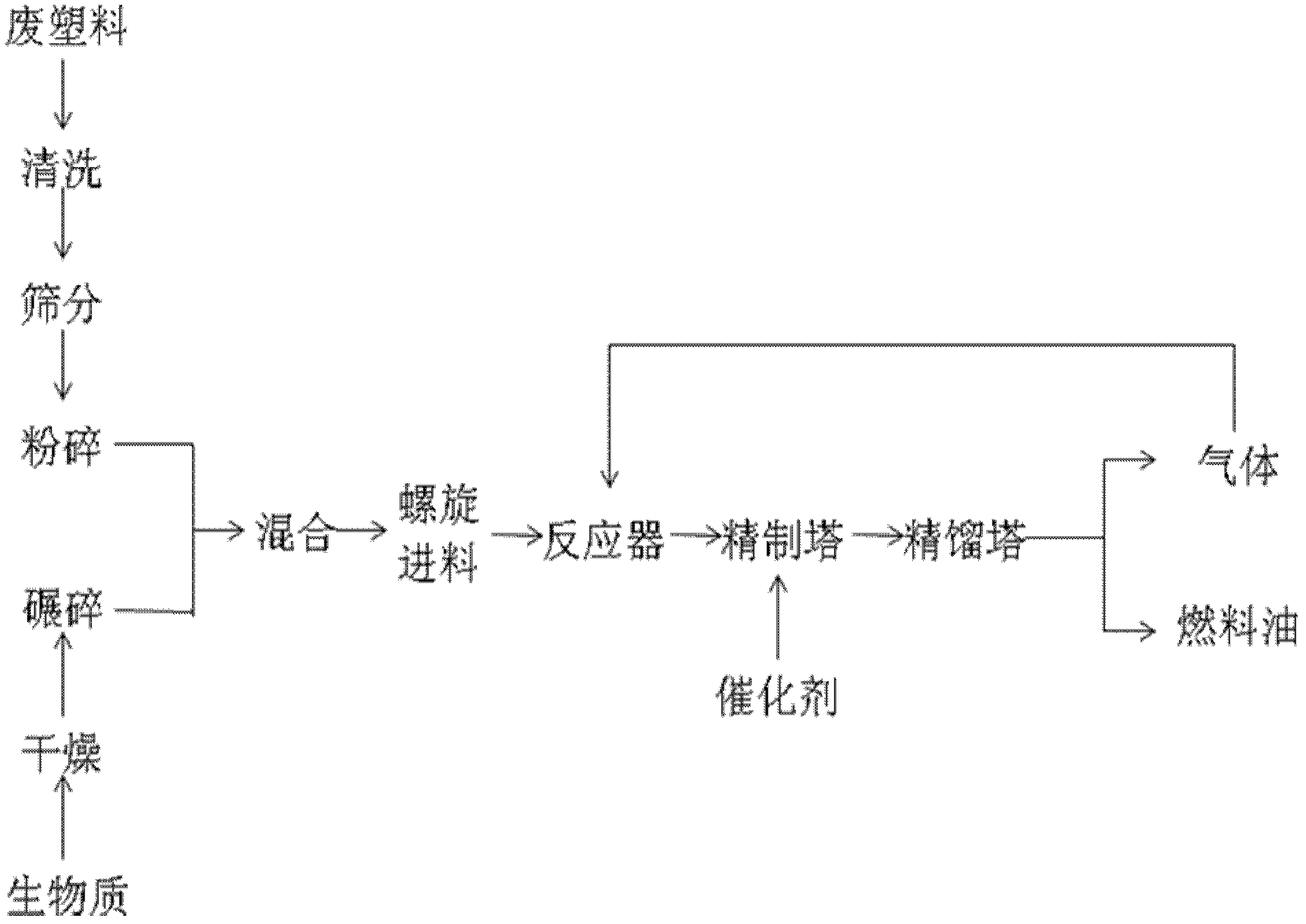

New method for preparing fuel oil by co-pyrolysis of biomass and waste plastic

A technology for waste plastics and biomass, which is used in the preparation of liquid hydrocarbon mixtures and the petroleum industry. It can solve the problems of harsh reaction conditions for separate plastic cracking, and achieve the alleviation of energy crisis, huge social and economic benefits, important social benefits and economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.6 kg of sawdust and 0.4 kg of PP particles according to the mass ratio of 3:2, mix them evenly, and add them to the fixed bed reactor through a screw feeder, and pass the carrier gas argon, the residence time of the gas is 7s, After equilibrating for 30min, start heating, the temperature rises to 450°C, the reaction time is 2h, the oil gas generated by the pyrolysis reaction enters the refining tower, the catalyst is SAPO-31 molecular sieve, and the amount of the catalyst is 10% of the total amount of raw materials, i.e. 100g. After the catalytic upgrading is completed in the refining tower, the obtained liquid product enters the rectifying tower for rectification and separation to obtain fuel oils of different fractions, and the fuel oils include gasoline, diesel oil and heavy diesel oil. The gas products and solid residues obtained by rectification in the rectification tower are directly returned to the fixed-bed reactor for recycling, and finally the specific ...

Embodiment 2

[0033] Weigh 0.5kg of sawdust and 0.5kg of HDPE granules according to the mass ratio of 1:1, mix them evenly, and then add them to the fixed-bed reactor through a screw feeder, pass the carrier gas argon, and the residence time of the gas is 7s. After equilibrating for 30 minutes, start heating, the temperature rises to 450°C, and the reaction time is 2.5 hours. The oil and gas produced by cracking enter the refining tower. The catalyst is SBA-15 molecular sieve, and the amount of catalyst is 10g. After the catalytic upgrading is completed in the refining tower, The obtained liquid product enters the rectification tower for rectification and separation to obtain fuel oils of different fractions, and the fuel oils include gasoline, diesel oil and heavy diesel oil. The gas products and solid residues obtained by rectification in the rectification tower are directly returned to the fixed-bed reactor for recycling, and finally the specific gravity of fuel oil is 0.854, the yield of...

Embodiment 3

[0035] According to the mass ratio of 1:1, weigh 0.5kg of straw and 0.5kg of PP particles, mix them evenly, and add them into the fixed bed reactor through a screw feeder, and pass the carrier gas argon, and the residence time of the gas is 7s. After equilibrating for 30 minutes, start heating, the temperature rises to 480°C, and the reaction time is 3 hours. The oil gas generated by cracking enters the refining tower. The catalyst is FCC catalyst, and the amount of catalyst is 10g. After the catalytic upgrading is completed in the refining tower, the obtained liquid The product enters the rectification tower for rectification and separation to obtain fuel oils of different fractions, which include gasoline, diesel oil and heavy diesel oil. The gaseous products and solid residue obtained by rectification in the rectification tower are directly returned to the fixed-bed reactor for recycling, and finally the specific gravity of fuel oil is 0.836, the yield of oil is 63%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com