Reflective anode electrode for organic EL display

A reflective anode and display technology, applied in applications, instruments, circuits, etc., can solve the problem of high power consumption, and achieve the effects of low contact resistance, excellent luminous brightness characteristics, alkali corrosion resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

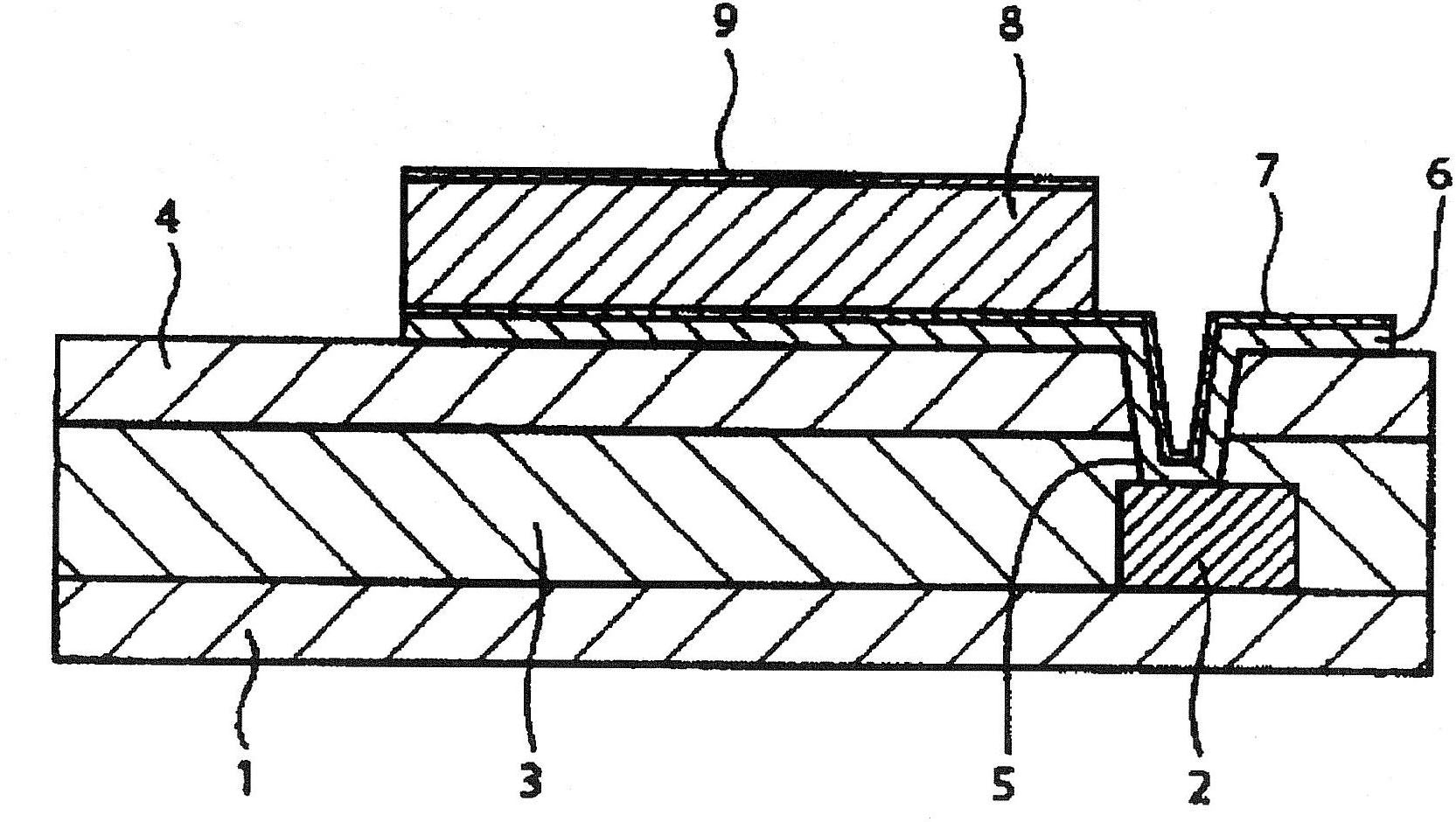

Image

Examples

Embodiment 1

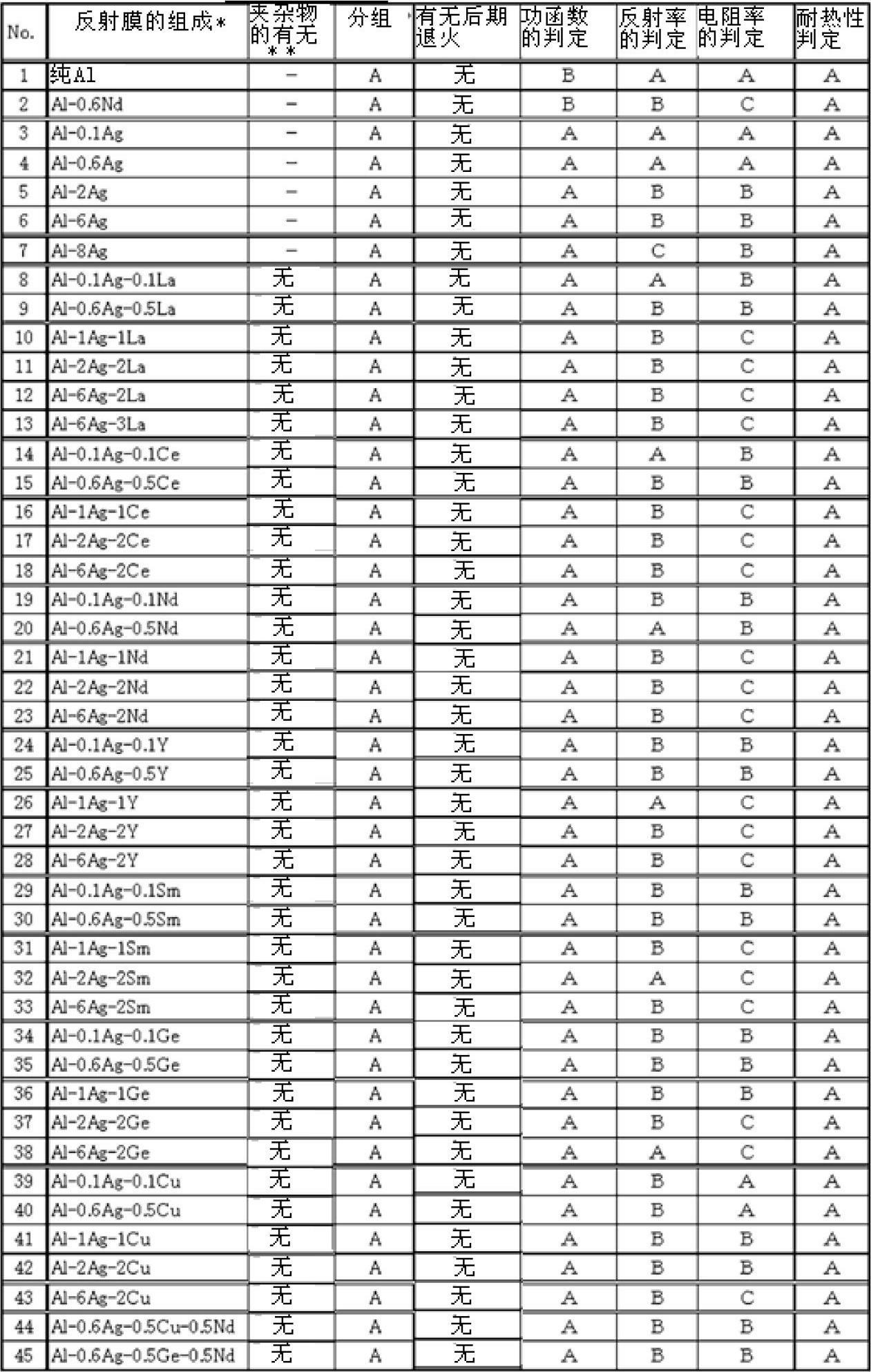

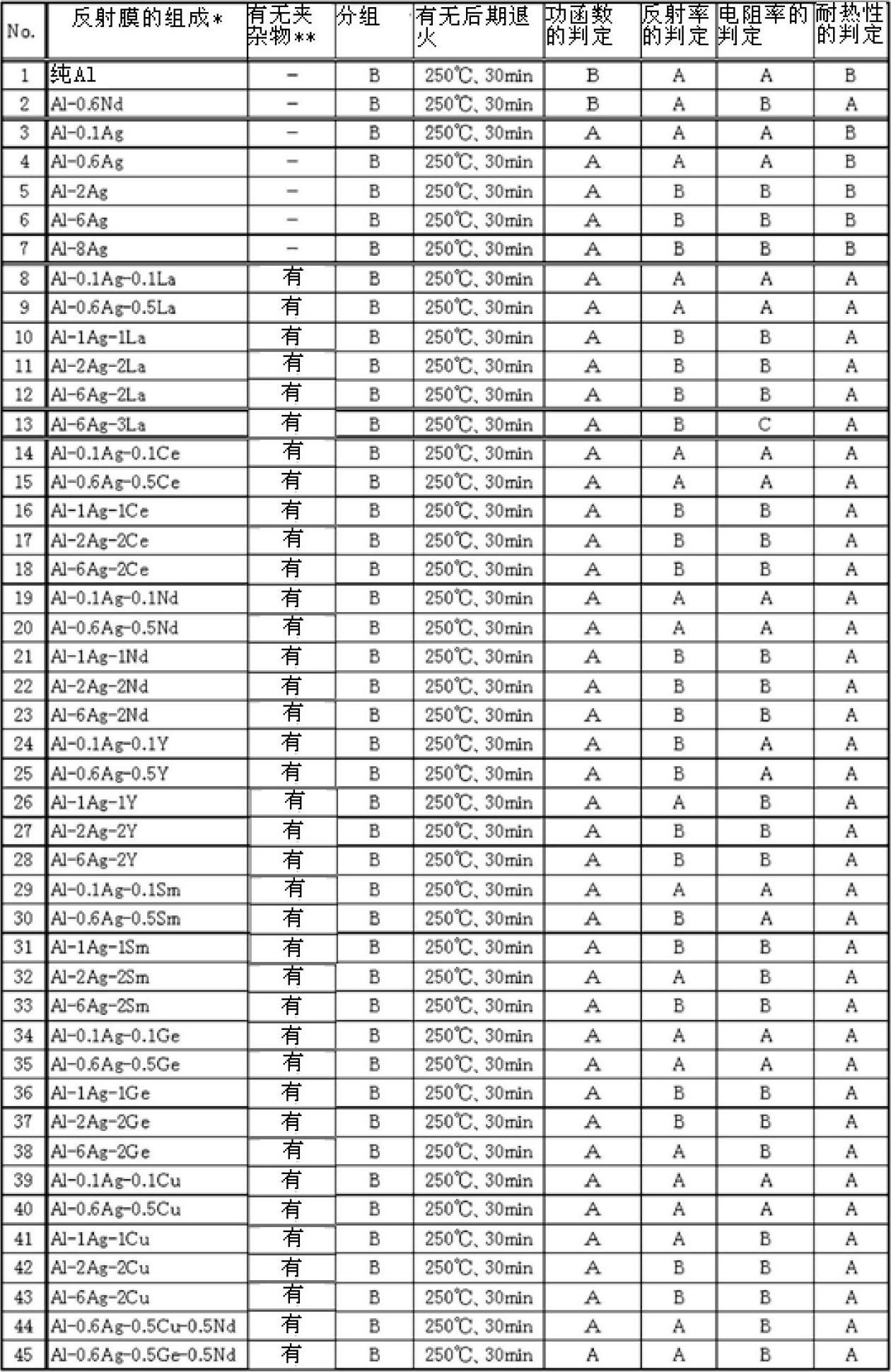

[0088] In this example, various Al alloy reflective films were used to study the effects on work function, reflectivity and resistivity without heat treatment (Group A, Table 1) or with post-annealing (Group B, Table 2) , In addition, the influence on heat resistance, which is a preferred characteristic, was also studied.

[0089] Specifically, first, an alkali-free glass plate (thickness: 0.7 mm) was used as a substrate, and a SiN film (thickness: 300 nm) was formed as a passivation film on the surface thereof using a plasma CVD apparatus. The film-forming conditions are: substrate temperature: 280°C, gas ratio: SiH 4 / NH 3 / N 2 =125 / 6 / 185, pressure: 137Pa, RF power: 100W. Further, on the surface, an Al alloy film (film thickness: about 100 nm) was formed as a reflective film by a sputtering method. The composition of the Al alloy film is shown in Table 1 and Table 2. In addition, the film formation conditions were substrate temperature: 25° C., pressure: 2 mTorr, and DC...

Embodiment 2

[0125] In this example, using an Al alloy reflective film with the same composition as in Example 1, it is studied when performing preliminary annealing and alkali solution treatment (group C, Table 3) or when performing preliminary annealing, alkali solution treatment and post-annealing (group D , Table 4), its effect on work function, reflectivity, resistivity and contact resistance, and also its effect on heat resistance and alkali corrosion resistance which are preferred characteristics.

[0126] First, each reflective film was formed in the same manner as in Example 1 described above. Next, the formed reflective films were classified into Group C and Group D. In Group C, after heat treatment (preliminary annealing) at 250° C. for 30 minutes in a nitrogen atmosphere, tetramethanone at a concentration of 0.4% by mass was used as an alkaline solution. Ammonium Hydroxide (TMAH) aqueous solution, alkaline solution treatment (TMAH treatment), immersion for 20 seconds, the same ...

Embodiment 3

[0148] In this example, the influence of the film thickness of the ITO film on the reflectance was investigated.

[0149] In detail, after forming each reflective film similarly to Example 1 mentioned above, it classified into A group and B group, and performed the same process as Example 1. In addition, the film thickness of the ITO film was changed to 5 to 50 nm by changing the film formation time of sputtering. In addition, for comparison, the same treatment was performed on pure Al and Al-0.6 atomic % Nd simulated in Patent Document 1.

[0150] Regarding the reflective anode electrode thus obtained, the reflectance was measured and evaluated in the same manner as in Example 1. These results are described in Table 5 and Table 6 together.

[0151] 【table 5】

[0152]

[0153] *: Unit of composition: atomic %, balance: Al and unavoidable impurities

[0154] 【Table 6】

[0155]

[0156] *: Unit of composition: atomic %, balance: Al and unavoidable impurities

[0157]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com