Cubic or sheet-shaped nano SAPO-34 molecular sieve and application thereof

A SAPO-34, molecular sieve technology, applied in the field of molecular sieves, can solve the problems of insufficient uniformity of molecular sieve crystal size and morphology, long processing and synthesis time, low molecular sieve yield, etc., and achieves short processing and synthesis time, low cost, and molecular sieve yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

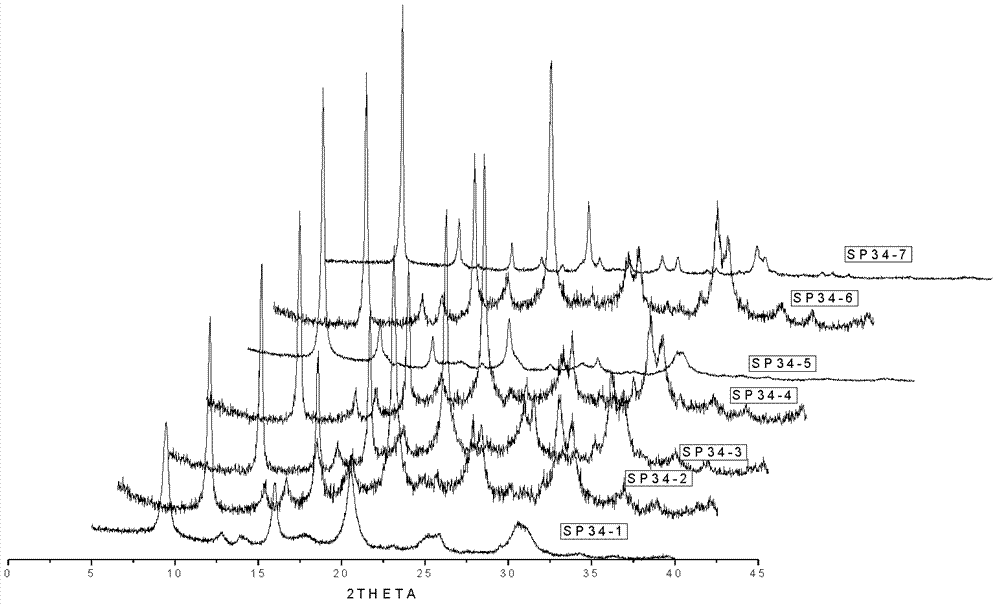

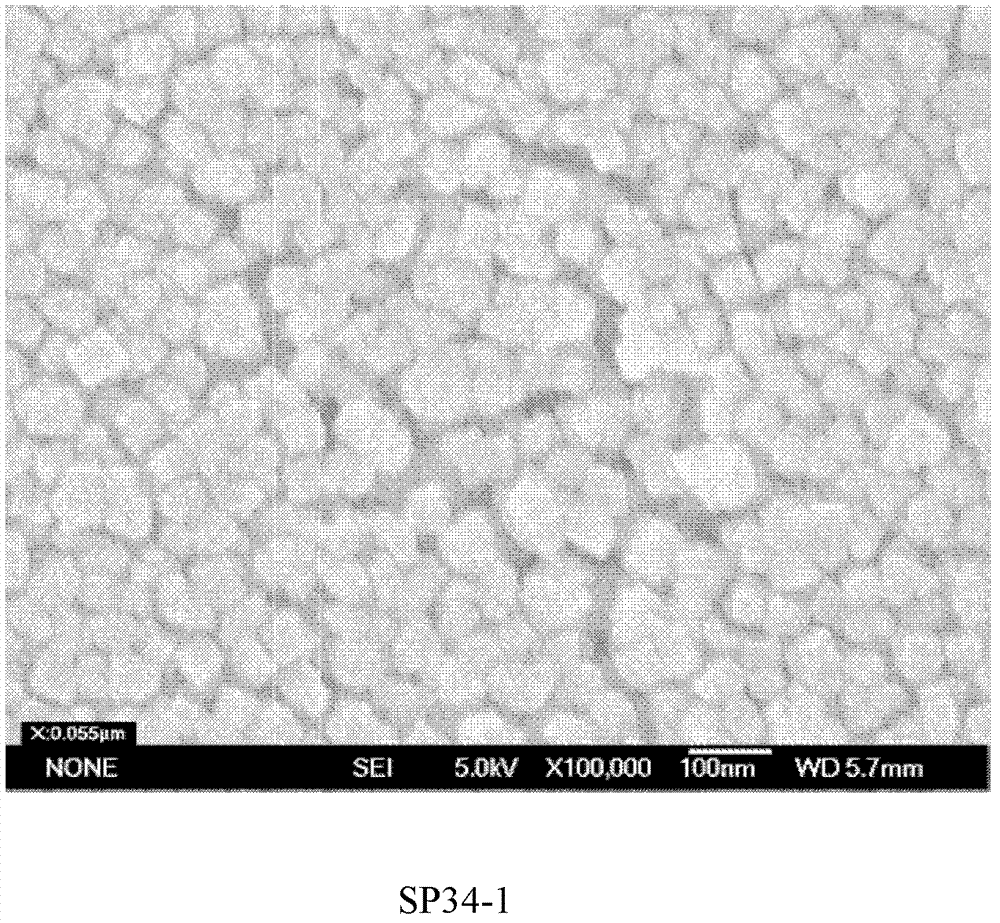

[0046] Mix and stir tetraethyl orthosilicate, aluminum isopropoxide, water, tetraethylammonium hydroxide and treat at 20°C under autogenous pressure for 36 hours to obtain a mixture; add phosphoric acid and in situ to the above mixture, and Stirring treatment under autogenous pressure for 12 hours to obtain the initial gel mixture of SAPO-34 molecular sieve; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is TEAOH: 0.7SiO 2 :P 2 o 5 : Al 2 o 3 :30H 2 O: 20S (S is water); put the initial gel mixture into a microwave reactor, heat it to 180° C. under a power of 200 watts in a closed manner, and carry out constant temperature crystallization under autogenous pressure for 1 hour. Then, the solid product is centrifuged, washed with deionized water, and dried in the air at room temperature to obtain the original powder of SAPO-34 molecular sieve. SAPO-34 molecular sieve (Code SP34-1) with a medi...

Embodiment 2

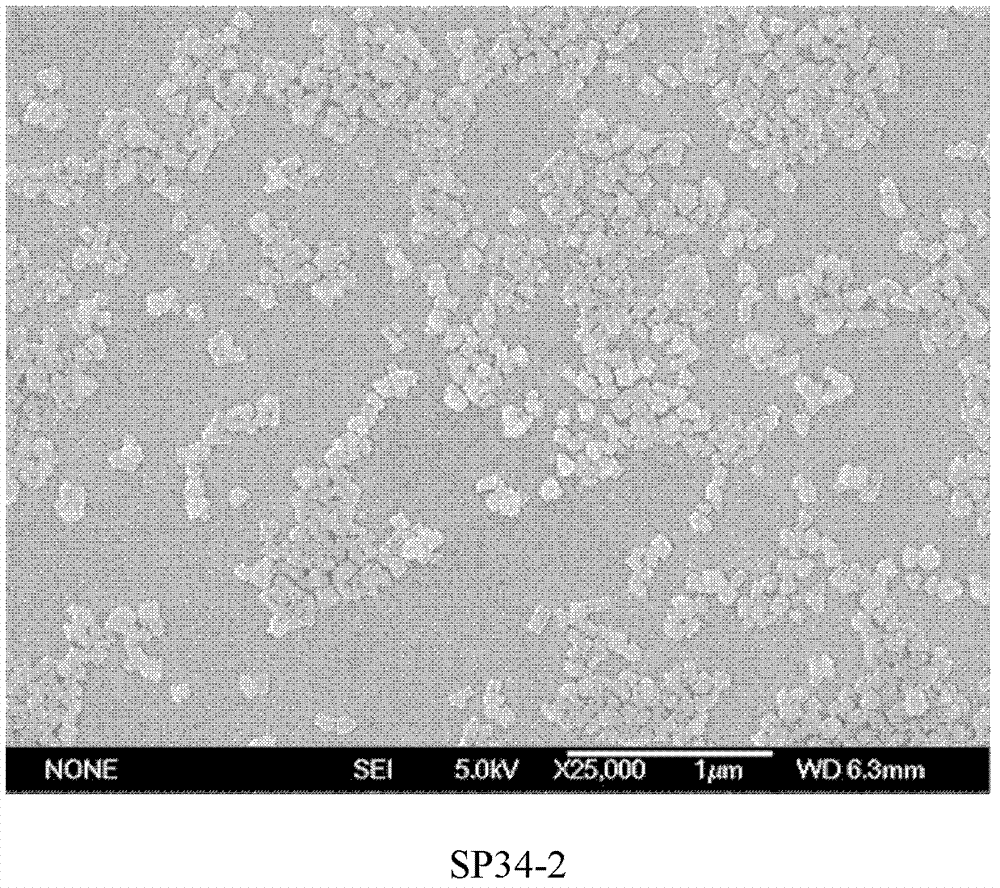

[0050] Active silica, boehmite, water, and tetraethylammonium hydroxide were mixed and stirred at 60°C for 10 hours under autogenous pressure to obtain a mixture; phosphoric acid and water were added to the above mixture in situ, and autogenous Stir under pressure for 0.5 hours to obtain SAPO-34 molecular sieve; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 1.2TEAOH: 0.7SiO 2 : 1.1P 2 o 5 : Al 2 o 3 :30H 2 O: 10S (S is water); put the obtained initial gel mixture into a microwave reactor, heat it to 160° C. under a power of 200 watts in a closed manner, and carry out constant temperature crystallization under autogenous pressure for 4 hours. Then, the solid product is centrifuged, washed neutral with deionized water, and dried in the air to obtain the original powder of SAPO-34 molecular sieve. SAPO-34 flake molecular sieve (No. SP34-3). The XRD spectrum of the original powder sample...

Embodiment 3

[0054] Silica sol, aluminum isopropoxide, water, tetraethylammonium hydroxide were mixed and stirred, and treated at 60°C under autogenous pressure for 4 hours to obtain a mixture; phosphoric acid and triethylene glycol were added to the above mixture in situ , stirred for 5 hours under autogenous pressure to obtain SAPO-34 molecular sieve; the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is TEAOH: 0.5SiO 2 :P 2 o 5 : Al 2 o 3 :30H 2 O: 10S (S is triethylene glycol); put the obtained initial gel mixture into a microwave reactor, heat it up to 230°C in a closed manner under 800 watts of power, and carry out constant temperature crystallization under autogenous pressure for 0.5 hours . Then, the solid product is centrifuged, washed with deionized water, and dried in the air to obtain the original powder of SAPO-34 molecular sieve. After the original powder is roasted at 550 ° C for 6 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com