Antibacterial polyurethane fiber and preparation method thereof

A technology of spandex fiber and polyurethane is applied in the directions of fiber chemical characteristics, spinning solution preparation, dry spinning method, etc., which can solve the problems of easy elution, weak adsorption, difficult control of silver nanometer size and morphology, etc. Falling off, good spinnability, and the effect of reducing toxicological effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

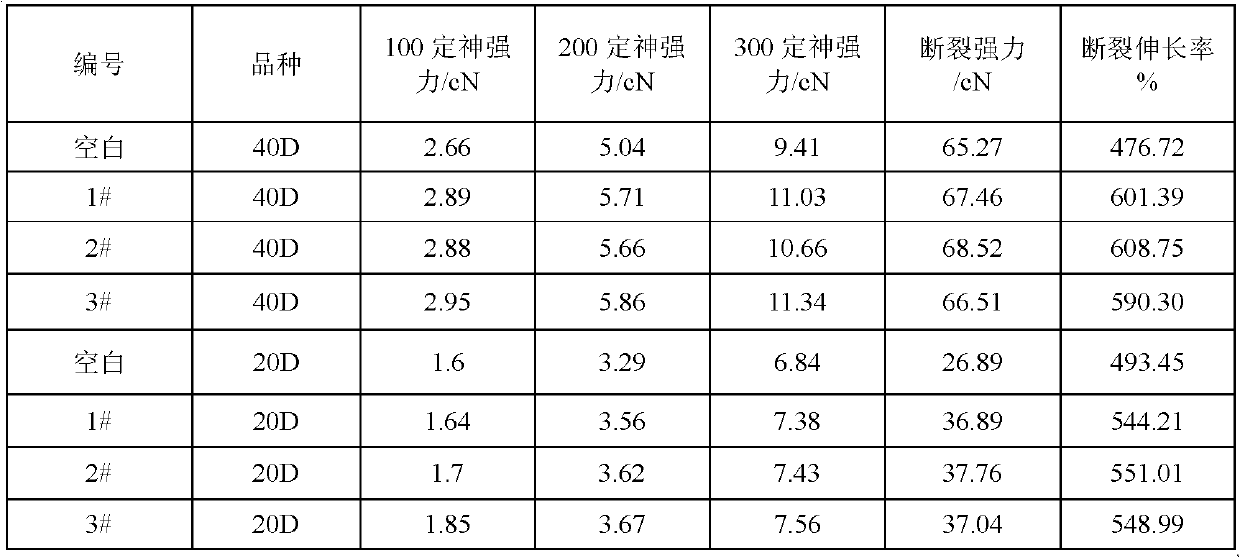

Embodiment 1

[0033] React 170g of polytetramethylene ether glycol and 40g of 4,4-diphenylmethane diisocyanate at 70°C for 40 minutes, then add 340g of N,N-dimethylacetamide to dilute, and quickly add 5g of ethylene diisocyanate while stirring. Amine, 3g2-methylpentanediamine, 1g ethanolamine in 100gN, N-dimethylacetamide solution, carry out chain extension reaction, then add TiO 2 1g, AT2451g, to obtain a polyurethane stock solution.

[0034] Add 20 g of N,N-dimethylacetamide solution with a concentration of 15% polyurethane in the three-necked flask, slowly add 20 g of N,N-dimethylacetamide solution containing 0.25 g of silver nitrate under stirring, and stir at room temperature for 0.5 After ~1 hour, gradually raise the temperature to 70°C, and continue to stir for 3 hours. A golden yellow silver sol is formed, wherein the silver nanoparticles have a particle size of 1nm-100nm. After cooling, they are used as antibacterial agents (containing about 0.15g of nanosilver).

[0035] Add 40g ...

Embodiment 2

[0037] React 170g of polytetramethylene ether glycol and 40g of 4,4-diphenylmethane diisocyanate at 70°C for 40 minutes, then add 340g of N,N-dimethylacetamide to dilute, and quickly add 5g of ethylene diisocyanate while stirring. Amine, 3g2-methylpentanediamine, 1g ethanolamine in 100gN, N-dimethylacetamide solution, carry out chain extension reaction, then add TiO 2 1g, AT2451g, to obtain a polyurethane stock solution.

[0038] Add 30 g of N,N-dimethylacetamide solution with a concentration of 25% polyurethane in the three-necked flask, slowly add 30 g of N,N-dimethylacetamide solution containing 1.0 g of silver nitrate under stirring, and stir at room temperature for 0.5 After ~1 hour, gradually raise the temperature to 70°C, and continue to stir for 3 hours. A golden yellow silver sol is formed, wherein the silver nanoparticles have a particle size of 1nm~100nm, and are used as an antibacterial agent after cooling (containing about 0.63g of nanosilver).

[0039] Add 60g o...

Embodiment 3

[0041]React 170g of polytetramethylene ether glycol and 40g of 4,4-diphenylmethane diisocyanate at 70°C for 40 minutes, then add 340g of N,N-dimethylacetamide to dilute, and quickly add 5g of ethylene diisocyanate while stirring. Amine, 3g2-methylpentanediamine, 1g ethanolamine in 100gN, N-dimethylacetamide solution, carry out chain extension reaction, then add TiO 2 1g, AT2451g, to obtain a polyurethane stock solution.

[0042] Add 100 g of N,N-dimethylacetamide solution with 31% polyurethane in the three-necked flask, slowly add 60 g of N,N-dimethylacetamide solution containing 2.5 g of silver nitrate under stirring, and stir at room temperature for 0.5 ~1 hour. Gradually raise the temperature to 70°C and continue to stir for 3 hours to form a golden yellow silver sol, wherein the silver nanoparticles have a particle size of 1nm to 100nm and are used as an antibacterial agent after cooling (containing about 1.6g of nanosilver).

[0043] Add 160g of antibacterial agent (con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com