Intercalation hydrotalcite fire retardant and preparation method thereof

A technology of hydrotalcite and flame retardant, which is applied in the field of intercalated hydrotalcite flame retardant and its preparation, can solve the problems of poor heat resistance, large smoke generation, poor polymer compatibility, etc., and achieves improved strength and flame retardancy. performance, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

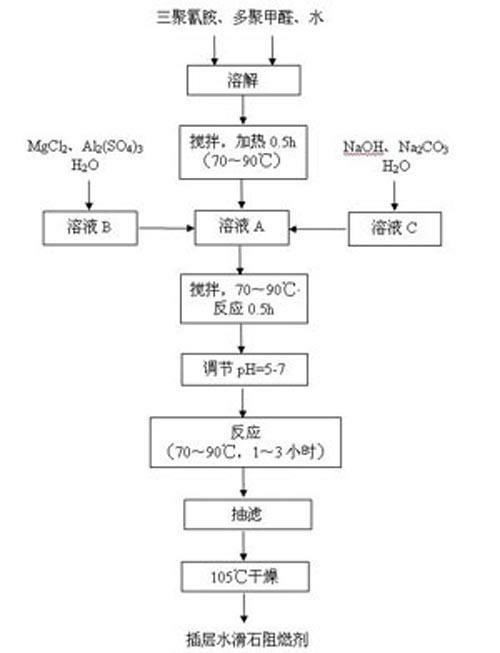

[0024] Embodiment one: preparation process sees appendix figure 1 :

[0025] (1) Add 100 mL of water, 1.26 g of melamine and 0.9 g of low-polymerization paraformaldehyde into a 250 mL three-neck flask, stir well, heat to 80°C in a water bath, and react for 0.5 h to obtain solution A.

[0026] (2) Dissolve 12.18g of magnesium chloride and 6.66g of aluminum sulfate in 50ml of water to form solution B; dissolve 6.4g of sodium hydroxide and 1.06g of sodium carbonate in 50ml of water to form solution C. At the same time, solutions B and C were added dropwise to the above solution A, and the reaction was stirred for 0.5h.

[0027] (3) Adjust the pH value to 7 with hydrochloric acid, reflux at 80°C for 2 hours, filter while hot, wash with hot water until nearly neutral, and dry the product in an oven at 105°C for 24 hours to obtain the product.

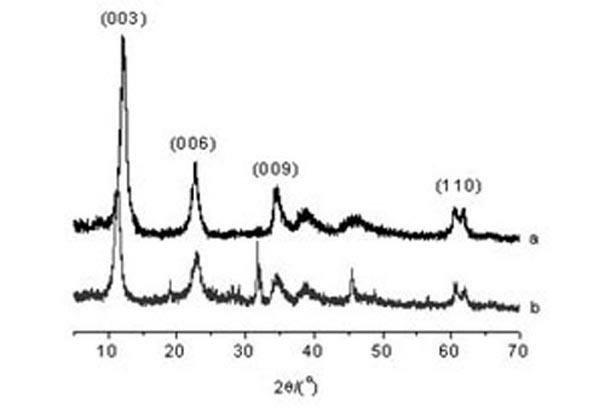

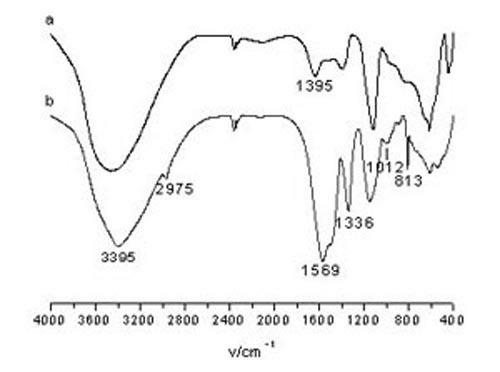

[0028] Carry out XRD analysis to the obtained product, such as figure 2 , the (003), (006) and (009) crystal plane characteristic diffr...

Embodiment 2

[0031] Example two, testing the flame retardancy and mechanical properties of the intercalated hydrotalcite flame retardant

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com