Titanium plant tail gas treatment method as well as barium chloride produced by using titanium plant tail gas treatment method and production method of barium chloride

A barium chloride and tail gas technology, applied in separation methods, chemical instruments and methods, calcium/strontium/barium chloride, etc., can solve the problems of large energy consumption of evaporation, and achieve the purpose of reducing energy consumption, reducing evaporation, and increasing driving force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

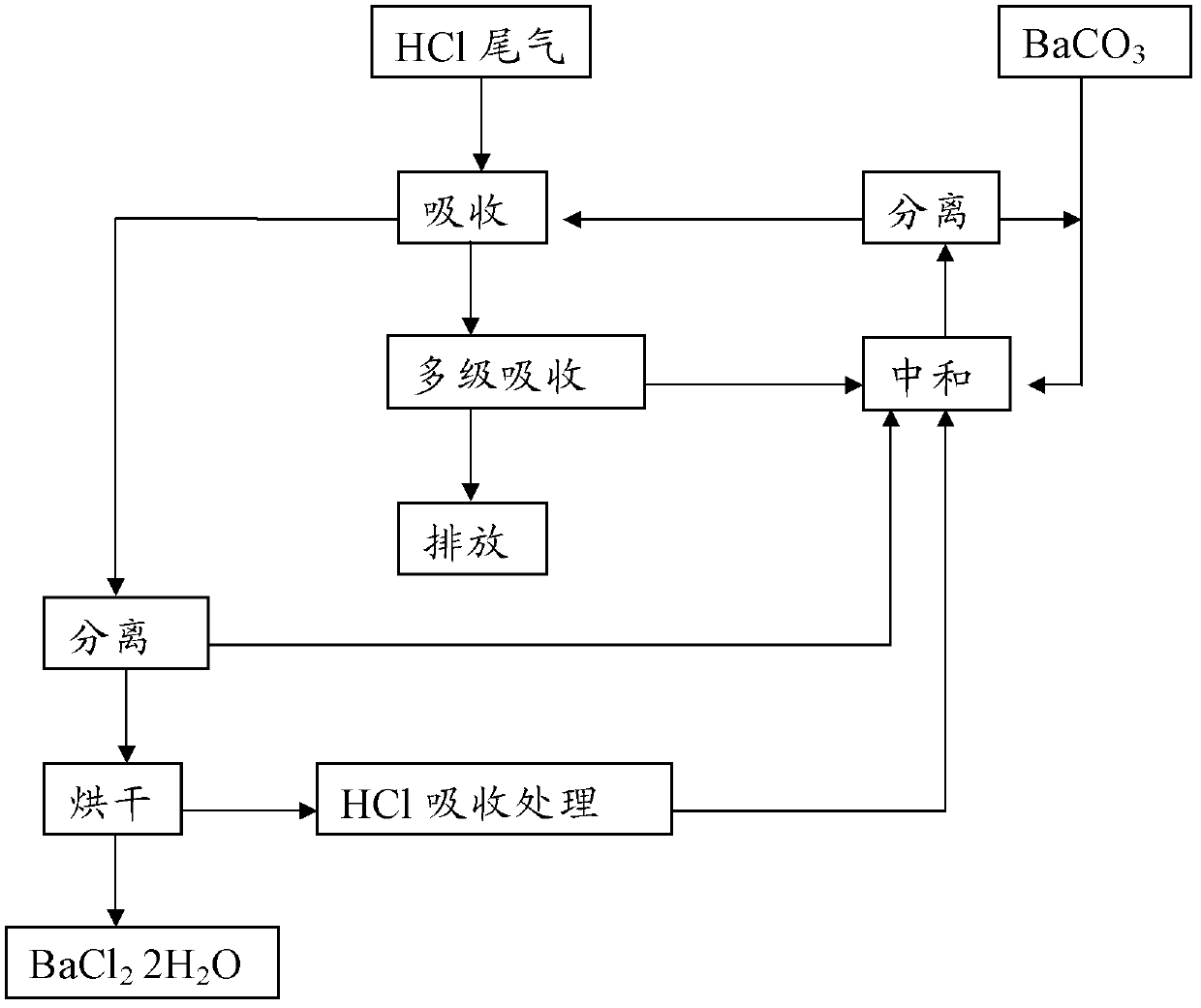

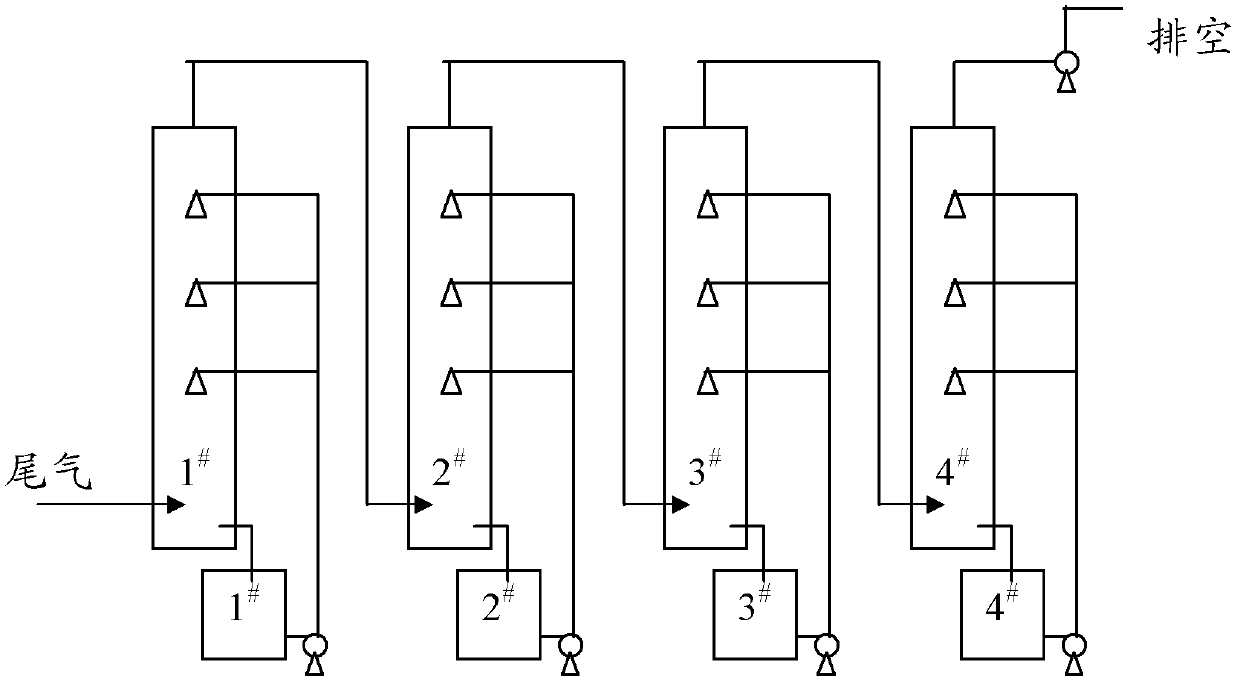

[0069] refer to figure 2 Shown, utilize the method for preparing barium chloride from titanium factory tail gas, comprise the steps:

[0070] (1) to 1 # ,2 # 、3 # Add the industrial barium carbonate of 150kg respectively in the circulation slurry tank, add water after adding and be mixed with the barium carbonate / water slurry that mass content is 20%; To 4 # Add 150kg of industrial-grade barium hydroxide octahydrate to the circulating slurry tank, and then add water to prepare a 0.5mol / L barium hydroxide solution; according to 12L / m 3 The liquid-gas ratio is used to set the circulating liquid spray volume of all circulating pumps, turn on the circulating pump, and let the tail gas into the absorption reaction, and the flow rate of the tail gas is 7000m 3 / h.

[0071] (2) With the continuous progress of tail gas absorption reaction, 1 # The acidity in the circulating slurry tank increases, when 1 # In the circulating slurry tank [H + ]=2.0mol / L, move all the mixed slur...

Embodiment 2

[0075] (1) to 1 # ,2 # 、3 # Add the industrial barium carbonate of 200kg respectively in the circulation slurry tank, add water after adding and be mixed with the barium carbonate / water slurry that mass content is 25%; To 4 # Add 200kg of industrial-grade barium hydroxide octahydrate to the circulating slurry tank, and then add water to prepare a 1.0mol / L barium hydroxide solution; according to 8L / m 3 The ratio of liquid to gas is used to set the spray volume of the circulating liquid of the circulating pump, turn on the circulating pump, and feed the exhaust gas to carry out the absorption reaction. The flow rate of the exhaust gas is 8000m 3 / h.

[0076] (2) With the continuous progress of tail gas absorption reaction, 1 # The acidity in the circulating slurry tank increases, when 1 # In the circulating slurry tank [H + ]=2.4mol / L, all the mixed slurry in the circulating slurry tank is moved to a conventional filter device for filtration and separation to obtain solid ...

Embodiment 3

[0080] (1) to 1 # ,2 # 、3 # Add the industrial barium carbonate of 200kg respectively in the circulation slurry tank, add water after adding and be mixed with the barium carbonate / water slurry that mass content is 23%; To 4 # Add 200kg of industrial-grade barium hydroxide octahydrate to the circulating slurry tank, and then add water to prepare a 0.8mol / L barium hydroxide solution; according to 10L / m 3 The ratio of liquid to gas is used to set the spray volume of the circulating liquid of the circulating pump, turn on the circulating pump, and feed the exhaust gas to carry out the absorption reaction. The flow rate of the exhaust gas is 9000m 3 / h.

[0081] (2) With the continuous progress of tail gas absorption reaction, 1 # The acidity in the circulating slurry tank increases, when 1 # In the circulating slurry tank [H + ]=3.11mol / L, all the mixed slurry in the circulating slurry tank is moved to a conventional solid-liquid separation device (such as a filter device) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com