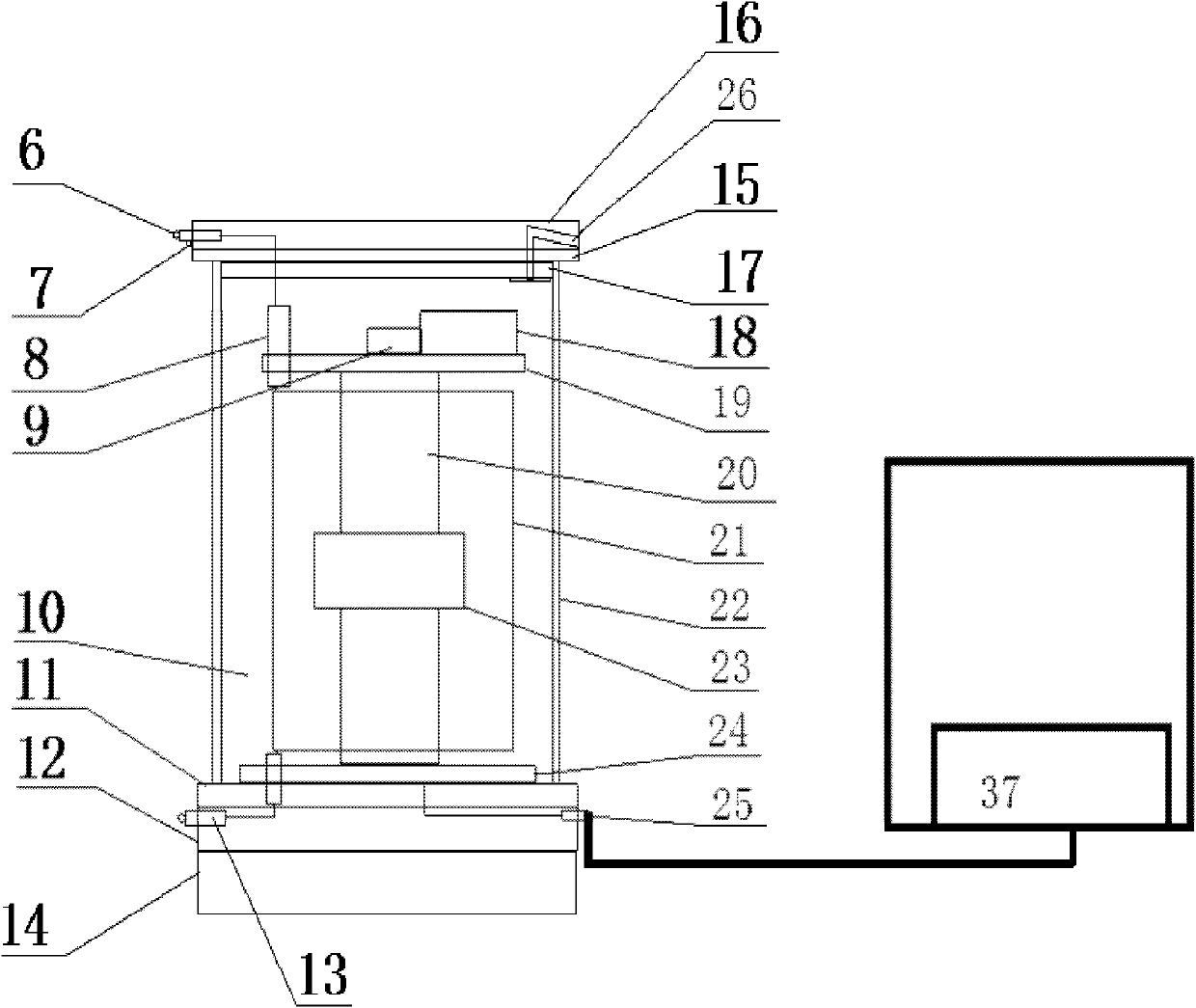

[0090] Figure 1A is a structural diagram of a single-phase MCR; Figure 1B is a schematic diagram of the principle of a single-phase MCR;

[0091] The magnetic valve type controllable reactor of the present invention has no side yoke structure, which constitutes a two iron core structure controllable reactor. The yoke constitutes a four-column iron core structure, and the iron core column I 4 and the iron core column II 5 are respectively provided with at least one small section section, and the upper and lower sides of the iron core column I 4 are symmetrically wound with coils A with the same number of turns 1. B. The upper and lower sides of the working iron core column II 5 are at least symmetrically wound with coils C and D with the same number of turns, and the number of turns of the coils A, B, C and D are all equal; the coils A, B, C, and D are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com