Preparation method and use of 3,3'-methylenebis(1H-Indole)

A technology based on bisindole and indole, which is applied in the directions of medical preparations containing active ingredients, pharmaceutical formulations, organic active ingredients, etc. The effect of cheap and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The room temperature synthesis of the methylenyl bisindole that embodiment 1 p-toluenesulfonic acid and a certain proportion of water and technical ethanol participate in

[0101] The synthetic reaction equation is as follows:

[0102]

[0103] The synthesis process is as follows:

[0104] After adding 29.5 grams of indole and 0.45 grams of p-toluenesulfonic acid into the four-necked flask, add 150 mL of industrial alcohol with a mass fraction of 95% and 100 mL of water to completely dissolve the reaction substrate indole, and drop it under nitrogen protection and mechanical stirring. Add 10 mL of 40% formaldehyde aqueous solution, and react at room temperature (25-30° C.) for 24 hours after the dropwise addition, and a solid product will be precipitated during the reaction.

[0105] Identification of the product:

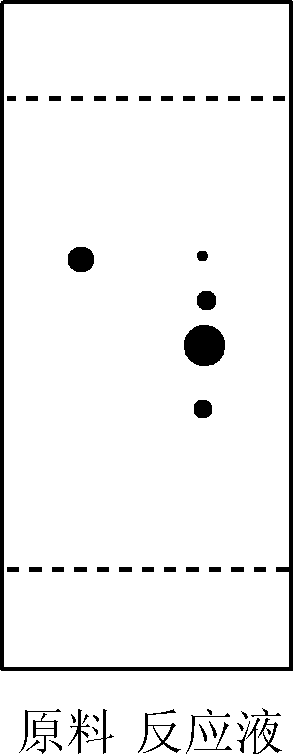

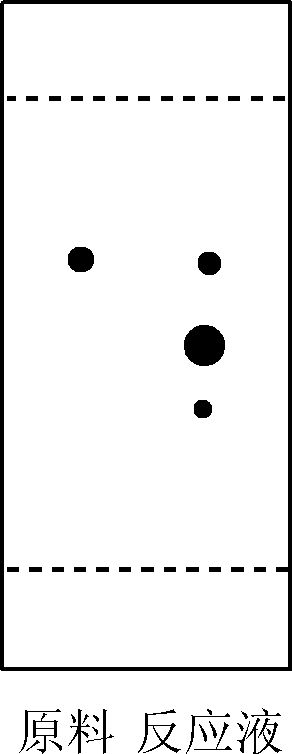

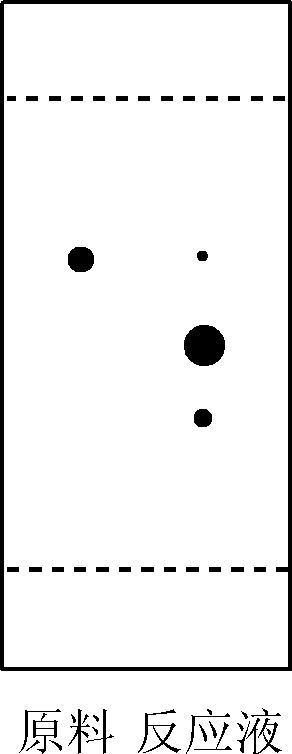

[0106] The remaining reaction solution and sampled raw material solution in the above reaction process were taken for thin-layer chromatography (TLC) m...

Embodiment 2

[0108] The purification of embodiment 2 methylene bisindole

[0109] The reaction system carried out in Example 1 was filtered to separate the solid product, which was the crude product; the separated reaction liquid was distilled under reduced pressure to recover the ethanol therein.

[0110] Experiments have found that the solid product is directly recrystallized, and the water in it will greatly affect the yield and purity of recrystallization purification, so rinsing is required. Take 31.7 g of the wet solid product isolated in Example 1 (that is, it does not need to be dried and does not affect the crystallization efficiency), and the crude product is rinsed with 120 mL of methanol under vacuum filtration.

[0111] The washed solid product was mixed with 60 mL of ethyl acetate, heated to 70-78°C with stirring to dissolve, then naturally cooled to room temperature, and the solid was precipitated by filtration. Then, add 50 mL of ethyl acetate to the solid, heat to 70-78 °...

Embodiment 3

[0112] The drug application test of embodiment 3 methylenyl bisindole

[0113] All cell lines used in this assay can be purchased from the American Type Culture Collection (ATCC).

[0114] 1. In vitro killing experiment of Colon38 cells

[0115] Source: Colon38 cells are mouse colon cancer cells, which are adherent cells.

[0116] Medium: 164090% (culture solution) + NCS (newborn calf serum) 10% + 1ml penicillin streptomycin mixed solution

[0117] Culture conditions: in 5% CO 2 cultured in a 37°C incubator. Subculture once every 3 days, and start the experiment when the cells enter the logarithmic growth phase after 2-3 passages.

[0118] Experimental steps: (1) Take the cultured cells in the logarithmic growth phase, blow them out evenly, and prepare a single cell suspension;

[0119] (2) Adjust the cell concentration to 2×10 with RPMI1640 culture medium containing 10% FBS 5 / mL, seeded in 96-well cell culture plate, 100 μL per well, placed at 37°C, 5% CO 2 Cultivate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com