Preparation method of cuprous oxide (CU2O) nano octahedral materials

An octahedral and nanotechnology, applied in the field of preparation of cuprous oxide nano-octahedral materials, can solve the problems of high energy consumption, high requirements, and difficult removal of additive residues, and achieve good material performance, low preparation cost and reliable principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

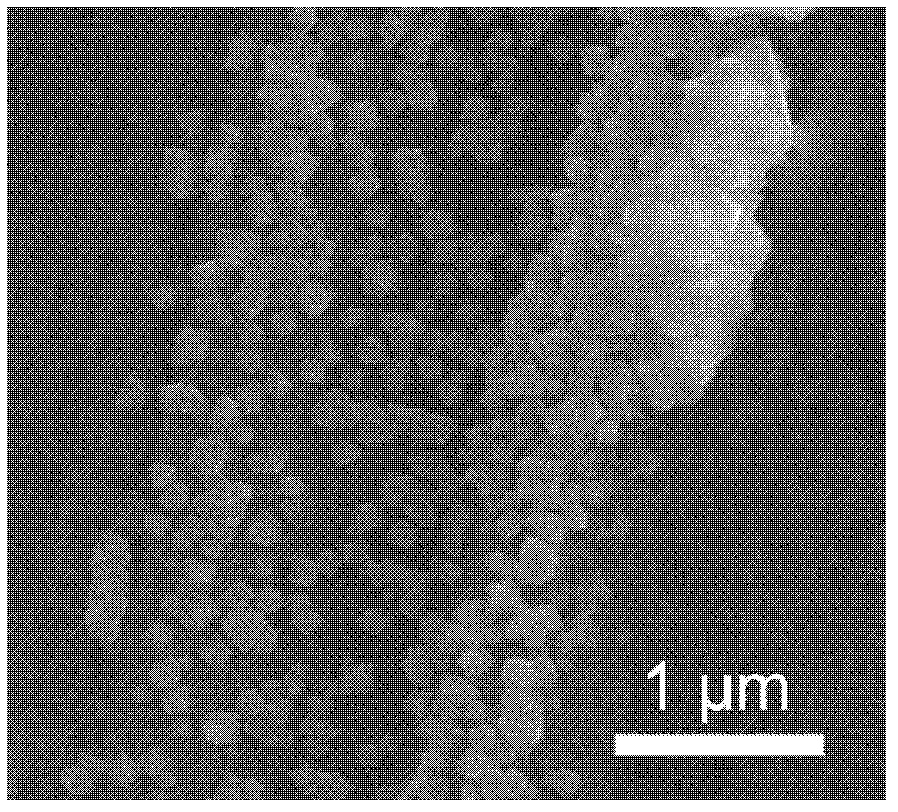

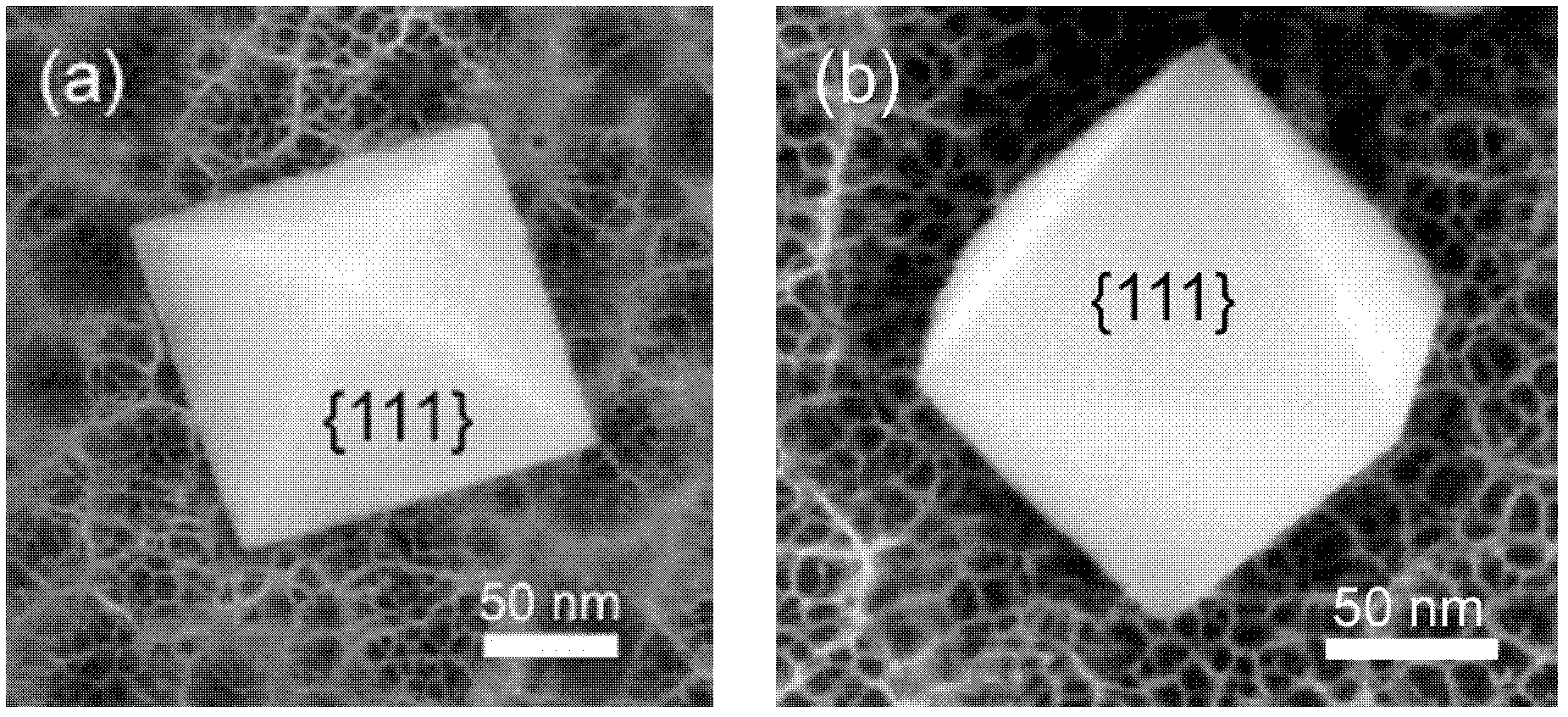

Examples

Embodiment

[0018] This embodiment is implemented according to the following specific steps:

[0019] (1) Preparation of basic solution: Weigh 3.192g of copper sulfate powder into a 50mL beaker, add 11.2mL of lactic acid, mix the two evenly, then dilute with distilled water and stir constantly to prepare a lactic acid concentration of 3mol / L, a copper lactate base solution with a copper sulfate concentration of 0.4mol / L;

[0020] (2) Adjust the pH of the solution: Weigh 40g of sodium hydroxide, dissolve and dilute with distilled water to prepare 250mL of sodium hydroxide solution with a concentration of 4mol / L; use a dropper to add the sodium hydroxide solution dropwise to the above basic solution Keep stirring, adjust its pH to 9 and heat it to 60℃ in a water bath;

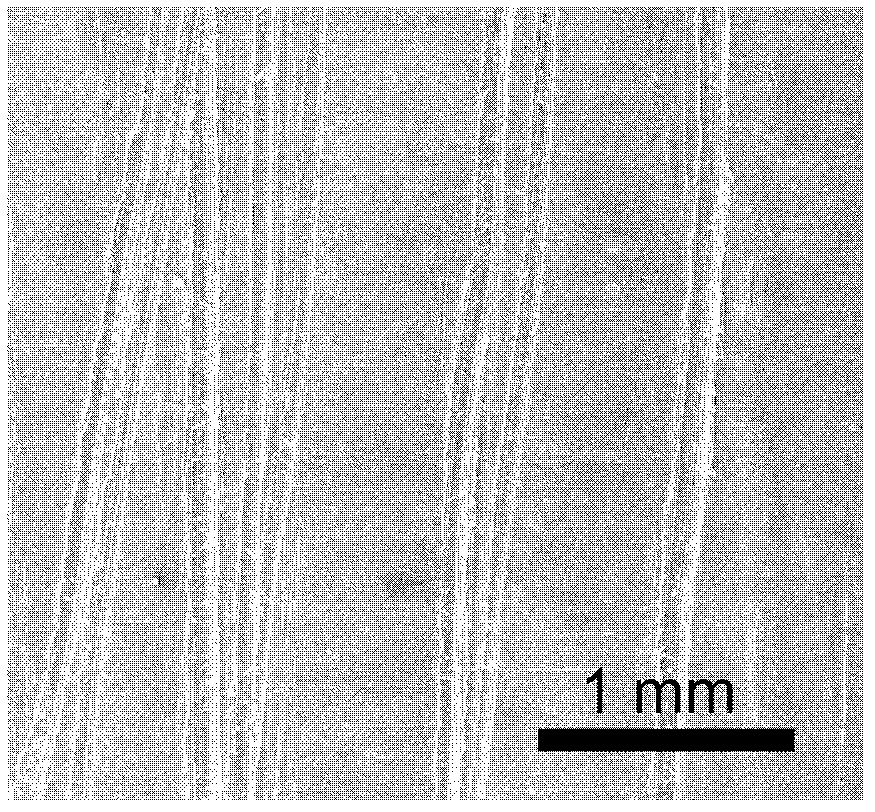

[0021] (3) Conductive substrate treatment: flatten the aluminum sheet, and gently scrape the surface of the aluminum sheet with the back of the curved tweezers to form fine scratches on the surface, and then put the aluminum shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com