Synthetic method for high length-diameter ratio layered doubled hydroxides grafted by organosilane

A synthesis method and organosilane technology, which is applied in the synthesis field of high aspect ratio organosilane grafted hydrotalcite mineral materials, can solve the problems of large stacking thickness, single shape, poor affinity, etc., and achieve uniform grain size distribution, Uniform shape and particle size to prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

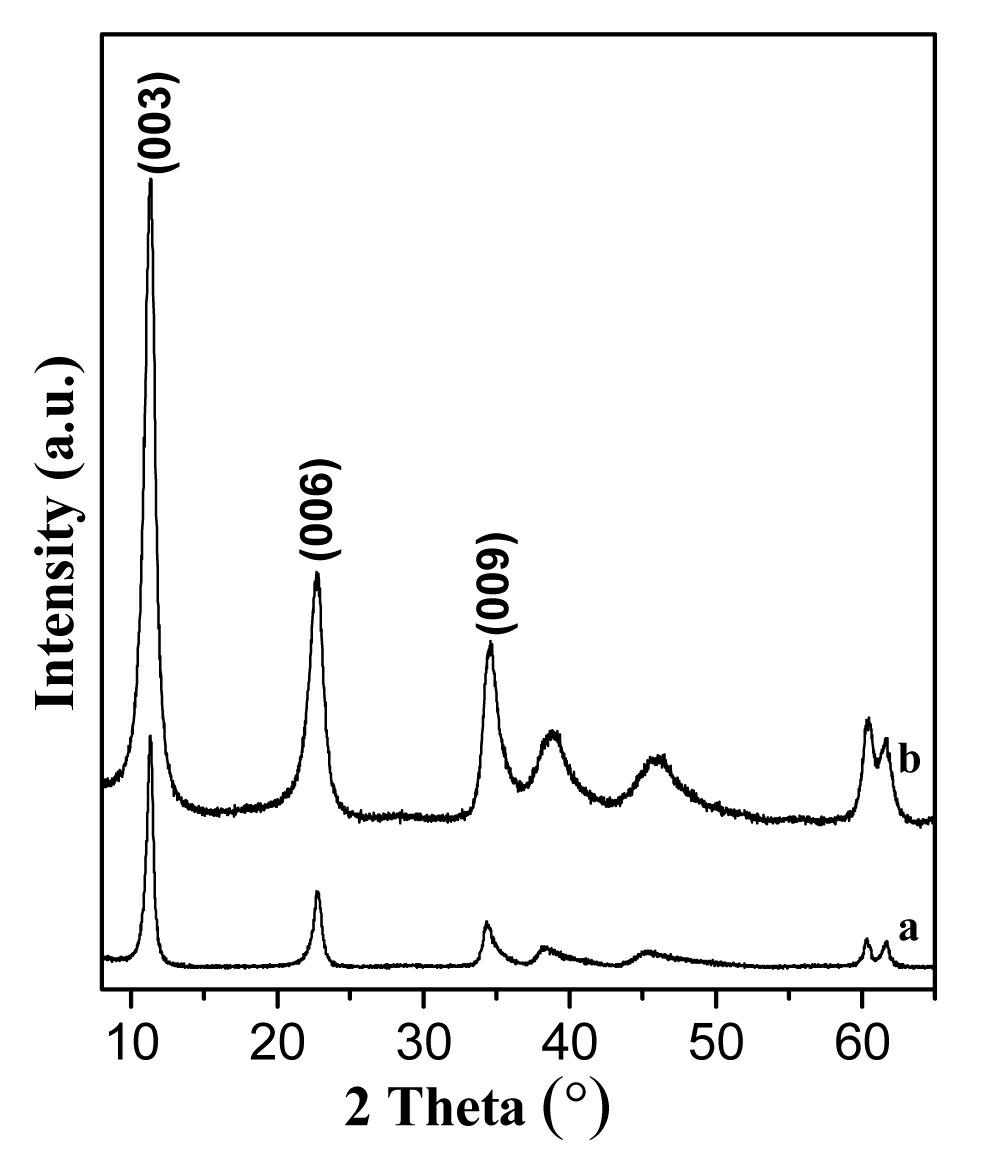

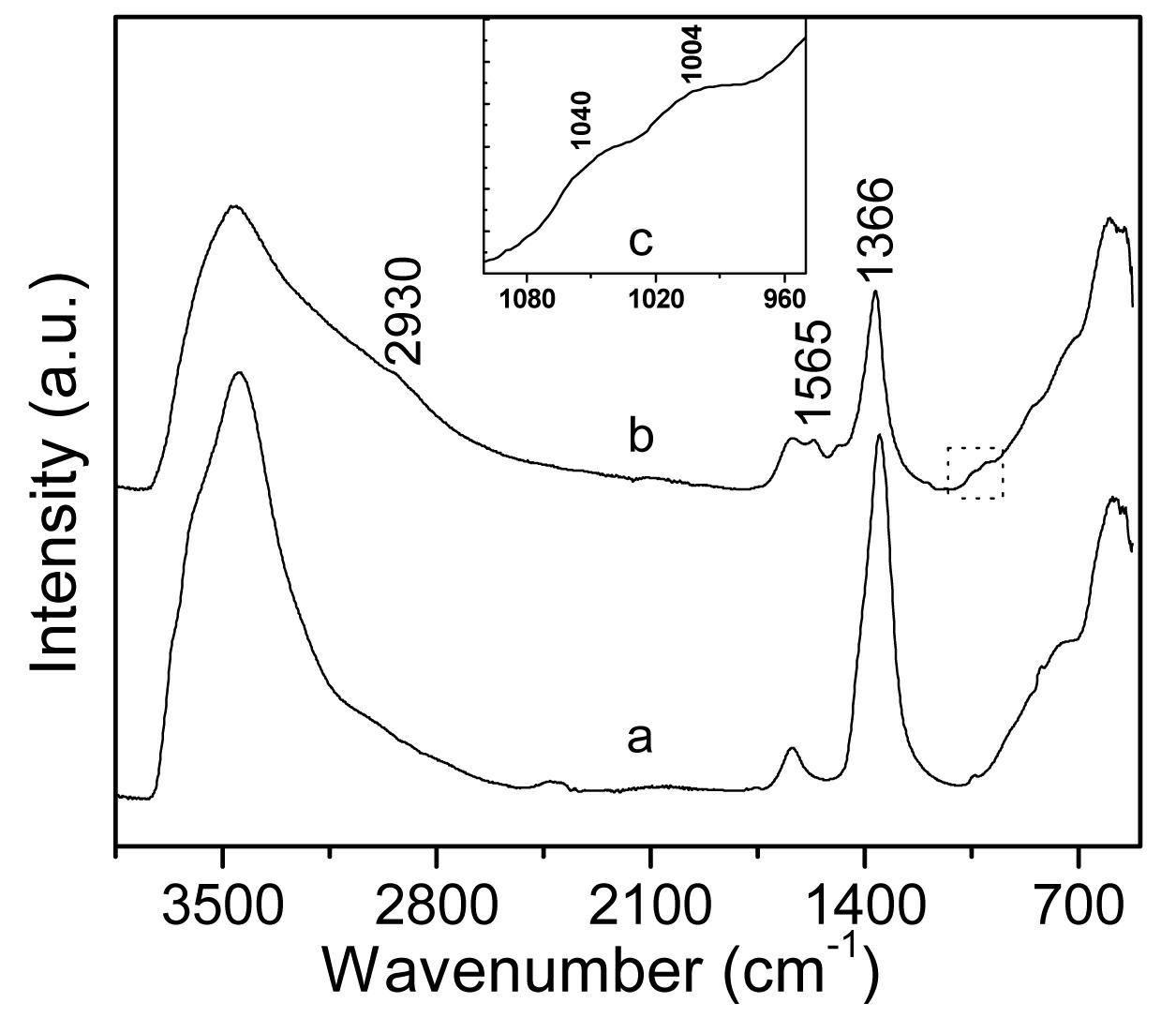

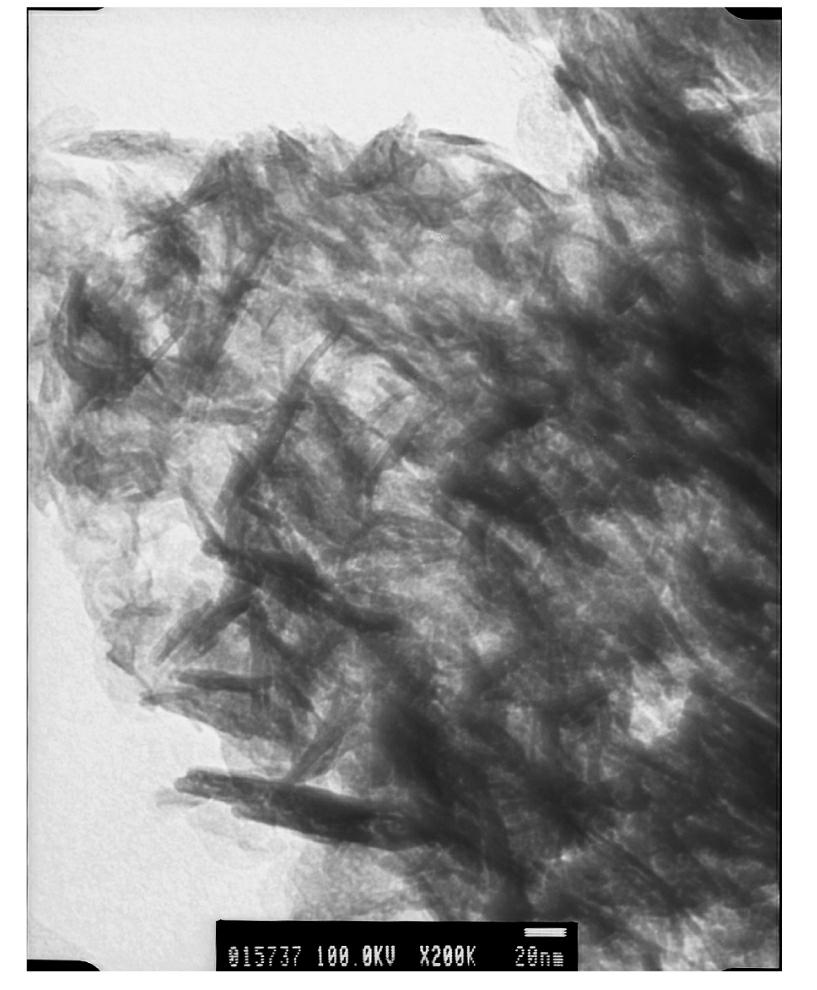

[0033] in Mg 2+ 、Al 3+ Hydrotalcite is a metal framework ion, gamma -Acicular organosilane-grafted hydrotalcite nanocrystals prepared with aminopropyltriethoxysilane as a shape-controlling and grafting modifier.

[0034] Weigh 9.6 g Mg(NO 3 ) 2 ?6H 2 O and 4.7 g Al(NO 3 ) 3 ?9H 2 O is co-dissolved in 44 cm 3 In deionized water (solution A), 4 g NaOH was dissolved in 50 cm 3 deionized water (solution B). At room temperature, solutions A and B were added dropwise to 50 ml of deionized water, and stirred rapidly, and the dropping speed was controlled to stabilize the pH value of the mixed solution at about 10. After the dropwise addition, it was washed and centrifuged until the centrifuged liquid became neutral, and the obtained precipitate was dried at 80°C for 12 h to obtain a hydrotalcite with a Mg / Al ratio of 3. The finely ground solid powder was calcined at 500°C for 6 h to obtain white composite metal oxide powder. Weigh 1.0 g composite metal oxide powder and a...

Embodiment 2

[0037]in Mg 2+ 、Al 3+ Hydrotalcite is used as metal skeleton ion, and γ-aminopropyltrimethoxysilane is used as morphology control and grafting modifier to prepare rod-shaped organosilane-grafted hydrotalcite nanocrystals.

[0038] Weigh 19.2 g Mg(NO 3 ) 2 ?6H 2 O and 9.4 g Al(NO 3 ) 3 ?9H 2 O is co-dissolved in 88 cm 3 In deionized water (solution A), 8 g NaOH was dissolved in 100 cm 3 deionized water (solution B). At room temperature, solutions A and B were added dropwise to 100 ml of deionized water, and stirred rapidly, and the dropping speed was controlled to stabilize the pH value of the mixed solution at about 10. After the dropwise addition, wash and centrifuge until the centrate is neutral. The resulting precipitate was dried at 80 °C for 12 h to obtain a hydrotalcite with a Mg / Al ratio of 3. The finely ground solid powder was calcined at 500°C for 6 h to obtain white composite metal oxide powder. Weigh 2.0 g composite metal oxide powder and add to 100 ml, ...

Embodiment 3

[0040] With Zn 2+ 、Al 3+ Hydrotalcite is a metal framework ion, gamma -Aminopropyltrimethoxysilane as a Morphology Controlling and Grafting Modifier for the Preparation of Fibrous Hydrotalcite Nanocrystals.

[0041] Weigh 10.9 g Zn(NO 3 ) 2 ?6H 2 O and 4.7 g Al(NO 3 ) 3 ?9H 2 O is co-dissolved in 44 cm 3 In deionized water (solution A), 8 g NaOH was dissolved in 50 cm 3 deionized water (solution B). Add solutions A and B dropwise to 50 ml deionized water at room temperature, and stir rapidly, and control the rate of addition to stabilize the pH value of the mixed solution at about 9. After the dropwise addition, wash and centrifuge until the centrate is neutral. The resulting precipitate was dried at 80 °C for 12 h to obtain a hydrotalcite with a Zn / Al ratio of 3. The finely ground solid powder was calcined at 500°C for 6 h to obtain white composite metal oxide powder. Weigh 2.0g composite metal oxide powder and add to 100ml, 0.3mol L -1 Na 2 CO 3 solution, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com