Olefin disproportionation catalyst and preparation method thereof

A technology of olefin disproportionation and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of fast deactivation and low catalyst activity, and achieve carbon The effect of reducing accumulation, solving low catalyst activity, and good macropore penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Synthesis of Polystyrene (PS) Microsphere Particle Templates

[0048] Take 875ml of water, 0.884g of emulsifier sodium styrene sulfonate and 0.567g of stabilizer sodium bicarbonate into the reactor, stir and raise the temperature to 75°C, then add 125ml of styrene, continue stirring for 1h, add 0.567g of initiator over two Potassium sulfate, stirring at 75°C for 18 hours to obtain a monodisperse polystyrene emulsion. The particle size of the polystyrene microspheres measured by a Zetasizer Nano-ZS dynamic light scattering particle size analyzer of Malvern Instrument Co., Ltd. is 139 nm, and the relative standard deviation of the particle size is 3.2%.

Embodiment 2

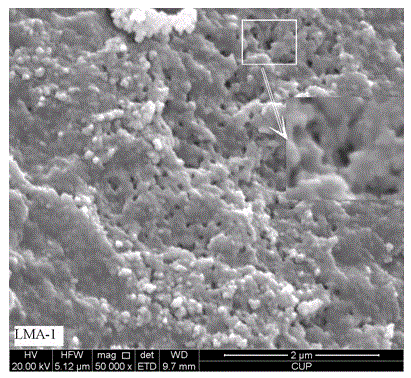

[0050] One of preparation of mesoporous / macroporous alumina support

[0051] Disperse 40.8 g of SB powder in 1L of deionized water, stir and drop 1 mol / L nitric acid solution (until the pH of the suspension = 3.0~4.0) at 80°C for degelation, and obtain about 1 mol / L alumina Sol. Dissolve 34.8g of P123 in alumina sol, continue stirring for 1 hour, add PS microsphere suspension (the mass ratio of PS microspheres to alumina is 10%), mix well, and age the obtained material solution at room temperature , washed, filtered, dried, and then raised to 300°C at a rate of 1°C / min in a muffle furnace, then roasted at a constant temperature for 3 h, and then raised to 550°C at a rate of 1°C / min, and roasted at a constant temperature for 5 h , to obtain mesoporous / macroporous alumina support LMA-1. The BET specific surface area measured by nitrogen adsorption method is 230m 2 / g, the mesopore diameter is 13.4nm, and the pore volume measured by water titration is 1.22cm 3 / g, the spheric...

Embodiment 3

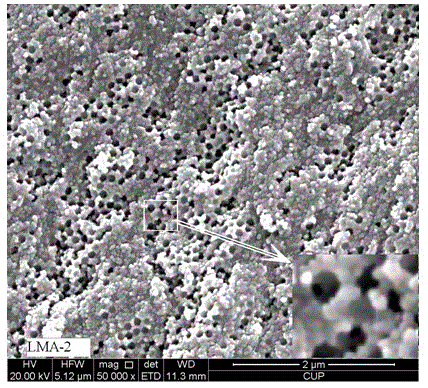

[0053] Preparation of Mesoporous / Macroporous Alumina Support Part 2

[0054] Disperse 40.8 g of SB powder in 1L of deionized water, stir and drop 1 mol / L nitric acid solution (until the pH of the suspension = 3.0~4.0) at 80°C for degelation, and obtain about 1 mol / L alumina Sol. Dissolve 34.8g of P123 in alumina sol, continue stirring for 1 hour, add PS microsphere suspension (the mass ratio of PS microspheres to alumina is 20%), mix well, and age the obtained material solution at room temperature , washed, filtered, dried, and then raised to 300°C at a rate of 1°C / min in a muffle furnace, then roasted at a constant temperature for 3 h, and then raised to 550°C at a rate of 1°C / min, and roasted at a constant temperature for 5 h , to obtain mesoporous / macroporous structure alumina carrier LMA-2. The BET specific surface area measured by nitrogen adsorption method is 259m 2 / g, the mesopore diameter is 11.7nm, and the pore volume measured by water titration is 1.61cm 3 / g, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com